Optical diffusion film and preparation method and application thereof

A technology of optical diffusion and light diffusion particles, which is applied in the field of optical films, can solve problems such as unsatisfactory effects, poor display quality of mobile phone screens, and improved uniformity of light diffusion in backlight modules to achieve haze and light transmittance. Good stability, protection of the light guide plate, and moderate light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

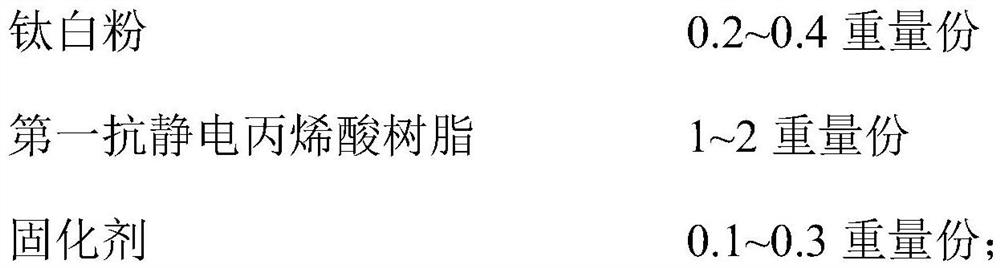

[0086] A mother liquor comprises the following components in parts by weight:

[0087]

[0088] The preparation method of the mother liquor that this preparation example provides specifically comprises the steps:

[0089] (1) the first light diffusion particle (particle diameter is 3 μm, material is PMMA cross-linked body, the second light diffusion particle (particle diameter is 8 μm, material is PMMA micropowder) and titanium dioxide are dissolved in butanone and n-propyl ester, Disperse at a rotational speed of 500 rpm to obtain the first mixture;

[0090] (2) Mix the first mixture obtained in step (1) with the first acrylic resin (Suzhou Litianrun, LK-331), and disperse for 30 minutes at a rotating speed of 1000 rpm to obtain the second mixture;

[0091] (3) Mix the second mixture obtained in step (2), dispersant (BYK-111), leveling agent (BYK-54) and defoamer (BYK-057), and disperse at 2000 rpm for 60 minutes to obtain the first three mixtures;

[0092] (4) Mix the ...

preparation example 2

[0094] A mother liquor comprises the following components in parts by weight:

[0095]

[0096] The preparation method of the mother liquor that this preparation example provides specifically comprises the steps:

[0097] (1) Dissolve the third light-diffusing particles (particle size is 8 μm, material is PMMA cross-linked) in methyl ethyl ketone and n-propyl ester, and disperse at 500 rpm to obtain the first mixture;

[0098] (2) Mix the first mixture obtained in step (1) with the second acrylic resin (Suzhou Litianrun, LK-332), and disperse for 30 minutes at a rotating speed of 1000 rpm to obtain the second mixture;

[0099] (3) Mix the second mixture obtained in step (2), dispersant (BYK-111), leveling agent (BYK-54) and defoamer (BYK-057), and disperse at 2000 rpm for 60 minutes to obtain the first three mixtures;

[0100] (4) Mix the third mixture obtained in step (3) with a curing agent (N3300), and disperse for 20 minutes at a rotational speed of 5000 rpm to obtain...

Embodiment 1

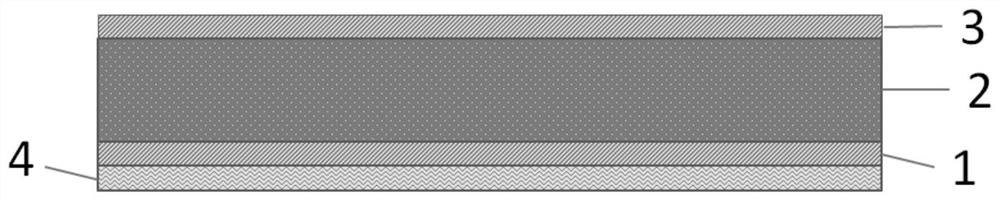

[0127] A kind of optical diffusion film, its cross-sectional structure is as figure 1 As shown, it includes: a protective film 4, a first optical diffusion layer 1, a base layer 2 and a second optical diffusion layer 3;

[0128] Wherein, the thickness of the first optical diffusion layer and the second optical layer is 10 μm, and the thickness of the base layer is 50 μm;

[0129] The preparation method of the optical diffusion film provided in this embodiment comprises the following steps:

[0130] (1) Coating the preparation raw materials of the first optical diffusion layer (preparation example 1) and the preparation raw materials of the second optical diffusion layer (preparation example 2) on both sides of the base layer (PET film) respectively to obtain a diffusion film;

[0131] (2) Attaching a protective film (PET film) to the surface of the first optical diffusion layer of the diffusion film obtained in step (1) to obtain the optical diffusion film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com