High-sodium low-rank coal flotation sodium removal method and system

A low-rank coal, sodium removal technology, applied in flotation, chemical instruments and methods, wet separation, etc., can solve the problems of high inertinite content, unfavorable combustion utilization, hydrochloric acid corrosion equipment, etc., to reduce the content of alkali metals , reduce ash content, improve quality and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

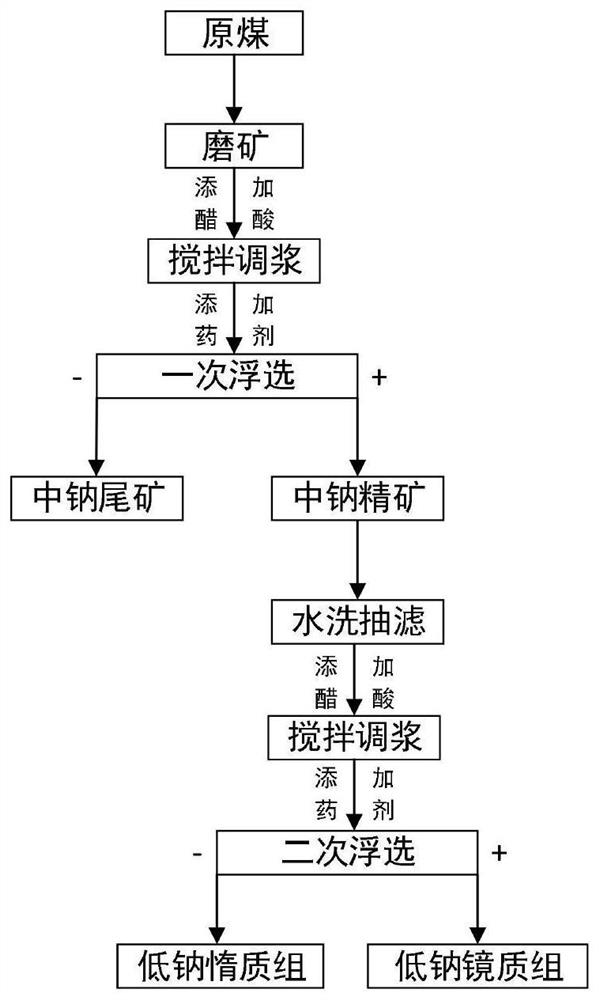

[0027] S1: Grinding high-sodium and low-rank coal into fine-grained raw coal of 5-500 μm;

[0028] S2: Add fine-grained raw coal and 70°C, 3% acetic acid solution into the primary slurry mixing tank to make coal slurry. The mass ratio of acetic acid solution to fine-grained raw coal is 10:1, and stir at a speed of 1000r / min. 10 minutes to fully mix the coal slurry, then add n-octanoic acid and fusel alcohol to the primary slurry mixing tank in turn, stir for 3 minutes and 1 minute respectively, feed the prepared coal slurry into the primary flotation machine for flotation, and collect the primary The foam product and the residual pulp of the primary selection complete a flotation process; the primary foam product is medium-sodium concentrate, and the residual pulp of the primary selection is medium-sodium tailings; the primary foam product is washed and filtered to obtain medium-sodium clean coal;

[0029] S3: Add medium-sodium clean coal and 70°C, 3% acetic acid solution into...

Embodiment 2

[0034] S1: Grinding high-sodium and low-rank coal into fine-grained raw coal of 5-500 μm;

[0035] S2: Add fine-grained raw coal and 90°C, 5% acetic acid solution into the primary slurry mixing tank to make coal slurry. The mass ratio of acetic acid solution to fine-grained raw coal is 10:1, and stir at a speed of 1000r / min to prepare the slurry 10 minutes to fully mix the coal slurry, then add n-octanoic acid and fusel alcohol to the primary slurry mixing tank in turn, stir for 3 minutes and 1 minute respectively, feed the prepared coal slurry into the primary flotation machine for flotation, and collect the primary The foam product and the residual pulp of the primary selection complete a flotation process; the primary foam product is medium-sodium concentrate, and the residual pulp of the primary selection is medium-sodium tailings; the primary foam product is washed and filtered to obtain medium-sodium clean coal;

[0036]S3: Add medium-sodium clean coal and 90°C, 5% aceti...

Embodiment 3

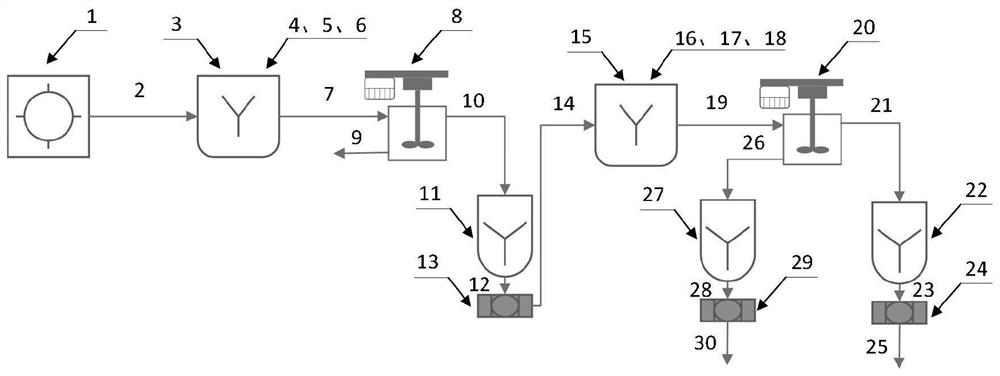

[0041] A high-sodium and low-rank coal flotation desodination system, including: a grinding machine 1, the lower part of the grinding machine 1 is connected to a primary selection slurry tank 3 through a fine-grained raw coal conveyor 2, and the primary selection slurry tank 3 enters the flotation tank through the primary selection The pulp pipeline 7 is connected to the primary flotation machine 8, the primary flotation machine 8 is provided with a primary tailings discharge pipeline 9 and a primary concentrate discharge pipeline 10, and the primary flotation machine 8 passes through the primary concentrate discharge pipeline 10 It is connected with the clean coal water washing bucket 11, the clean coal water washing bucket 11 is connected with the concentrate filter 13 through the water washing concentrate discharge pipe 12, and the concentrate filter 13 is connected with the sorting and mixing tank 15 through the clean coal conveyor 14, and the sorting and mixing The barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com