Photoluminescent material, application thereof, stress tracing material and ballistic gel

A technology of photoluminescent materials and tracer materials, which is applied in the direction of luminescent materials, ammunition, ammunition tests, etc., and can solve problems such as large background color interference, low marking accuracy, and complicated carrier attachment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation method of a kind of photoluminescence material of present embodiment, comprises:

[0056] S01. Pipette 2 mmol CsCl and 0.95 mmol InCl according to the preset stoichiometric ratio 3 and 0.05 mmol SbCl 3 ;

[0057] S02, at room temperature, CsCl, InCl 3 and SbCl 3 Grinding and mixing to obtain a photoluminescent material;

[0058] Wherein, the chemical composition of prepared photoluminescence material is as shown in formula (1):

[0059] 2CsCl 0.95InCl 3 0.05SbCl 3 (Formula 1)

[0060] Luminescence test

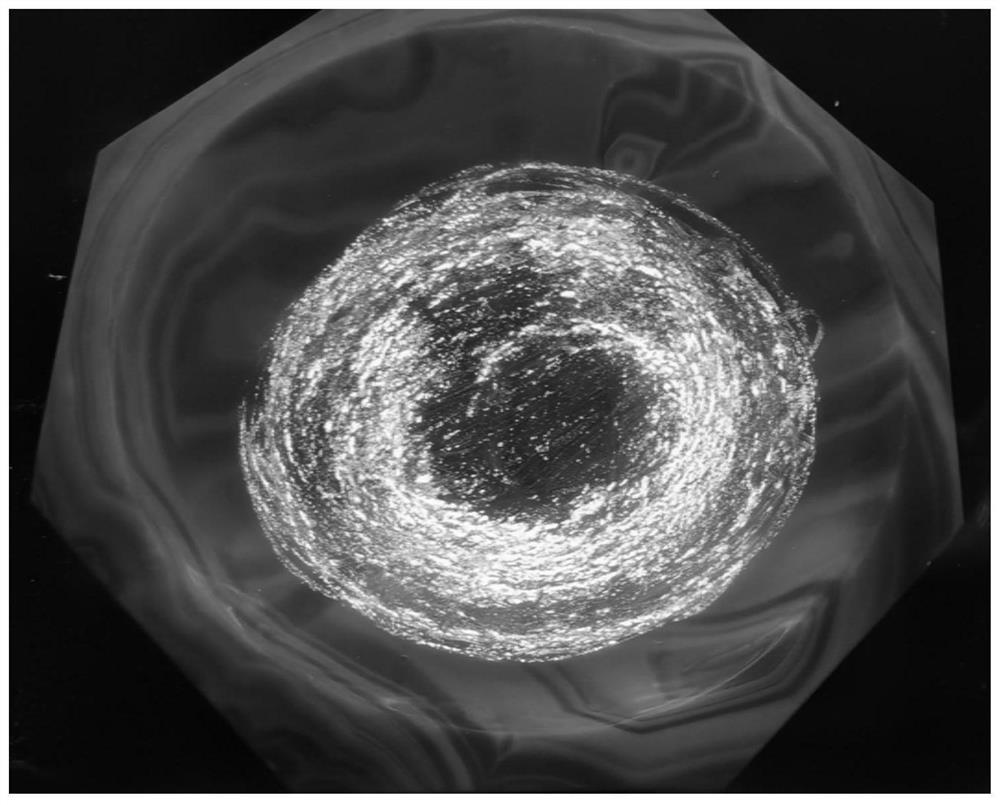

[0061] The photoluminescent material prepared in Example 1 was placed under an ultraviolet lamp for irradiation, and the photoluminescent material showed figure 1 Luminous state visible to the naked eye is shown.

[0062] based on figure 1 As shown in the characterization diagram, it can be deduced that the photoluminescent material prepared by this scheme has certain application potential in lighting, imaging, ink, photodetector, laser equip...

Embodiment 2

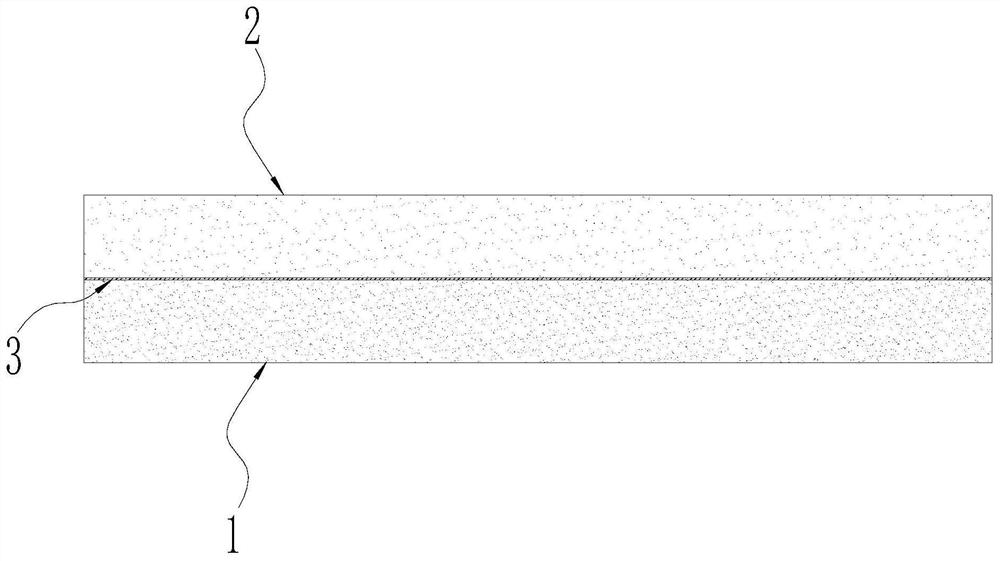

[0068] Such as figure 2 As shown, the present embodiment is a kind of stress tracer material, which comprises:

[0069] The first gel body 1, CsCl and InCl are dispersed in the first gel body 1 3 Dopant A formed by mixing;

[0070] The second gel body 2, the second gel body 2 is stacked with the first gel body 1, and SbCl is dispersed in the second gel body 2 3 dopant B formed;

[0071] Wherein, a buffer zone 3 with a preset thickness is formed on the lamination interface between the first gel and the second gel;

[0072] When the end face of the first gel body 1 away from the second gel body 2 receives a force greater than the first pressure, the dopant A in the first gel body 1 passes through the buffer zone and enters the The second gel body 2 is in pressure contact with the dopant B in the second gel body 2;

[0073] When the end face of the second gel body 2 away from the first gel body 1 receives a force greater than the first pressure, the dopant B in the second g...

Embodiment 3

[0084] Such as Figure 6 Shown, a kind of ballistic gel of the present embodiment, it comprises:

[0085] A number of first gel blocks 1, all of which have a rectangular structure, and CsCl and InCl are dispersed in the first gel blocks 1 3 dopant m formed by mixing;

[0086] A number of second gel blocks 2, all of which have a rectangular structure, and SbCl is dispersed in the second gel blocks 2 3 dopant n formed;

[0087] In this embodiment, the CsCl and InCl in the dopant m 3 with SbCl in dopant n 3 The molar ratio is 2:1.0:0.1.

[0088]Among them, several first gel blocks 1 and several second gel blocks 2 are colloidally arranged and the front and rear end surfaces are bonded sequentially; The buffer zone 11, 21 is formed with a preset thickness; the light transmittance of the first gel block 1 and the second gel block 2 body is not lower than 70%.

[0089] In addition, in this solution, the thickness of the buffer zone is 2mm. Since hydrogel usually has better wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com