Static blasting construction method of hydraulic splitter

A static blasting and splitting machine technology, which is applied in the fields of discharge machinery, construction, building maintenance, etc., can solve the problems of affecting the splitting effect, unable to erect drilling equipment, and increasing the difficulty of crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

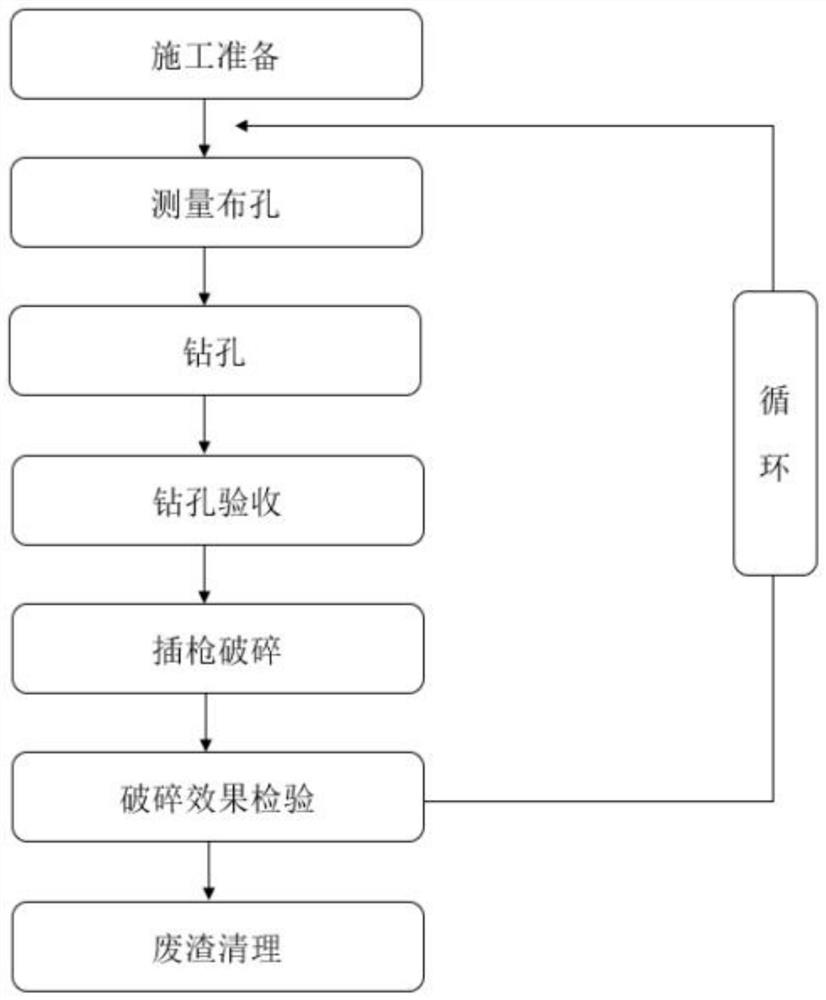

[0070] Hydraulic splitting machine static blasting construction method, such as figure 1 shown, including the following steps:

[0071] Step 1: Construction preparation

[0072] (1) According to the actual situation of the construction site, set up isolation belts and arrange warning lines to prevent nearby personnel and vehicles from entering the construction area by mistake and affecting the construction;

[0073] (2) Retighten all equipment screws before starting the equipment;

[0074] (3) Before starting the air compressor, pay attention to whether the temperature of the motor is normal, whether the readings of the electric meters are within the specified range, whether the operating sound of each part is normal, whether the suction valve cover is hot, and whether the sound of the suction valve is normal. Whether all kinds of safety protection equipment are reliable, check whether the moving parts are flexible, whether the connecting parts are fastened, whether the lubr...

Embodiment 2

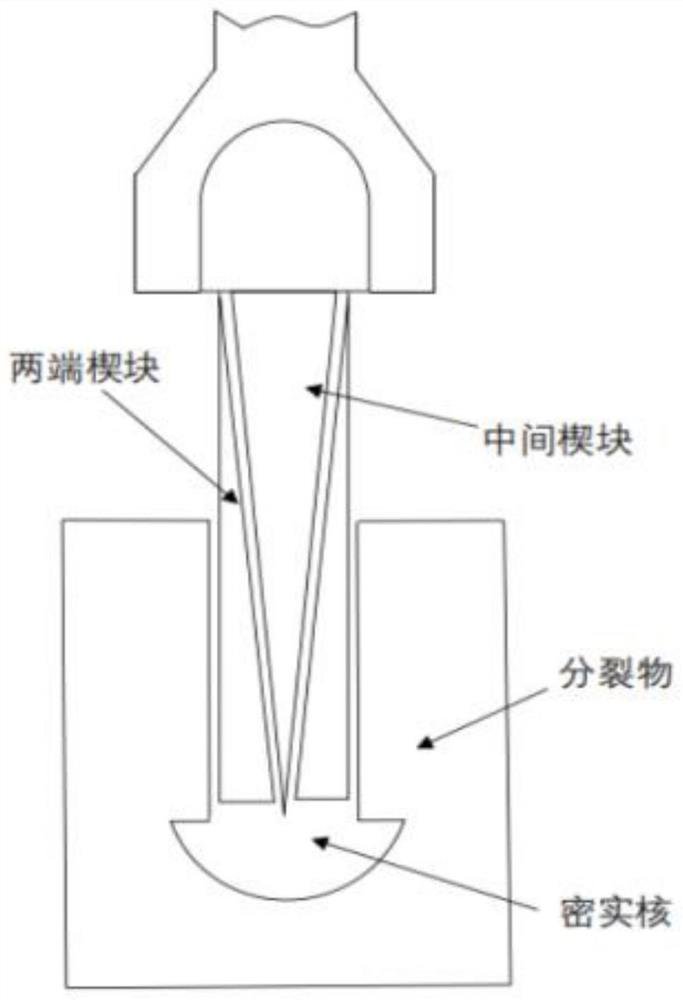

[0124] Any object has its own characteristics, rocks and concrete have extremely high external compressive strength, but the tensile strength from the inside to the outside is very small, and its compressive strength and tensile strength have a ratio of 100: (2-10) difference. The splitting machine is designed by grasping the brittle characteristics of rock and concrete, and cleverly utilizing the wedge principle-"a great splitting force can be released outward in the narrowest hole".

[0125] The working principle of the splitting machine: figure 2 As shown, the wedges at both ends are attached to the middle wedge to form a 42mm cylinder-splitter. Drill a number of 42mm holes on the predetermined rock splitting line in advance, then insert the splitter into these holes, start the pump station to supply ultra-high pressure hydraulic oil to the splitting gun, when the hydraulic splitting After passing through the high-pressure oil, the machine can generate thrust in the abov...

Embodiment 3

[0127] Dangerous rock removal project for Weilihe Bridge Pier No. 6 in Wucan section of Lanzhou-Haikou Expressway on G75 line. Dangerous rocks are fracturing beams and columns. The surrounding environment is complex. There are residential areas 100m away from dangerous rocks. Mechanical crushing and traditional blasting cannot be implemented. Under the circumstances, the "static blasting construction technology of hydraulic splitting machine" is used to carry out directional crushing of dangerous rocks, so that there is no secondary hazard, which ensures the construction quality and safety, shortens the construction period, reduces the project cost, and has been awarded by the superior Leaders and local residents alike.

[0128] The static blasting construction technology of the hydraulic splitter has excellent performance in dangerous rock removal, stone mining and various emergency rescue and disaster relief. It also has significant economic and social benefits. It has wide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com