Changeable minisize multifunctional numerically-controlled machine tool

A CNC machine tool and multi-function technology, applied in the field of CNC machine tools, can solve the problems of not being able to move to the podium to explain demonstrations at any time, not being able to realize multiple uses of one machine, and the large size of CNC machine tools, so as to stimulate enthusiasm for learning, improve teaching effects, and function many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

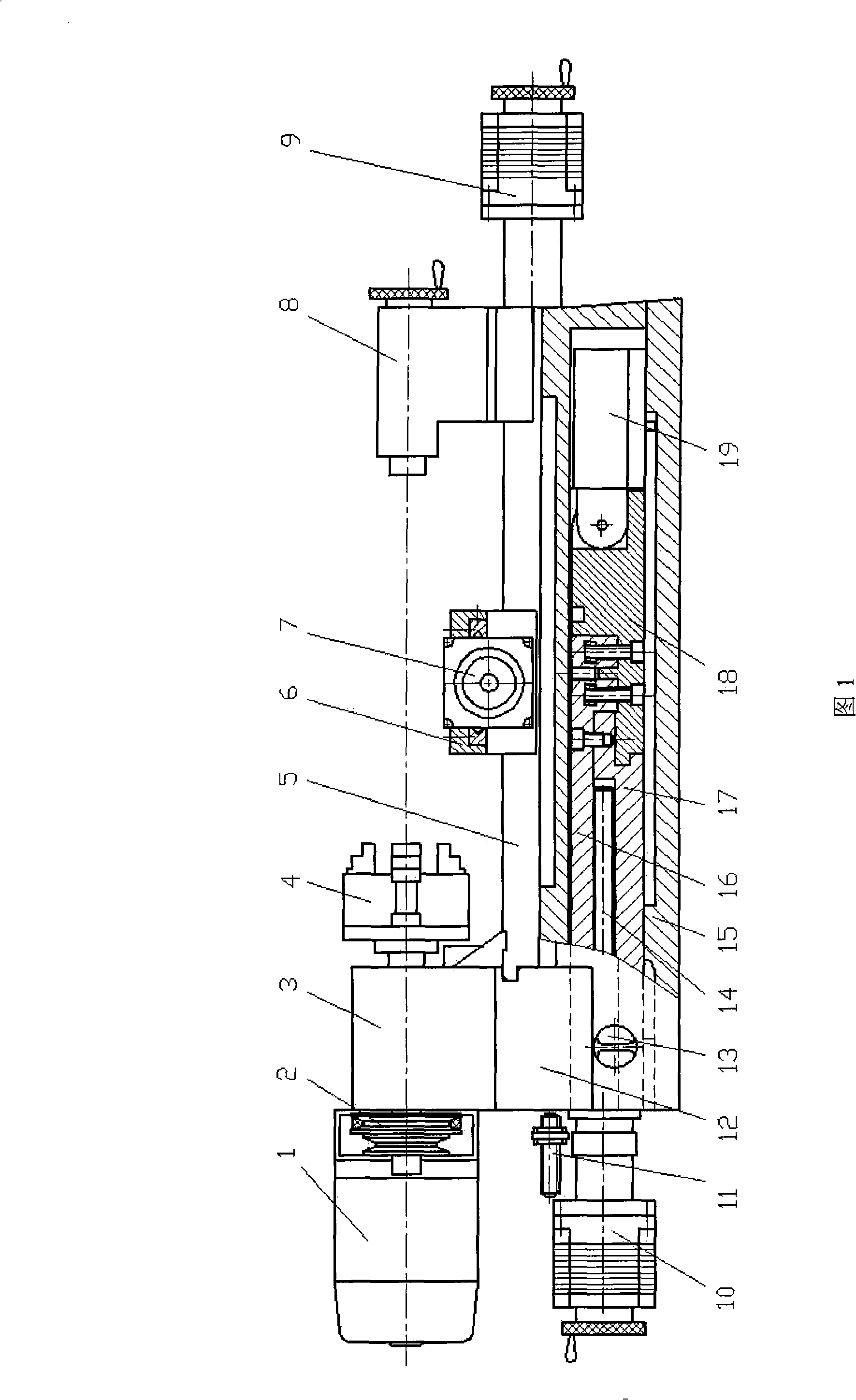

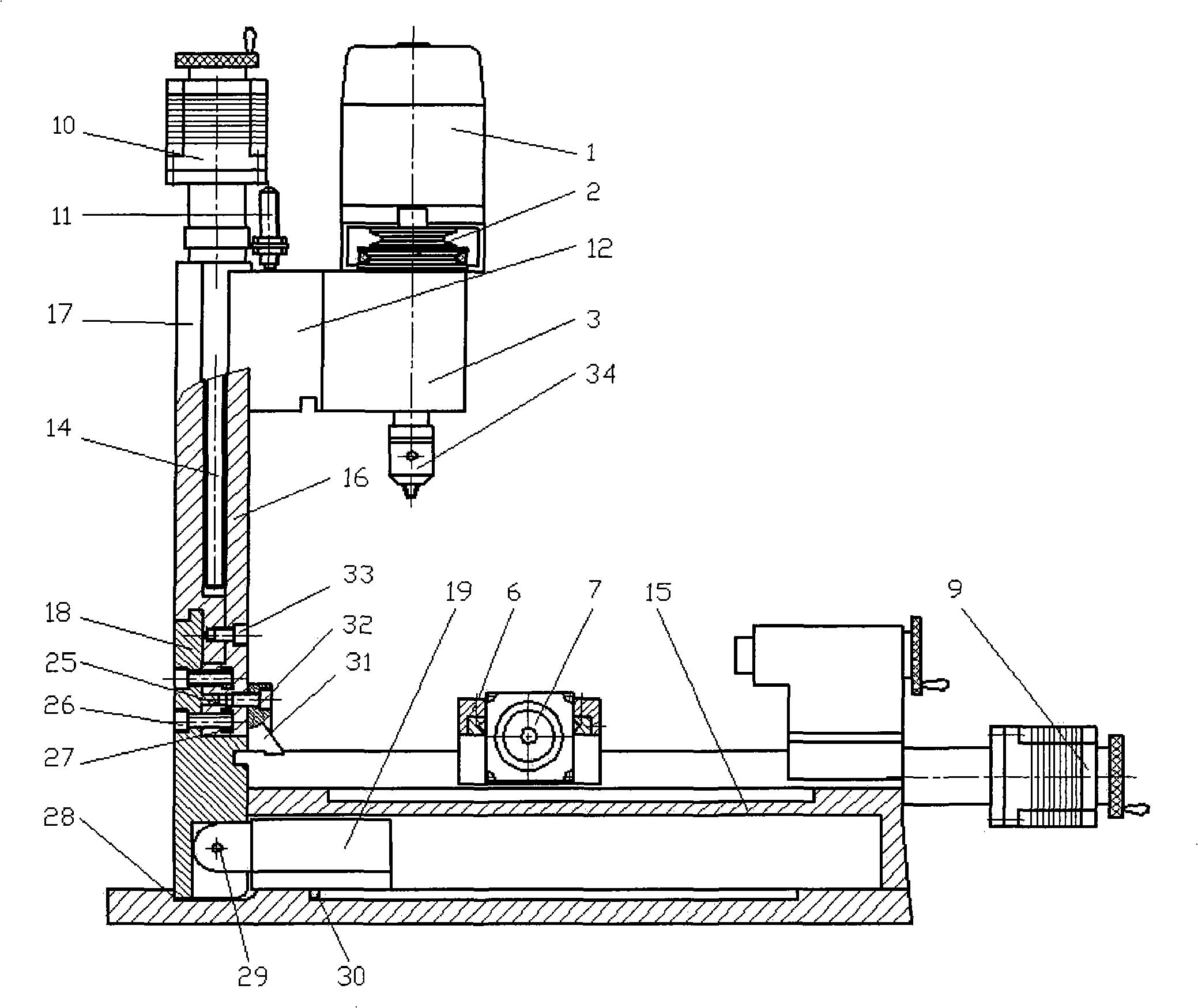

[0023] An indexable miniature multifunctional CNC machine tool, as shown in Figure 1, includes a horizontal bed 15, a bed guide rail 5, a saddle slide 6, a feed motor A7, a feed motor B9, and a bed guide rail 5. Fixed on the horizontal bed 15, the horizontal bed 15 is a hollow structure, the bed saddle slide 6 is located above the bed guide rail 5, and the feed motor B9 drives the bed saddle slide 6 to move longitudinally on the bed guide 5, by The feed electric 7 drives the saddle slide plate 6 to move laterally.

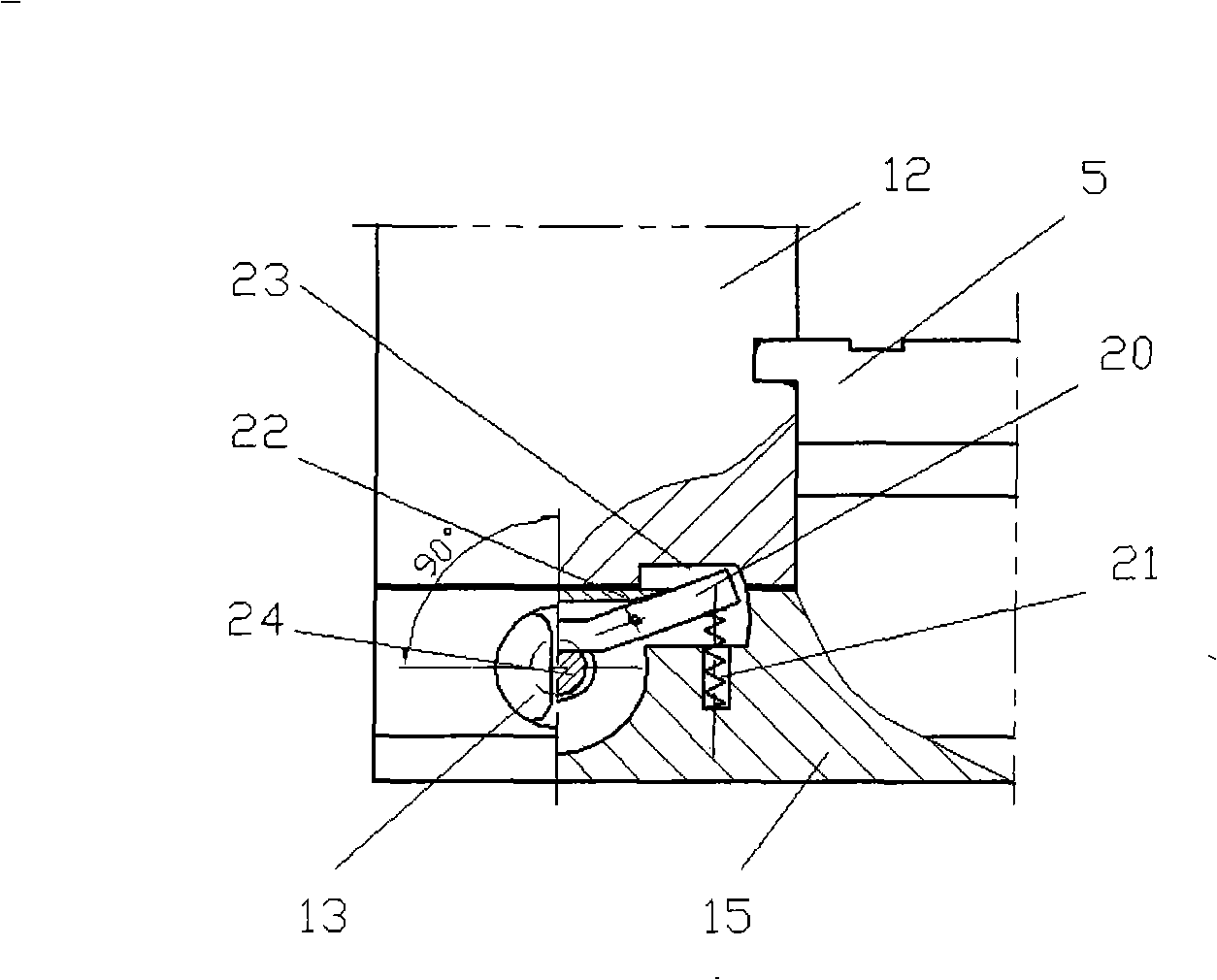

[0024] The conversion structure of micro-NC machine tool turning and milling, as shown in Figure 1, image 3 Shown, comprise spindle box 3, spindle box base 12, slide guide rail 16, slide column 17, circular turntable 18, limit guide slider 19, slide guide rail 16 is fixed on the slide column 17, spindle box 3 and The headstock b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com