Method for producing L-5-methyltetrahydrofolate by biological method

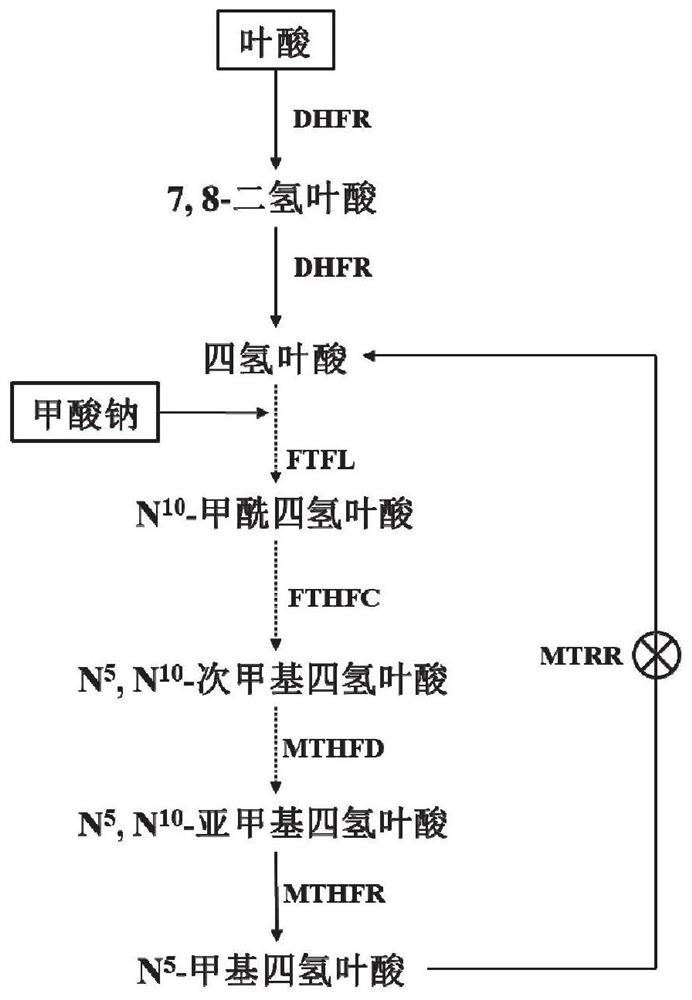

A technology of methyltetrahydrofolate and methylenetetrahydrofolate is applied in the field of producing L-5-methyltetrahydrofolate and producing L-5-MTHF by constructing Escherichia coli engineering bacteria biological method, which can solve the problem of yield Small size, low purity, environmental pollution and other problems, to achieve the effect of saving time, strong specificity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the construction of the engineering bacterium that produces L-5-MTHF

[0042] Take Clostridium autoethanogenum and Methylobacterium extorquens AM1 cells, and extract their genomic DNA from the cells according to the method recommended by the bacterial genomic DNA extraction kit.

[0043] According to the dihydrofolate reductase gene (folA) sequence design shown in nucleotide sequence SEQ ID NO.3 in the known E.coli BL21 (DE3) genome primer folA_F: GGAATTCCATATGATCAGTCTGATTGCGGC and folA_R: CCGCTCGAGTTACCGCCGCTC, with E.coli The BL21(DE3) genome was used as a template to amplify the folA gene, and the PCR cycle parameters were 95°C for 5min; (95°C for 30s, 56°C for 30s, 72°C for 15s); 72°C for 10min, 30 cycles.

[0044] According to the methylenetetrahydrofolate reductase gene (metF) sequence design primer metF_F shown in nucleotide sequence SEQ ID NO.4 in the known E.coli BL21 (DE3) genome: CATGCCATGGGCATGAGCTTTTTTCACG and metF_R: CCCAAGCTTTTATAAACCAGGTCGA...

Embodiment 2

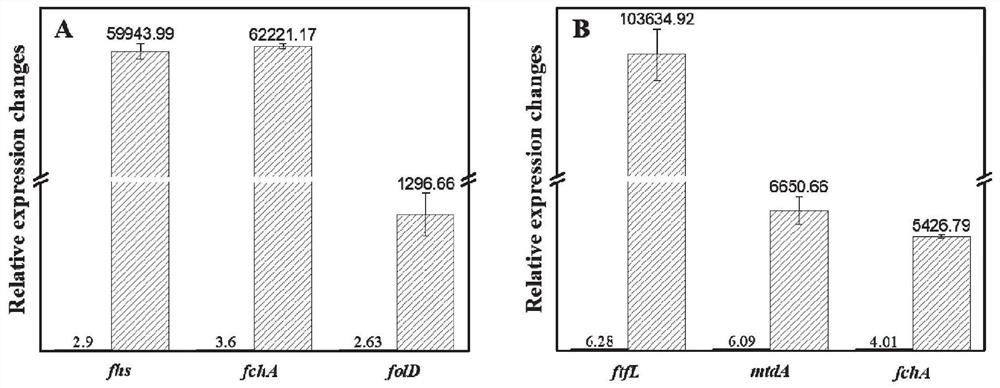

[0061] Example 2: Analysis of exogenous gene transcription level of engineering strains

[0062] BL21-WL and BL21(ΔmetH)-C1T engineering bacteria are cultivated to OD in the medium in embodiment 1 600nm When the value is 0.8, take 1ml of bacterial liquid as the sample before induction. Then add IPTG with a final concentration of 0.8mM to induce for 12h, take 1ml of bacterial solution, and dilute to OD with sterile normal saline 600nm The value is 0.8, which is used as the bacterial liquid after induction treatment. The collected cells were extracted with the Easypure RNA Kit, and then reverse-transcribed with the AccuRT Genomic DNA Removal kit and 5×All-In-OneMasterMix to generate cDNA (25°C 10min; 42°C 15min; 85°C 5min), and the cDNA was diluted to the same concentration as a template for qPCR analysis. qPCR with Top Green qPCR Supermix was used as the dye, and LightCycler 480 was used for the reaction.

[0063] Using the expression level of the 16s rRNA gene as an inte...

Embodiment 3

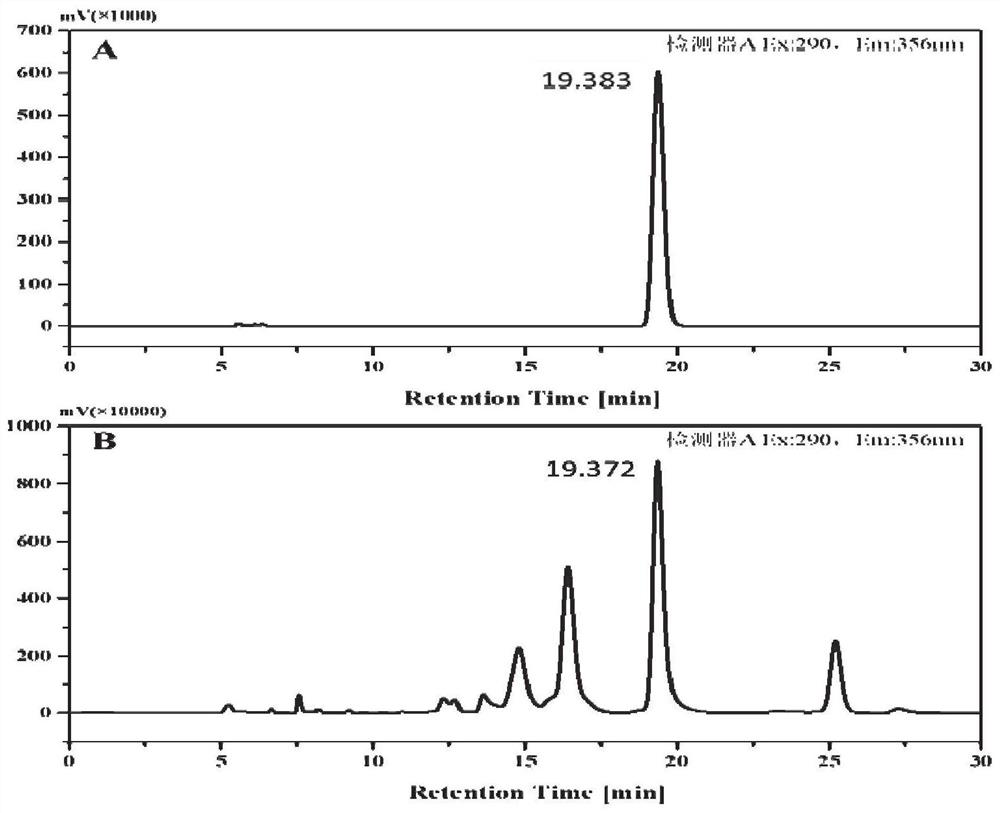

[0070] Embodiment 3: the yield calculation method and LC-MS analysis of L-5-MTHF in engineering bacteria

[0071] (1) The broken method of BL21-WL or BL21(ΔmetH)-C1T engineering bacterium cell of gaining in embodiment 1 is: the engineering bacterium cell that obtains after centrifugation is in the anaerobic box with ascorbic acid containing 0.1% and containing 0.1% mercapto Resuspend in 50 mM Tris-HCl (pH 7.2) in ethanol to the same volume, seal it in an anaerobic vial with a rubber stopper, and break the cells by boiling in a water bath at 100°C for 10 minutes to obtain a cell disruption solution containing L-5-MTHF. Immediately after that, the supernatant was collected by centrifugation at 15,000 rpm at 4°C for 15 min, and fresh mouse serum (100 μl·ml -1 ), reacted at 37°C for 3h, boiled for 5min to terminate the reaction, centrifuged to take the supernatant, filtered through a 0.22μm cellulose acetate filter membrane, and put the filtrate into a liquid phase vial.

[0072]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com