Method for adjusting water content in carbonyl synthesis acetic acid system of iridium catalytic system

A catalytic system, oxo synthesis technology, applied in carbon monoxide reaction to prepare carboxylic acid, organic chemistry, etc., can solve the problems of reducing device production capacity, reducing catalyst solubility, increasing separation energy consumption, etc., to achieve increased output, high product quality, and composition stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

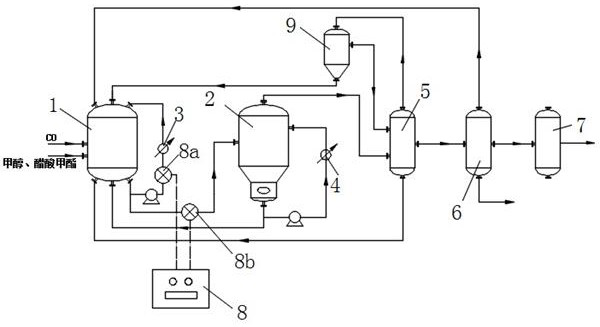

[0027] The feed rate of methanol is 0.5 tons / hour, the feed rate of methyl acetate is 0.5 tons / hour, under the conditions of temperature 190 ° C and pressure 3.0 MPa, the iridium complex of CO and methanol at 2000 ppm and cocatalyst methyl iodide The reaction is carried out in the fluid agitation reactor 1 under the action; the first water quantity detection probe 8a is set on the branch pipe connected to the circulating cooler 3, and the second water quantity detection probe 8b is set on the branch pipe connected to the flasher 2, and the water quantity detector 8 Take the average value of the detection amounts of the two detection probes to obtain a water content of 6% in the reaction solution.

[0028] Afterwards, the reaction solution flows out from the fluid agitation reactor 1 and enters the evaporator for flash evaporation, and performs preliminary separation of the mother liquor and crude acetic acid. The mother liquor returns to the reactor to continue the reaction. E...

Embodiment 2

[0030] The feed rate of methanol is 1.25 tons / hour, the feed rate of methyl acetate is 0.25 tons / hour, under the conditions of temperature 195 ° C and pressure 3.2 MPa, the iridium complex of CO and methanol at 1800 ppm and cocatalyst methyl iodide The reaction is carried out in the fluid agitation reactor 1 under the action; the first water quantity detection probe 8a is set on the branch pipe connected to the circulating cooler 3, and the second water quantity detection probe 8b is set on the branch pipe connected to the flasher 2, and the water quantity detector 8 Take the average value of the detection amounts of the two detection probes to obtain a water content of 8% in the reaction solution.

[0031] The reaction liquid flows out from the fluid agitation reactor 1 and enters the evaporator for flash evaporation to perform preliminary separation of the mother liquor and crude acetic acid. The mother liquor returns to the reactor to continue the reaction. Enter the water ...

Embodiment 3

[0033] The feed rate of methanol is 0.5 tons / hour, the feed rate of methyl acetate is 0.75 tons / hour, under the conditions of temperature 185 ° C and pressure 3.0 MPa, the iridium complex of CO and methanol at 1500 ppm and cocatalyst methyl iodide The reaction is carried out in the fluid agitation reactor 1 under the action; the first water quantity detection probe 8a is set on the branch pipe connected to the circulating cooler 3, and the second water quantity detection probe 8b is set on the branch pipe connected to the flasher 2, and the water quantity detector 8 Take the average value of the detection amounts of the two detection probes to obtain a water content of 4.5% in the reaction solution.

[0034] The reaction liquid flows out from the fluid agitation reactor 1 and enters the evaporator for flash evaporation to perform preliminary separation of the mother liquor and crude acetic acid. The mother liquor returns to the reactor to continue the reaction. Enter the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com