Flexible double-sided solar cell module and preparation method thereof

A solar cell and flexible technology, applied in the field of solar cells, can solve the problems of low power generation efficiency of flexible solar cells, achieve the effect of improving overall competitiveness and increasing power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

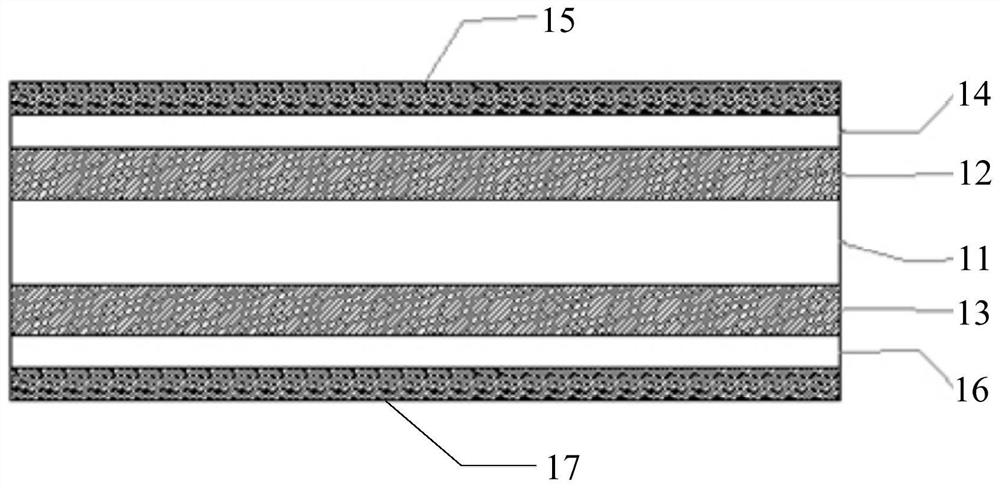

[0060] Such as figure 1 As shown, the embodiment of the present disclosure provides a flexible double-sided solar cell module, including a flexible substrate 11, a first power generation film layer 12, a second power generation film layer 13, a first packaging film layer 14, a flexible front plate 15, a second power generation film layer Two packaging film layers 16 and a flexible backplane 17 .

[0061] The flexible substrate 11 includes at least one of polyimide, stainless steel foil and glass with a thickness smaller than a first preset thickness threshold (ie, ultra-thin glass).

[0062] The flexible substrate 11 can withstand a high temperature of 300 degrees for a long time without deformation and embrittlement.

[0063] The total thickness of the first power generation film layer 12 is not more than 15 μm.

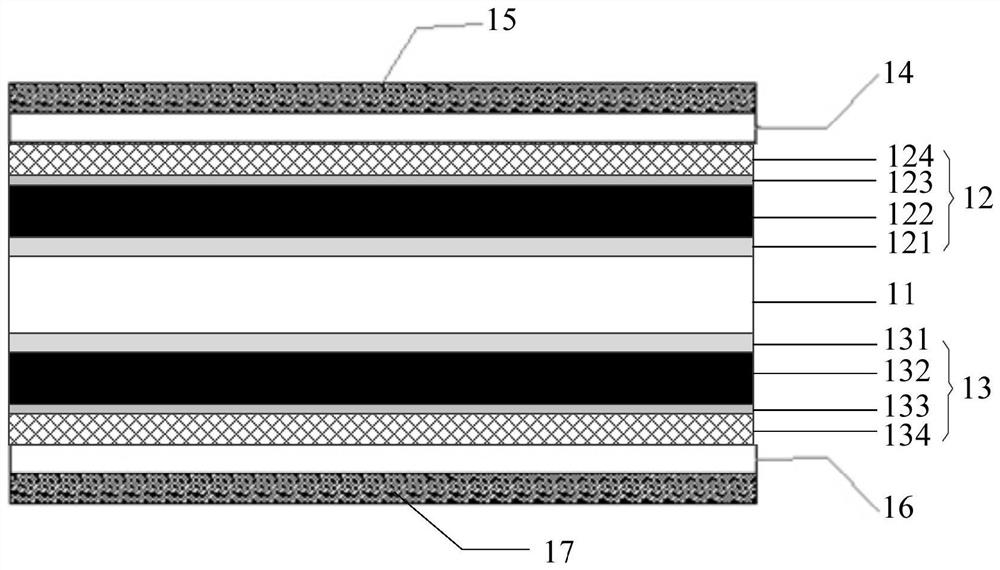

[0064] Such as figure 2 As shown, the first power generation film layer 12 includes a first back contact layer 121 , a first absorption layer 122 , a first buff...

Embodiment 2

[0081] On the basis of the first embodiment, this embodiment provides a method for preparing a flexible double-sided solar cell module. Figure 4 It is a schematic flowchart of a method for preparing a flexible double-sided solar cell module shown in an embodiment of the present disclosure.

[0082] Such as Figure 4 As shown, the preparation method of the flexible double-sided solar cell module of the present embodiment includes the following steps:

[0083] Step S101: if Figure 5 As shown, a flexible substrate 1121 is provided.

[0084] The flexible substrate 11 includes at least one of polyimide, stainless steel foil and glass with a thickness smaller than a first preset thickness threshold (ie, ultra-thin glass).

[0085] The flexible substrate 11 can withstand a high temperature of 300 degrees for a long time without deformation and embrittlement.

[0086] Step S102: if Figure 6 As shown, the first power generation film layer 12 is formed on the flexible substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com