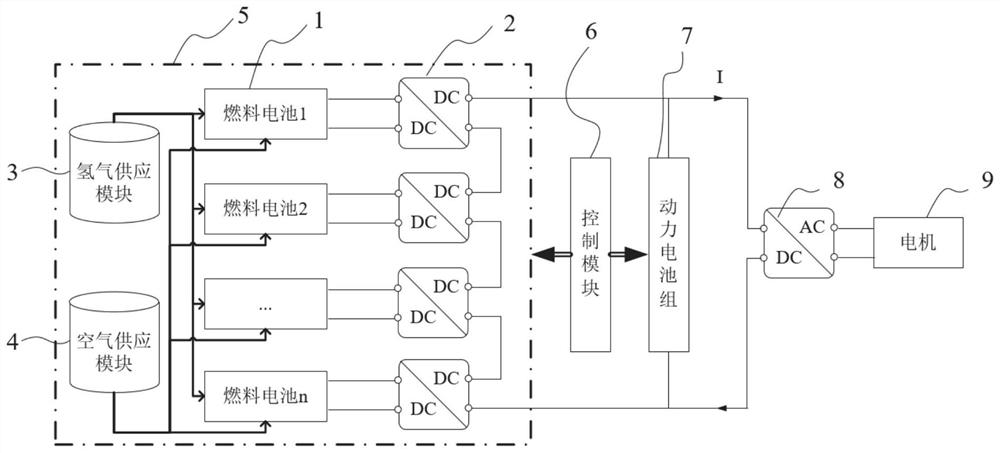

Electric vehicle power system based on multi-stack fuel cells

A fuel cell system and electric vehicle technology, applied in electric vehicles, battery/fuel cell control devices, battery/battery traction, etc., can solve the problems of high cost and high DCDC requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

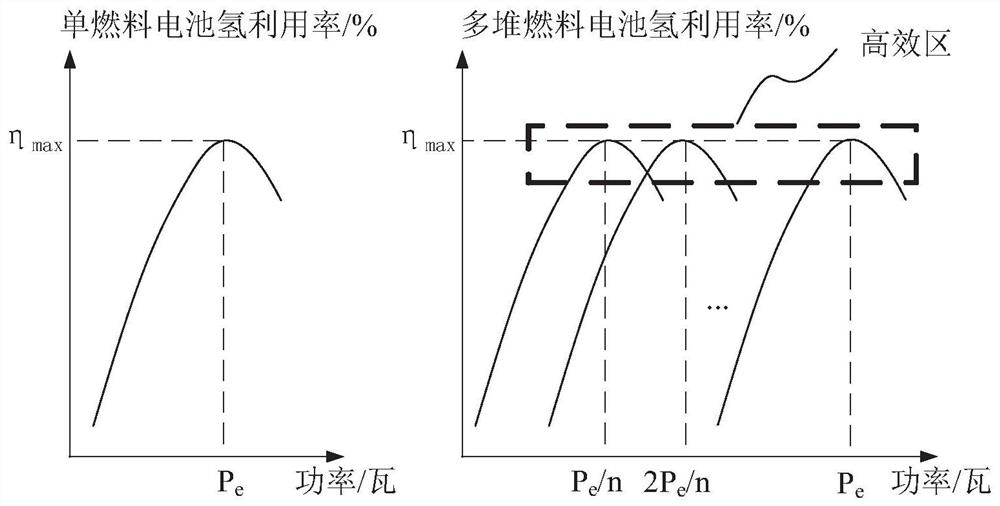

Problems solved by technology

Method used

Image

Examples

Embodiment approach

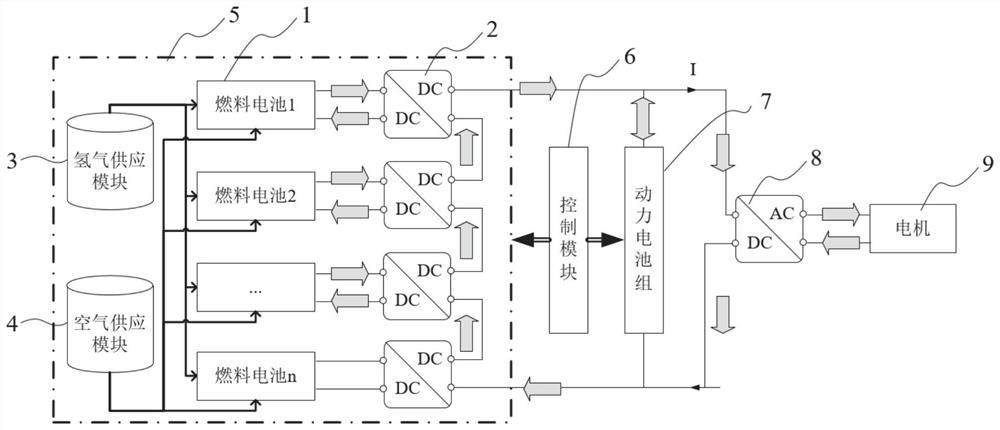

[0041]In this embodiment, the size, shape, rated power and number of fuel cell stacks 1 in the multi-stack fuel cell system 5 are determined according to actual load requirements and application scenarios. The power design methods of the fuel cell stack include: power equal distribution, Daisy chain distribution and power optimization distribution. The power battery pack 7 is connected in parallel with the multi-stack fuel cell subsystems 5 through wires, and the type, size, shape and rated capacity of the power battery pack 7 are determined according to the actual application scenario. The power design methods of the power battery pack 7 include: allocation based on rules, allocation based on optimization and allocation based on learning. As an implementation manner, the power battery pack 7 may choose to use a lithium titanate battery pack.

[0042] In this embodiment, the control module 6 can adopt STM32F103 high-speed embedded single-chip microcomputer.

[0043] The mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com