Online laser marking device and method for hot-rolled steel billet

A technology of laser marking and billet, applied in the field of billet continuous casting and rolling, laser marking, and iron and steel production, it can solve the problems of expensive high temperature resistant paint, ineffective marking and erasing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

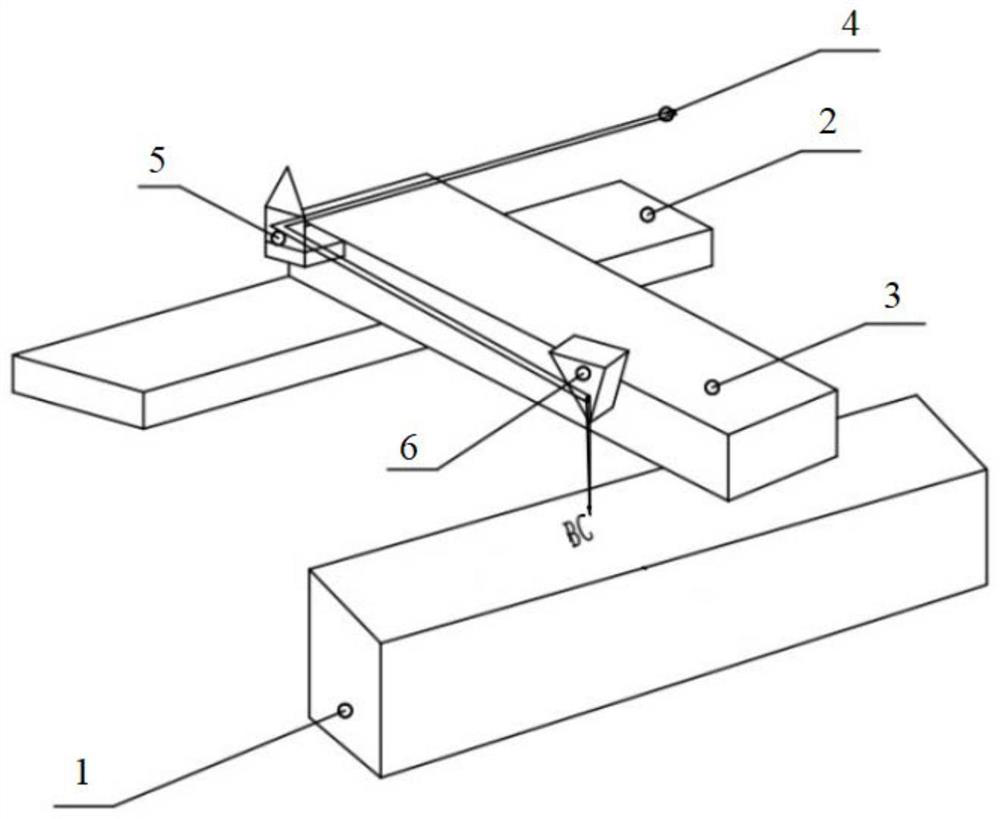

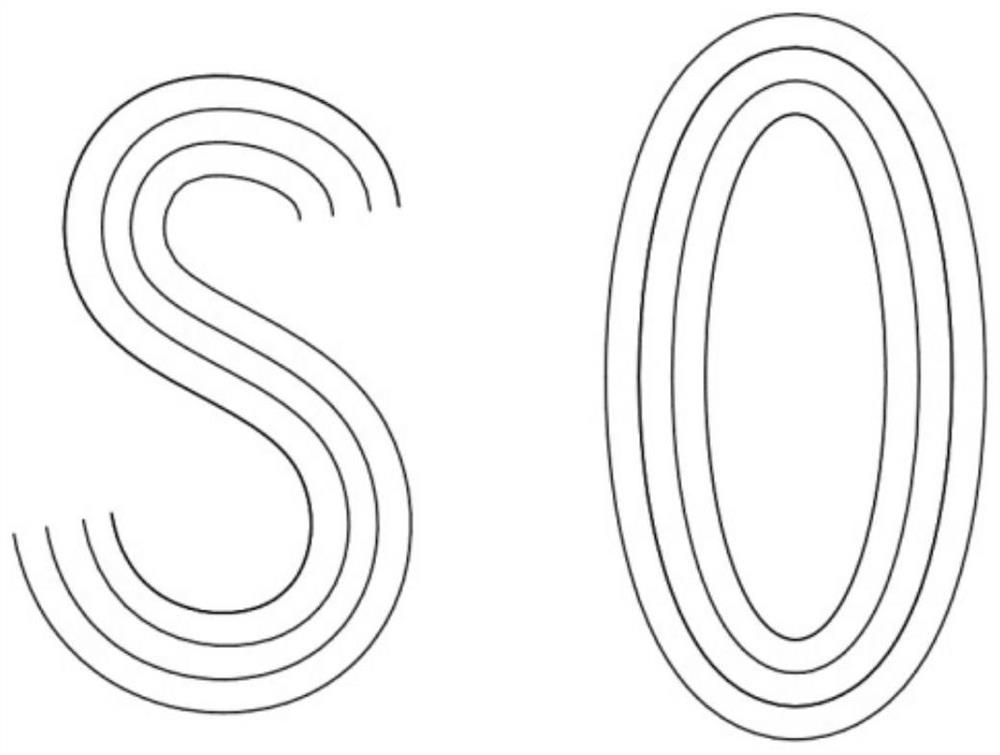

[0046] This embodiment provides a hot-rolled billet online laser marking device and method, such as figure 1 As shown, the device is set above the hot-rolled steel billet production line, and can perform laser marking on the hot-rolled billet 1 online. The device includes: a laser, a light guide mechanism, a focusing mechanism, a two-dimensional linear motion mechanism and a control unit. The two-dimensional linear motion mechanism includes a Y guide rail 2 and an X guide rail 3, wherein the X guide rail 3 is installed on the Y guide rail 2, and the two are arranged perpendicularly, and the X guide rail can move along the Y direction with the Y guide rail 2, The light guiding mechanism and the focusing mechanism are installed on the X guide rail 3, and can move with it under the drive of the two-dimensional linear motion mechanism, wherein the light guiding mechanism is used to guide the irradiation direction of the laser beam 4 emitted by the laser, and the focusing mechanism ...

Embodiment 2

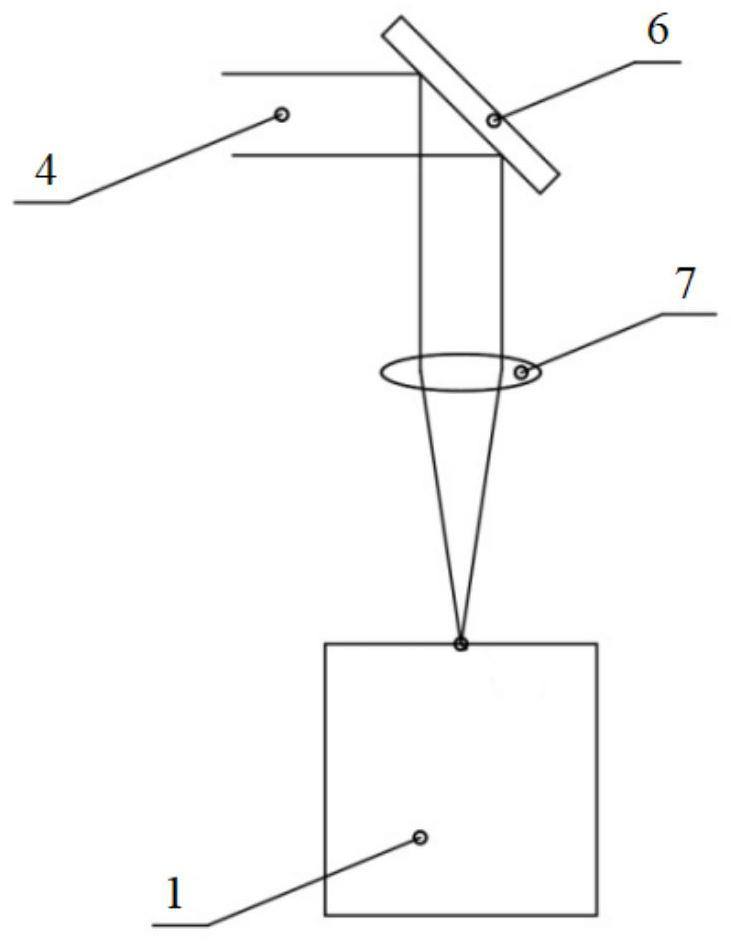

[0071] This embodiment provides a hot-rolled billet online laser marking device and method, such as Figure 7 As shown, the device is set above the hot-rolled steel billet production line, and can perform laser marking on the hot-rolled billet 1 online. The device includes: a laser, a light guide mechanism, a focusing mechanism, a two-dimensional linear motion mechanism and a control unit. The two-dimensional linear motion mechanism includes a Y guide rail 2 and an X guide rail 3, wherein the X guide rail 3 is installed on the Y guide rail 2, and the two are arranged perpendicularly, and the X guide rail can move along the Y direction with the Y guide rail 2, The light guiding mechanism and the focusing mechanism are installed on the X guide rail 3, and can move with it under the drive of the two-dimensional linear motion mechanism, wherein the light guiding mechanism is used to guide the incident direction of the laser beam 4 emitted by the laser, and the focusing mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com