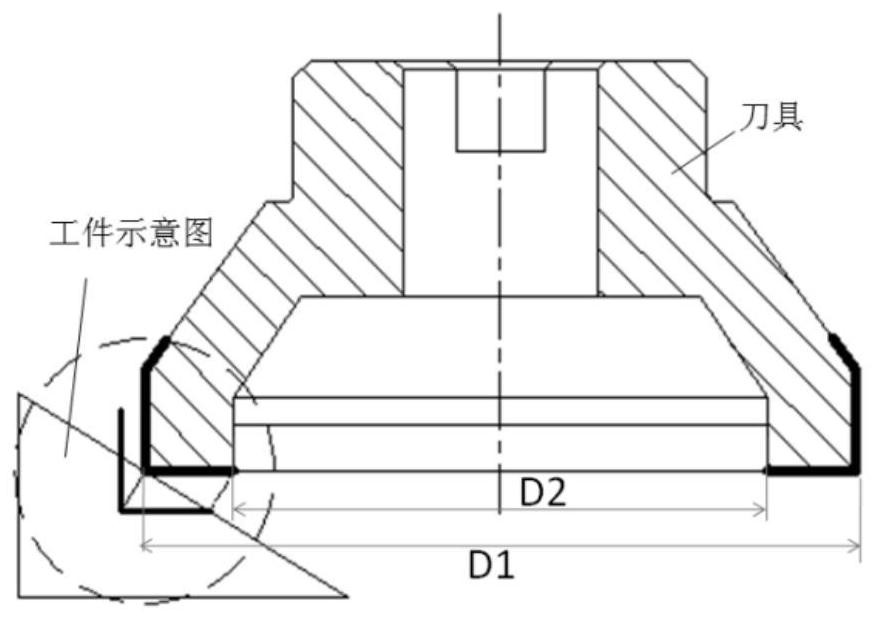

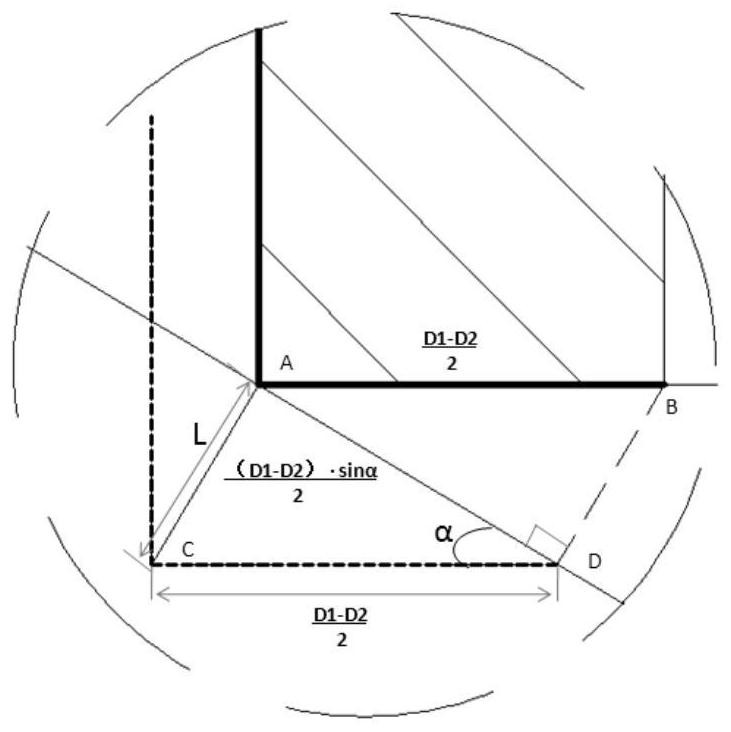

Disc-shaped milling cutter for multi-curvature curved surface efficient numerical control machining and application method thereof

A multi-curvature, processing disk technology, applied in milling cutters, metal processing, metal processing equipment and other directions, can solve problems such as tool wear and damage, reduce tool costs, ensure product processing accuracy, and solve the effect of serious tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

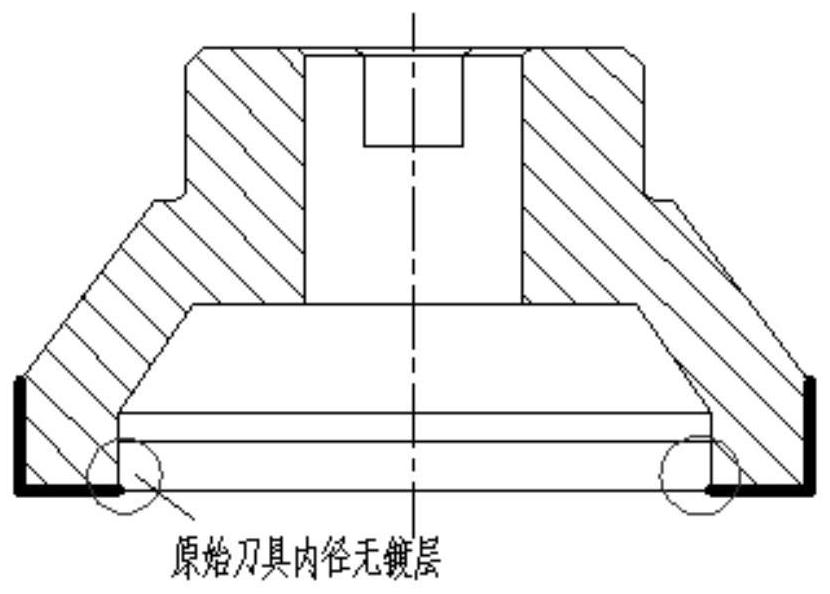

[0067] According to cutter structure of the present invention and design parameter design disc-shaped milling cutter, wherein the height of the sand coating on the inner wall surface of the second hollow column section is 5mm, and the projection of the sand coating area on the outer wall surface of the hollow cone section is 4mm in the vertical direction.

[0068] And follow the steps below to apply:

[0069] (1) Hoist the cabin to the machine table.

[0070] (2) According to the end face of the cabin body and the characteristics of the positioning pin, the clamping and alignment are established, and G54 is established;

[0071] (3) Install the P80 flat-bottom disc-shaped milling cutter and tighten it with screws. The tightening torque is required to be no less than 30N·M.

[0072] (4) Use a laser tool setting instrument to measure the total length of the disc milling cutter and the handle, the diameter of the tool, and the fillet at the end of the tool.

[0073] (5) Input t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com