Ultraviolet light blocking hydrogel containing immobilized nanoparticles and preparation method thereof

A nanoparticle and hydrogel technology, which is applied in the field of ultraviolet light blocking hydrogel and its preparation, can solve the problems of phase separation, agglomeration, and biological toxicity, and achieve the solution of overflow and agglomeration, mild reaction conditions, and controlled reaction degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

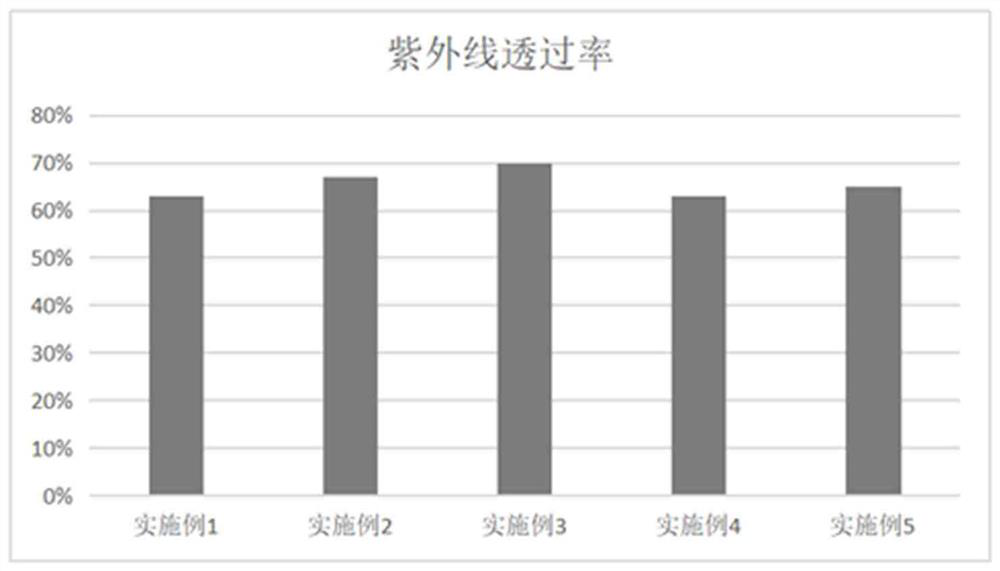

Examples

Embodiment 1

[0028] Step 1: Add 50ml of water and ethylene glycol mixed solvent with a volume ratio of 3:1 into the beaker, and add 30g of hydroxyethyl methacrylate and ethylene glycol dimethacrylate with a mass ratio of 1:0.05:0.015 And 1-allylpiperazine mixture, ultrasonically dispersed for 15min at low temperature, then add 0.1g azobisisobutyronitrile and ultrasonically divided at low temperature for 45min, after ultrasonic dispersion is completed, pour into the mold, stand at 40 ° C for 9h , heated to 60°C and kept for 12h to obtain an intermediate product;

[0029] Step 2: Put the intermediate product obtained in step 1 into a three-necked flask, add 200ml of deionized water to soak for 2 days, replace the deionized water every 8h during the period, and then pass nitrogen for 30min, and then move the whole system into a shaking shaker, Adjust the shaking speed to 200rpm / min, first add 60mlm of sodium borohydride solution with a concentration of 0.3g / ml, then dropwise add 55ml of ferri...

Embodiment 2

[0033] Step 1: Add 60ml of water and ethylene glycol mixed solvent with a volume ratio of 3:1 into the beaker, and add 30g of hydroxyethyl methacrylate and ethylene glycol dimethacrylate with a mass ratio of 1:0.05:0.05 and N-ethylmethacrylamine mixture, ultrasonically dispersed at low temperature for 25min, then added 0.07g azobisisobutyronitrile and ultrasonically dispersed at low temperature for 40min. After ultrasonic dispersion was completed, poured into the mold and stood at 50°C for 10h Then, the temperature was raised to 60 °C and kept for 24 h to obtain an intermediate product;

[0034] Step 2: Put the intermediate product obtained in step 1 into a three-necked flask, add 200ml of deionized water to soak for 3 days, replace the deionized water every 8h during the period, and then pass nitrogen for 50min, and then move the whole system into a shaking shaker, Adjust the shaking speed to 200rpm / min, first add 100ml of sodium borohydride solution with a concentration of 0...

Embodiment 3

[0038] Step 1: Add 65ml of water and ethylene glycol mixed solvent with a volume ratio of 4:1 into the beaker, and add 45g of hydroxyethyl methacrylate and ethylene glycol dimethacrylate with a mass ratio of 1:0.05:0.015 And 1-allylpiperazine mixture, ultrasonically dispersed for 30min at low temperature, then add 0.8g azobisisobutyronitrile and ultrasonically dispersed at low temperature for 50min, after ultrasonic dispersion is completed, pour into the mold, stand at 55 ℃ for 18h , heated to 80°C and kept for 30h to obtain an intermediate product;

[0039] Step 2: Put the intermediate product obtained in step 1 into a three-necked flask, add 300ml of deionized water for 2 days, replace the deionized water every 8h during the period, and then pass nitrogen for 50min, and then move the whole system into a shaking shaker, Adjust the shaking speed to 250rpm / min, first add 125ml of sodium borohydride solution with a concentration of 0.3g / ml, then dropwise add 95ml of ferric chlor...

PUM

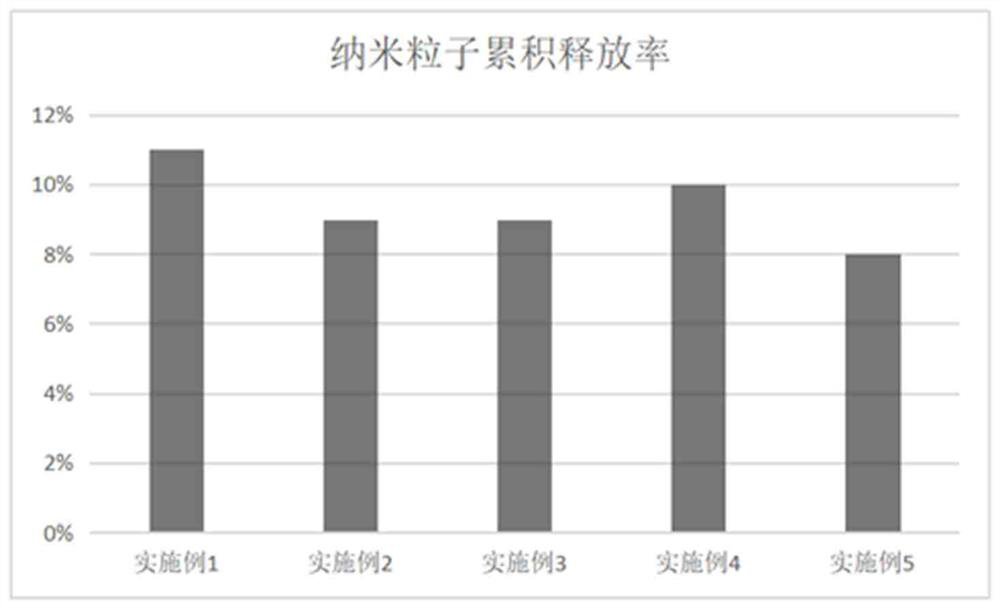

| Property | Measurement | Unit |

|---|---|---|

| cumulative release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com