Preparation method of temperature-adjusting fiber, temperature-adjusting fiber and fabric

A technology of temperature-regulating fibers and primary fibers, applied in the field of materials, can solve problems such as damage to fiber temperature-regulating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

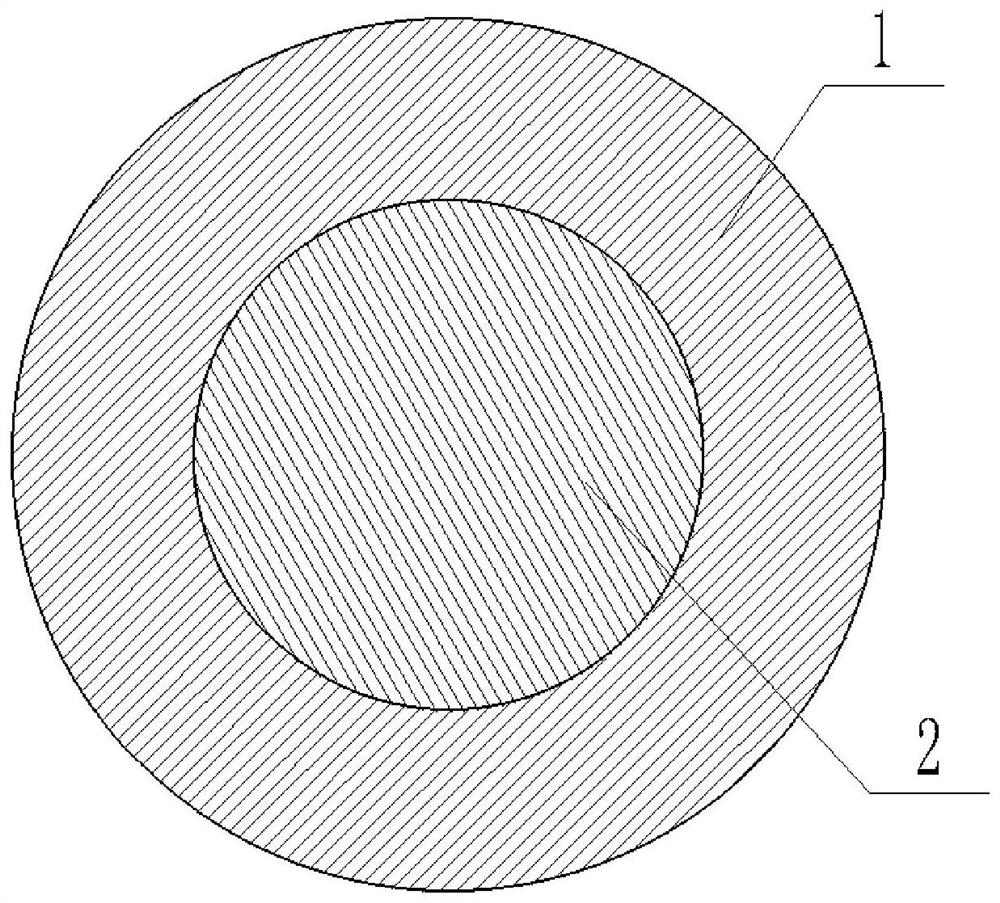

[0036] The preparation method of the temperature-regulating fiber provided by the embodiment of the present invention firstly prepares core-shell / phase-change material composite particles, and then prepares the spinning solution, which is spun through a spinneret with a special structure, so that the formed temperature-regulating fiber structure is as follows: figure 1 As shown, the temperature-regulating fiber includes a first part 1 and a second part 2 covered by the first part 1, wherein the first part 1 is formed by a conventional spinning solution, and the second part 2 contains core-shell / phase change material composite particles.

[0037] In order to obtain such figure 1 The temperature-regulating fiber shown, designed as figure 2 In the spinneret structure shown, the spinneret 3 is provided with a first spinneret hole 4 and a second spinneret hole 5 arranged coaxially, and the first spinneret hole 4 is set outside the second spinneret hole 5 , for forming the first p...

Embodiment 1

[0044] A method for preparing a temperature-regulating fiber, comprising the following steps:

[0045] Step 1, preparation of styrene-methyl methacrylate-acrylic acid copolymer / capric acid composite particles:

[0046] The capric acid of 73 parts by weight, the styrene of 22 parts by weight, the methyl methacrylate of 13 parts by weight, the acrylic acid of 3 parts by weight, the silane coupling agent of 0.4 parts by weight and the azobisisobutyronitrile of 0.4 parts by weight in Stir and disperse evenly at 32°C to obtain the first mixed system; stir 3 parts by weight of sodium dodecylsulfonate and 450 parts by weight of deionized water at 30°C to obtain the second mixed system; Under the temperature, mix the first mixing system and the second mixing system evenly, and stir and emulsify at a speed of 6500r / min to prepare an emulsion, and then heat the emulsion at 83°C for 7 hours to polymerize reaction; after the reaction is finished, the reaction product is washed and dried ...

Embodiment 2

[0051] A method for preparing a temperature-regulating fiber, comprising the following steps:

[0052] Step 1, preparation of styrene-methyl methacrylate-acrylic acid copolymer / capric acid composite particles:

[0053] The capric acid of 85 parts by weight, the styrene of 20 parts by weight, the methyl methacrylate of 10 parts by weight, the acrylic acid of 8 parts by weight, the silane coupling agent of 0.35 parts by weight and the azobisisobutyronitrile of 0.4 parts by weight in Stir and disperse evenly at 32°C to obtain the first mixed system; stir 3 parts by weight of sodium dodecylsulfonate and 400 parts by weight of deionized water at 30°C to obtain the second mixed system; Under the temperature, mix the first mixing system and the second mixing system evenly, and stir and emulsify at a speed of 6500r / min to prepare an emulsion, and then heat the emulsion at 83°C for 7 hours to polymerize reaction; after the reaction is finished, the reaction product is washed and dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com