Easy-to-uncover film material capable of resisting high-temperature cooking and preparation method thereof

A film material and high-temperature-resistant technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of poor sealing performance and barrier performance of packaging bags, poor high and low temperature resistance of PE film, and content Leakage and overflow problems, to achieve good transparency, low heat-sealing initiation temperature, and improve sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

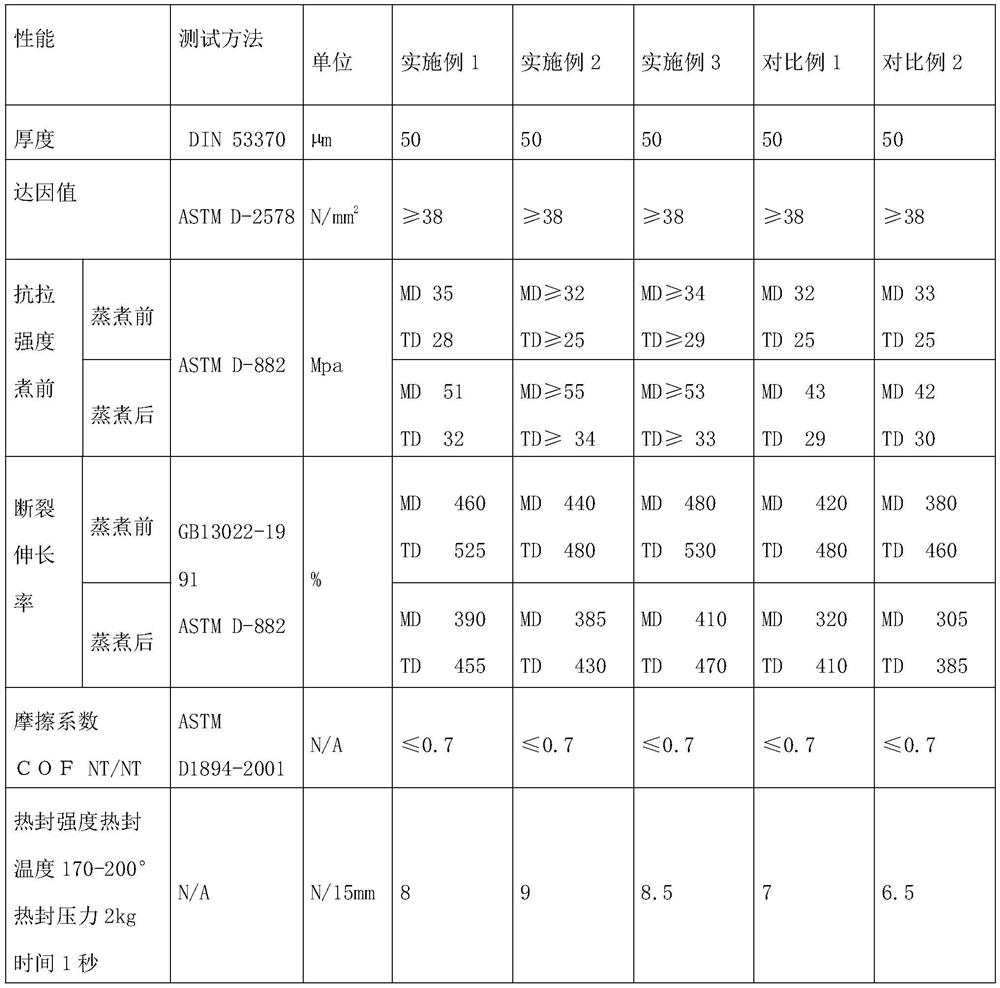

Examples

Embodiment 1

[0019] An easy-to-remove film material that can withstand high-temperature cooking is co-extruded from a corona layer, an intermediate layer, and a heat-sealing layer; the mass ratio of the corona layer, intermediate layer, and heat-sealing layer is 7:10:3 ;

[0020] The corona layer material is a mixture of metallocene medium density polyethylene 50wt% and high density polyethylene 50wt%;

[0021] The material of the middle layer is metallocene high-density polyethylene;

[0022] The heat-sealing layer material is formed by copolymerization of high-density polyethylene (HDPE), polypropylene (PP) and polybutene (PB1);

[0023] Wherein, the density of the metallocene medium density polyethylene is 0.934g / cm 3 , the melt index is 0.9g / 10min; the density of the high-density polyethylene is 0.961g / cm 3 , the melt index is 0.85g / 10min; the melt index of the metallocene high-density polyethylene is 0.7g / 10min.

Embodiment 2

[0025] An easy-to-remove film material that can withstand high-temperature cooking is co-extruded from a corona layer, an intermediate layer, and a heat-sealing layer; the mass ratio of the corona layer, intermediate layer, and heat-sealing layer is 7:10:3 ;

[0026] The corona layer material is a mixture of metallocene medium density polyethylene 40wt% and high density polyethylene 60wt%;

[0027] The material of the middle layer is metallocene high-density polyethylene;

[0028] The heat-sealing layer material is formed by copolymerization of high-density polyethylene (HDPE), polypropylene (PP) and polybutene (PB1);

[0029] Wherein, the density of the metallocene medium density polyethylene is 0.934g / cm 3 , the melt index is 0.9g / 10min; the density of the high-density polyethylene is 0.961g / cm 3 , the melt index is 0.85g / 10min; the melt index of the metallocene high-density polyethylene is 0.7g / 10min.

Embodiment 3

[0031] An easy-to-remove film material that can withstand high-temperature cooking is co-extruded from a corona layer, an intermediate layer, and a heat-sealing layer; the mass ratio of the corona layer, intermediate layer, and heat-sealing layer is 7:10:3 ;

[0032] The corona layer material is metallocene polypropylene;

[0033] The material of the middle layer is metallocene high-density polyethylene;

[0034] The heat-sealing layer material is formed by copolymerization of high-density polyethylene (HDPE), polypropylene (PP) and polybutene (PB1);

[0035] Wherein, the density of the high-density polyethylene is 0.961g / cm 3 , the melt index is 0.85g / 10min; the melt index of the metallocene high-density polyethylene is 0.7g / 10min.

[0036] The preparation method of the easy-to-remove film material in the above embodiment is to add the corona layer, intermediate layer and heat-sealing layer materials into the extruder to heat and melt them, and the melted materials of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com