Carbon nano-onion film-based supercapacitors for AC line filtering

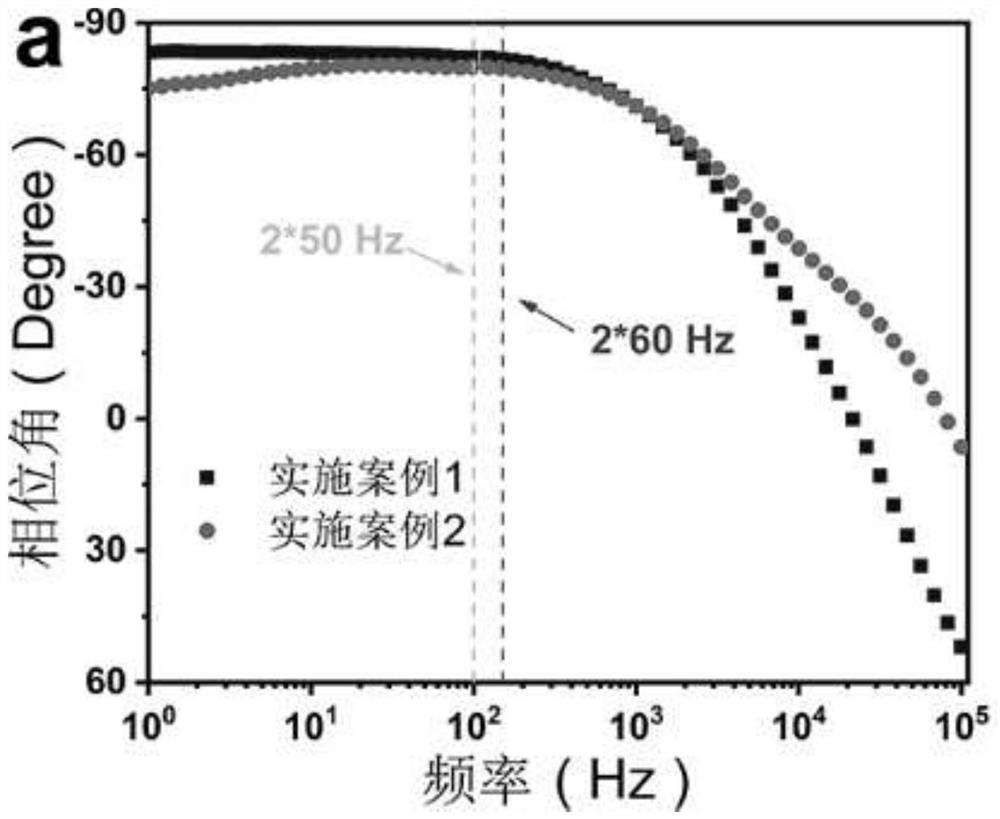

A carbon nano-onion and supercapacitor technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve the problems of low volume, complex preparation process, and low volume specific capacity of aluminum electrolytic capacitors, and achieve good AC filtering. The effect of performance, simple preparation process and high volume specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of carbon nano-onion film, comprising the following steps:

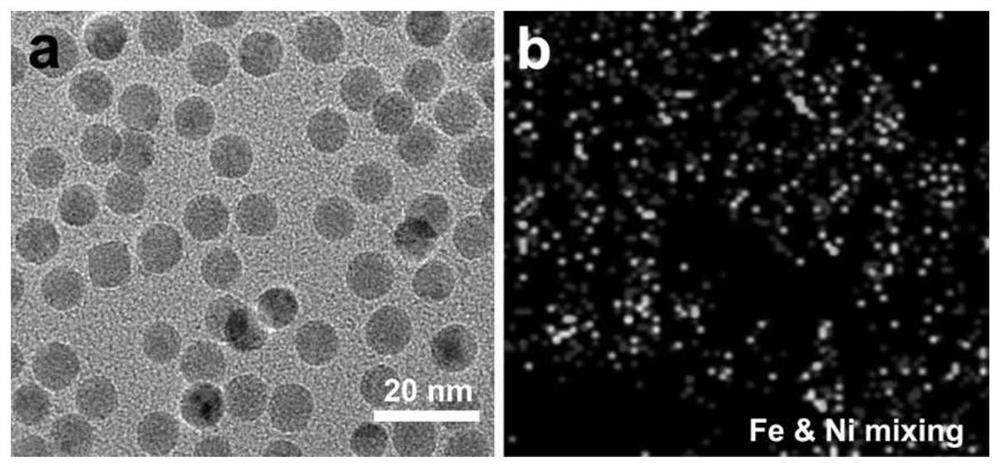

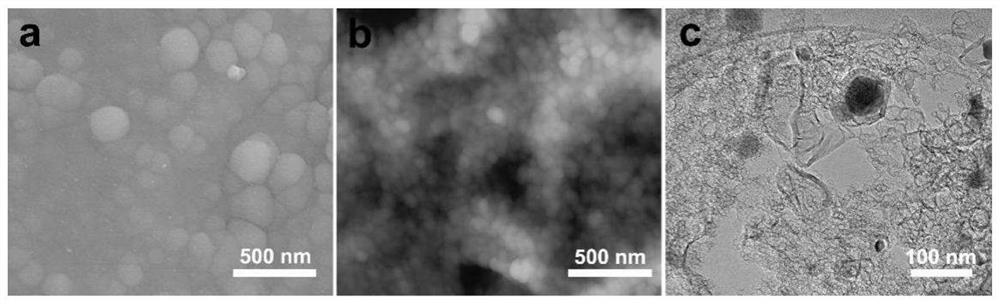

[0058] 1) Mix 0.541g of ferric chloride hexahydrate, nickel chloride hexahydrate and sodium oleate (providing oxidation function) as a solid, mix the solid with the first solution, heat at 60°C for 6 hours, add 40mL of deionized water Centrifuge to make the liquid layered, and then keep at 100°C for 1 hour to remove moisture to obtain a second solution, wherein the first solution is a mixture of absolute ethanol, deionized water and n-hexane, in parts by volume , the ratio of absolute ethanol, deionized water and n-hexane in the first solution is 1:1:2, and in parts by mass, the ratio of ferric chloride hexahydrate, nickel chloride hexahydrate and sodium oleate is 1: 1:4, the ratio of solid to first solution is 1:1.5 according to the amount of substance;

[0059] 2) Mix the second solution with 1-octadecene and oleic acid, in a nitrogen environment, keep the temperature at 120°C for 30 mi...

Embodiment 2

[0066] A preparation method of carbon nano-onion film, comprising the following steps:

[0067] 1) Mix 1.082g of ferric chloride hexahydrate, nickel chloride hexahydrate and sodium oleate (providing oxidation function) as a solid, mix the solid with the first solution, heat at 50°C for 4 hours, add 50mL of deionized water Centrifuge to make the liquid layered, and then keep at 100°C for 1.5 hours to remove moisture to obtain a second solution, wherein the first solution is a mixture of absolute ethanol, deionized water and n-hexane, in parts by volume , the ratio of absolute ethanol, deionized water and n-hexane in the first solution is 1:1:2, and in parts by mass, the ratio of ferric chloride hexahydrate, nickel chloride hexahydrate and sodium oleate is 2: 1:4, the ratio of solid to first solution is 1:2 according to the amount of substance;

[0068] 2) Mix the second solution with 1-octadecene and oleic acid, in a nitrogen environment, keep the temperature at 110 °C for 40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com