Method for synthesizing ethylene glycol by using coke oven gas

A technology for coke oven gas and ethylene glycol, which is applied in chemical instruments and methods, removal of gas pollutants, preparation of organic compounds, etc. Great economic and social environmental benefits, the effect of making up for blast furnace heat loss and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

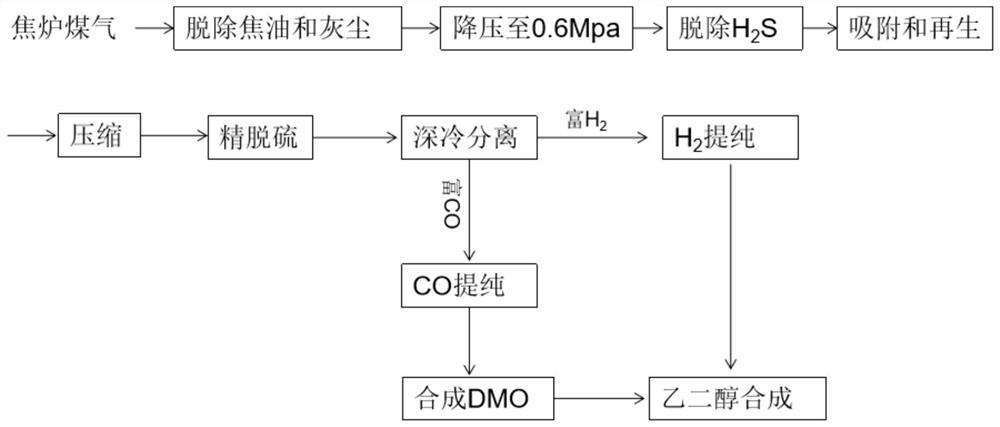

[0033] A method for synthesizing ethylene glycol with coke oven gas, comprising the following steps:

[0034] 1. The pressure sent from the coking plant is 5KPa and the flow rate is 120000Nm 3 / h The coke oven gas is sent to the FD type electric tar catcher to remove tar and dust;

[0035] 2. Send the coke oven gas after removing tar and dust to the screw compressor, and increase the pressure of the coke oven gas from 10Kpa to 0.6Mpa;

[0036] 3. Send the coke oven gas with a pressure of 0.6Mpa to the coke oven gas rough desulfurization tower to absorb and remove H in the gas 2 S, making H in the coke oven gas exiting the coke oven gas rough desulfurization tower 2 S content <1ppm;

[0037] 4. Send the coke oven gas from the coke oven gas rough desulfurization tower in step 3 into the TSA adsorption tower for adsorption and regeneration, and transfer to the regeneration process after the TSA tower absorbs tar, naphthalene, benzene, ammonia, HCN and a small amount of sulfur ...

Embodiment 2

[0052] With the isolated H 2 76% analytical gas (the composition of the analytical gas is as shown in Table 1) is used for blast furnace injection ironmaking

[0053] Table 1 Analysis gas composition

[0054] Element H 2

CH 4

CO CO 2

N 2

h 2 o

Total content / % 76 12.5 1.5 1 9 0 100

[0055] 1. Will contain H 2 The desorption gas with a volume of 76% is pressurized to 0.80Mpa by a pressurizer;

[0056] 2. The analytic gas pressurized to 0.80Mpa is sent to the high-temperature multi-tube heat exchanger through the gas delivery pipeline with a diameter of DN500, and is heated in sections under the action of the high-temperature flue gas of 1100°C generated by the flue gas generator. Heating it to 750°C in the same way (normal temperature → 250°C → 500°C → 750°C);

[0057] 3. Send the analytical gas heated in step 2 into the cracking furnace, and use 2417Nm 3 / h Supplement oxygen for combustion, thereby adjusting the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com