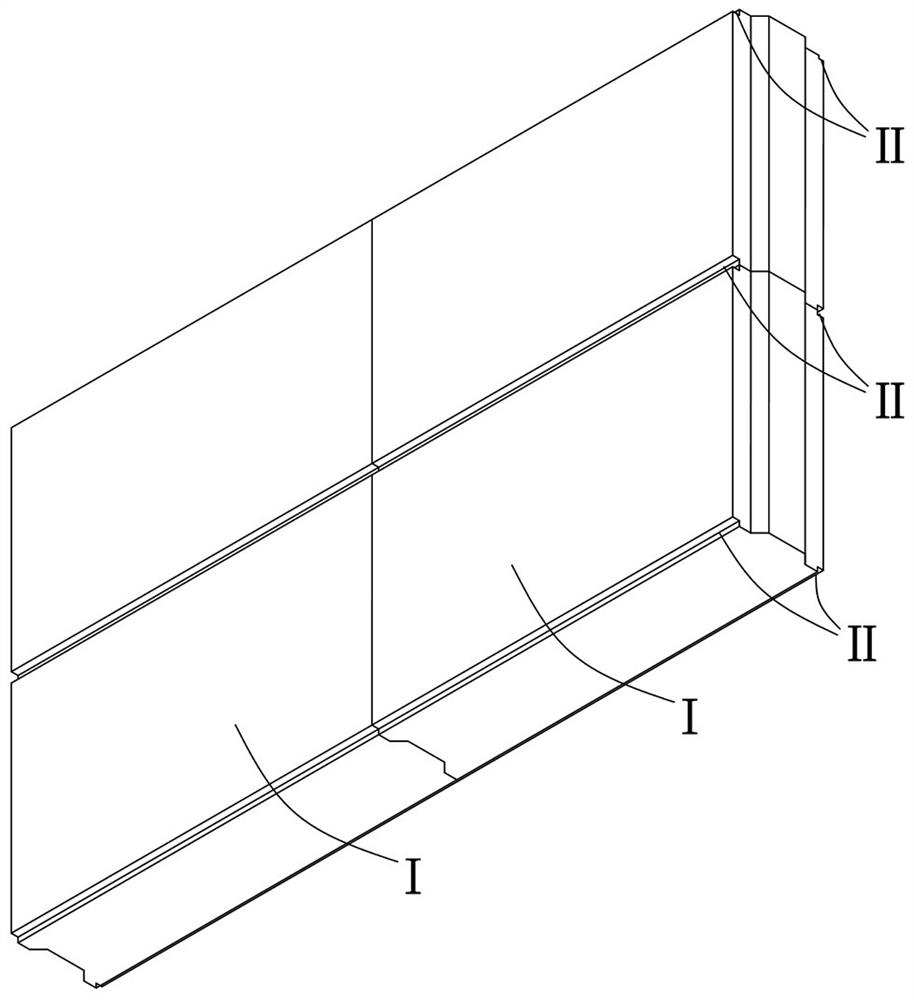

Grooving machine for processing anti-cracking grooves of steam pressurized concrete plate

A technology for concrete and grooving machines, which is applied to stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of increasing building construction costs and time costs, reducing building construction efficiency, and low labor efficiency, and achieving a reasonable structure. Reliable, low running inertia, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

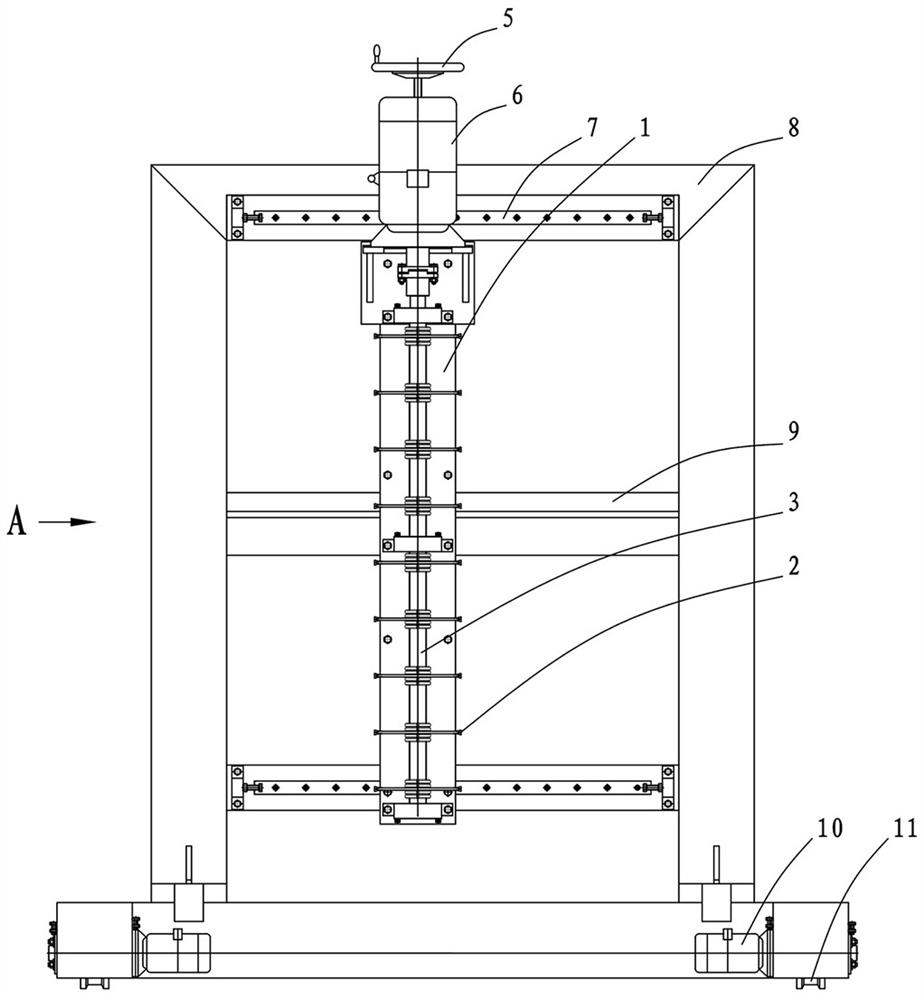

[0026] A grooving machine for processing steam-pressurized concrete slab anti-cracking grooves, comprising an underframe crane 8, a roller body 11 driven by a longitudinal movement drive device 10 is arranged on the lower part of the underframe crane 8, and The middle position place is provided with rack 9, and rack 9 is arranged parallel to the horizontal plane; Also be provided with slide rail 7, slide rail 7 is parallel with horizontal plane on the underframe driving 8 on the upper and lower sides of rack 9. The slide rail 7 is connected with the traversing frame 1 through a slider, and the traversing frame 1 is also provided with a traversing drive device 12 , the output shaft of the traversing drive device 12 is connected with a gear meshed with the rack 9 . The traversing frame 1 is connected to the adjustment frame body 14 by fastening bolts, the top of the overflow frame 1 is provided with a spindle fine-tuning screw 5 threaded with it, and the bottom end of the spindle...

Embodiment 2

[0028] A grooving machine for processing anti-cracking grooves of steam-pressurized concrete slabs, wherein the undercarriage 8 is also provided with a water pump 13, the water pump 13 is used to transport the water body to the universal water pipe through the pipeline, and the universal The water pipes are located around the circular saw blade 2 and the rotating spindle 3 . The structure and connection relationship of the remaining parts are the same as those described in any one of the foregoing embodiments, and will not be repeated here to avoid tedious writing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com