Stretchable conductive hydrogel with high water-retaining property and preparation method thereof

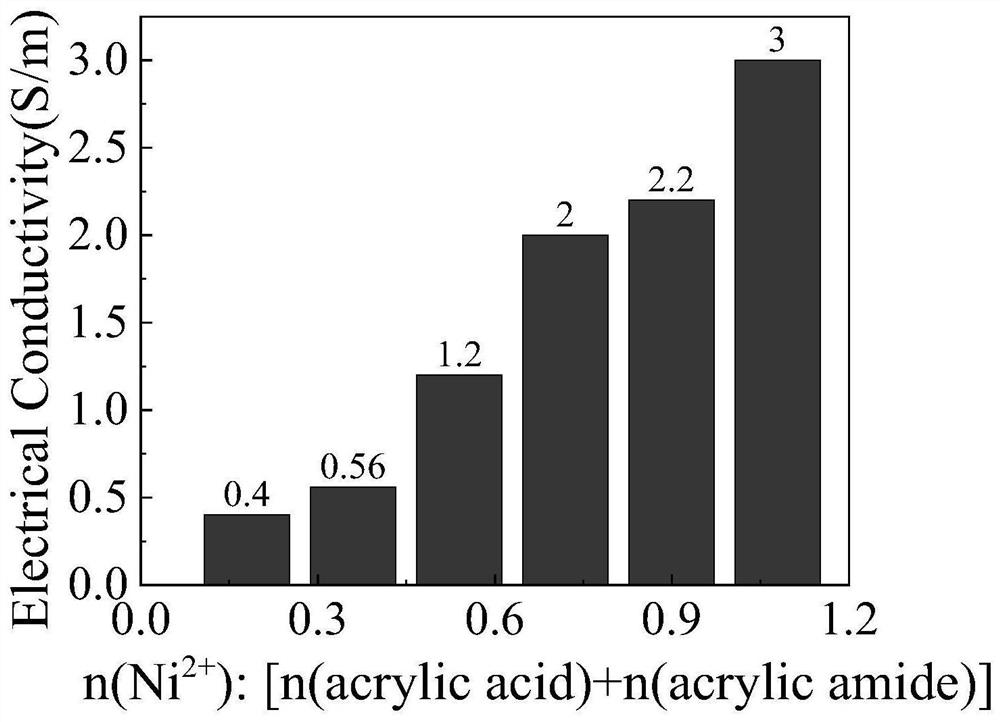

A conductive hydrogel and water retention technology, applied in the field of functional polymer preparation, can solve problems such as collapse, weak adhesion, and conductivity changes, and achieve high conductivity, improved water retention, and high tensile properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

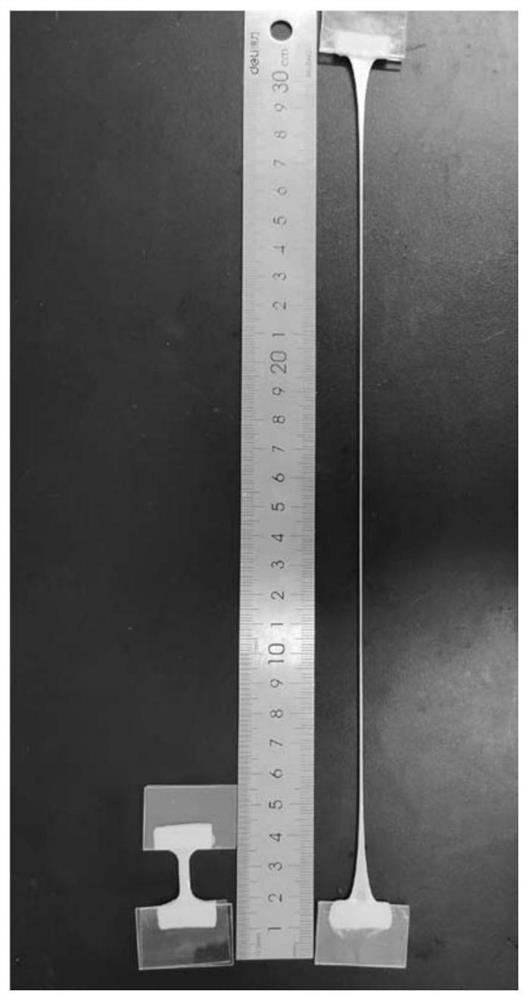

Image

Examples

Embodiment 1

[0025] (1) First, add 1g of acrylamide and 3g of acrylic acid to a beaker, dissolve them in 10mL of deionized water, add a magnet and stir on a magnetic stirrer until the solids are completely dissolved; then add 0.008g of N,N- Methylenebisacrylamide powder, drop into 0.4mL tetramethylethylenediamine solution, stir magnetically again until all the solids are dissolved; put the prepared solution into a vacuum drying oven to exhaust for 10min.

[0026] (2) Weigh 0.04g of potassium persulfate powder and dissolve it in 10mL of deionized water, and magnetically stir until completely dissolved. And add it to the solution obtained in step (1), put it into a vacuum drying oven to exhaust gas for 10 minutes. Pour the prepared solution into the mold, and the time of ultraviolet light triggering is 2h.

Embodiment 2

[0028] (1) First, add 1g of acrylamide, 3g of acrylic acid, 1.331g of nickel chloride hexahydrate into a beaker, dissolve in 10mL of deionized water, add magnets and stir on a magnetic stirrer until the solids are completely dissolved; then in the above solution Add 0.008g of N,N-methylenebisacrylamide powder, drop into 0.4mL of tetramethylethylenediamine solution, stir magnetically again until all the solids are dissolved; put the prepared solution into a vacuum drying oven to exhaust for 10min .

[0029] (2) Weigh 0.04g of potassium persulfate powder and dissolve it in 10mL of deionized water, and magnetically stir until completely dissolved. And add it to the solution obtained in step (1), put it into a vacuum drying oven to exhaust gas for 10 minutes. Pour the prepared solution into the mold, and the time of ultraviolet light triggering is 2h.

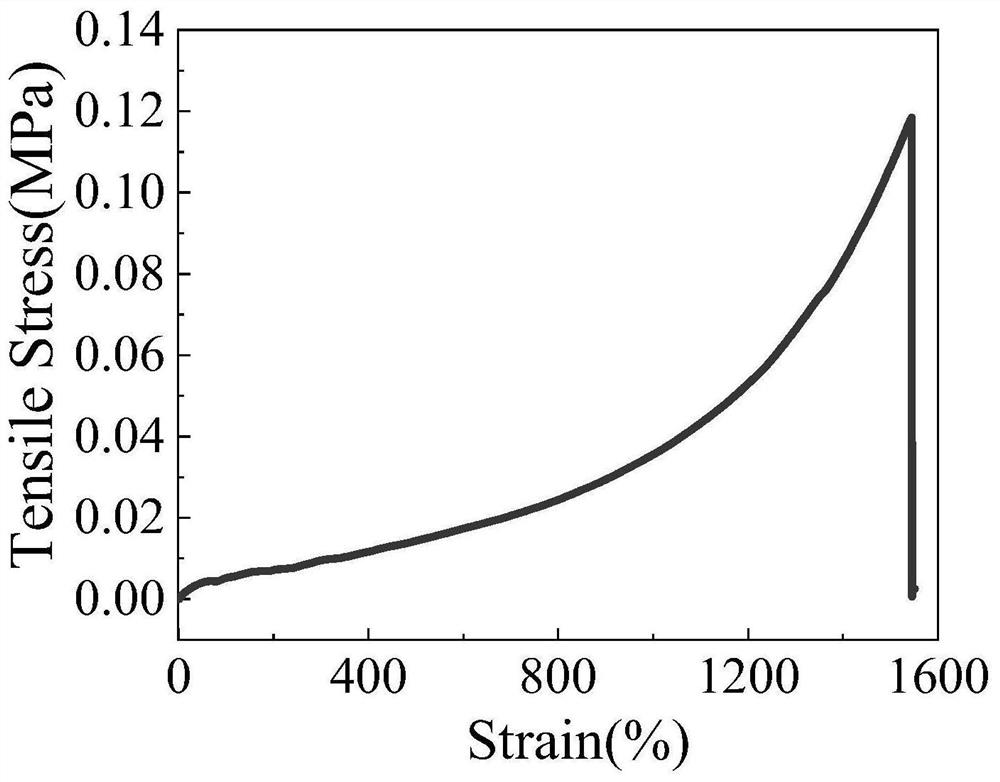

[0030] (3) After the hydrogel was placed at room temperature for 24 hours, the tensile test was performed.

Embodiment 3

[0032] (1) First, add 1g of acrylamide, 3g of acrylic acid, 1.331g of nickel chloride hexahydrate into a beaker, dissolve in 10mL of deionized water, add magnets and stir on a magnetic stirrer until the solids are completely dissolved; then in the above solution Add 0.008g of N,N-methylenebisacrylamide powder, drop into 0.4mL of tetramethylethylenediamine solution, stir magnetically again until all the solids are dissolved; put the prepared solution into a vacuum drying oven to exhaust for 10min .

[0033] (2) Weigh 0.005 g of carboxymethyl hydroxyethyl cellulose and dissolve it in 10 mL of deionized water, and magnetically stir until completely dissolved.

[0034] (3) Weigh 0.04g of potassium persulfate powder and dissolve it in 10mL of deionized water, and magnetically stir until completely dissolved. And the prepared solution and the solution obtained in step (2) are added to the solution obtained in step (1), and put into a vacuum drying oven to exhaust gas for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com