Waterproof plugging structure for roof pipeline and construction method

A construction method and roof structure layer technology, applied in the direction of roof, roof covering layer, building structure, etc., can solve the problems of affecting the roof waterproof effect, peeling of coiled materials, rainwater infiltration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

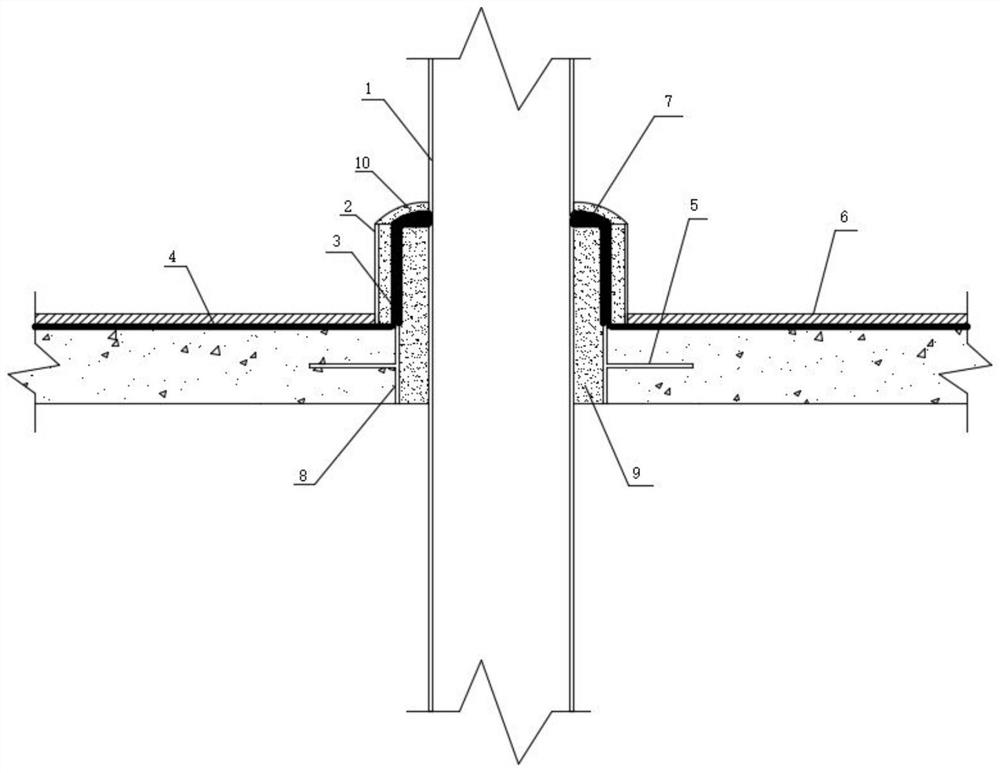

[0025] Such as figure 1 As shown, a waterproof sealing structure for the roof outlet pipeline includes a steel sleeve 8 (set coaxially with the roof outlet pipeline 1) embedded in the roof structure layer and equipped with a water stop ring 5, poured on the steel sleeve 8 and the polymer waterproof mortar between the roof pipe 1-9, the leveling layer 4 above the roof structure layer, the waterproof coiled material 3 bonded to the upper surface of the leveling layer 4 and the outside of the steel sleeve 8, sealed in the The waterproof membrane 3 and the asphalt-based sealant 7 on the top of the polymer waterproof mortar are set on the outer side of the waterproof membrane 3 and the galvanized pipe 2 with a gap between the inner wall and the waterproof membrane 3 is reserved, and poured on the galvanized pipe 2 and waterproof Polymer waterproof mortar 2 10 between the rolls 3 and covering the top of the asphalt-based sealant 7 . The waterproof coiled material 3 is protected by ...

Embodiment 2

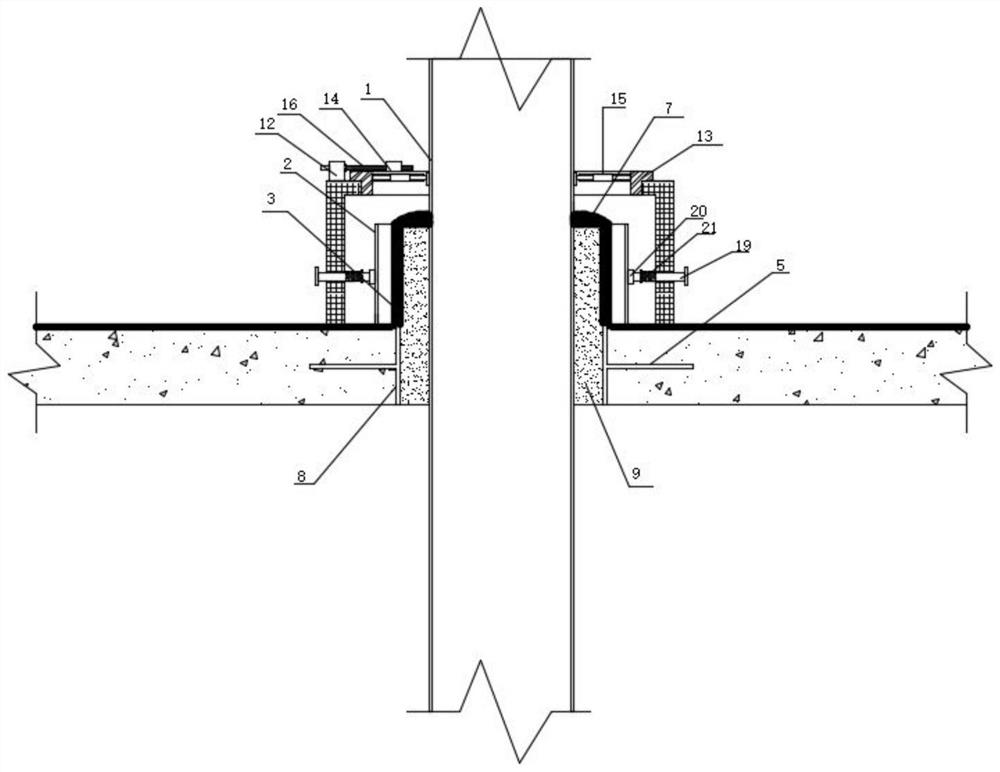

[0028] Embodiment 2: as figure 2 and image 3 As shown, a further preferred solution on the basis of Embodiment 2: the construction method of the above-mentioned embodiment includes the following steps: first, the steel casing 8 is pre-embedded inside the roof structure layer, and the roof pipe 1 is installed and located at the bottom of the roof structure layer. formwork at the bottom of the slab, spread mortar on the surface of the roof structure layer as a leveling layer 4, and spread and bond waterproof membrane 3 on the leveling layer 4, and wrap the steel casing 8 and turn it over by the top of the steel casing 8 Wrap the top of the steel casing 8, then pour polymer waterproof mortar-9 between the roof outlet pipe 1 and the steel casing 8, and then cover the top of the polymer waterproof mortar-9 and the waterproof membrane 3 for asphalt-based sealing Paste 7, set galvanized pipe 2 on the outside of steel casing 8, and pour polymer waterproof mortar 2 10 between galvan...

Embodiment 3

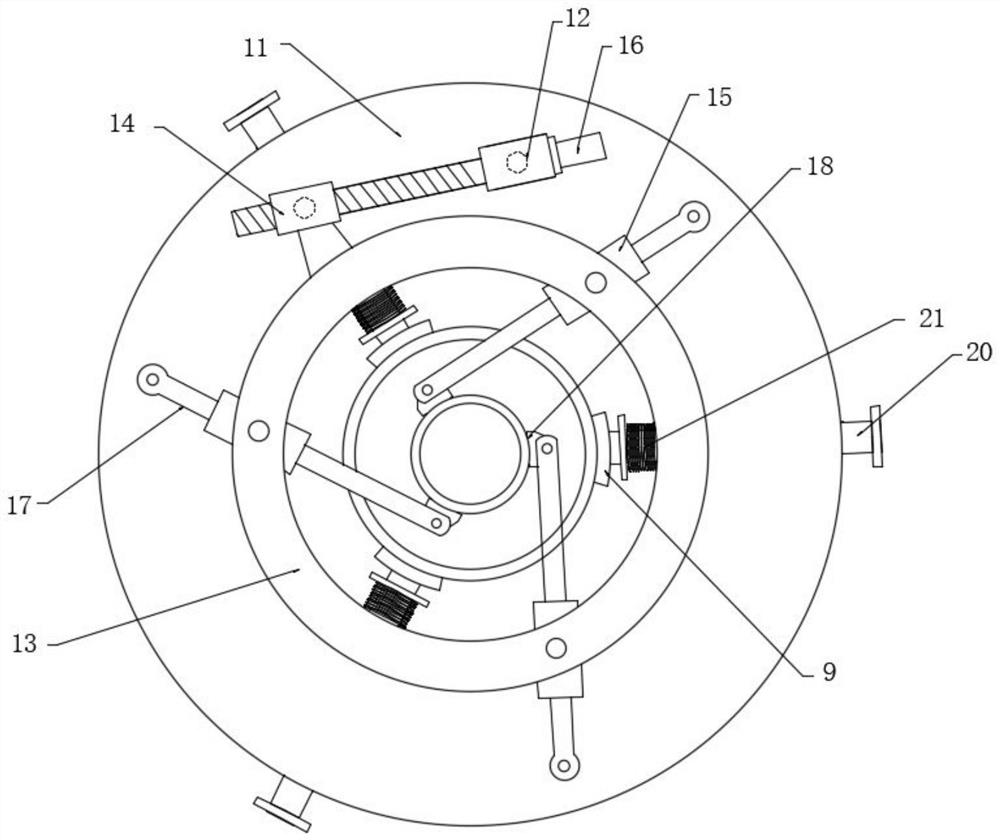

[0033] Embodiment 3: as figure 2 and image 3 As shown, a further preferred solution on the basis of Example 2: the installation of the galvanized pipe 2 and the working steps of pouring the polymer waterproof mortar 2 10 are as follows:

[0034] First place the galvanized pipe 2 on the outside of the steel casing 8, then install the mounting frame 11 on the outside of the galvanized pipe 2, and clamp the galvanized pipe 2 through the positioning claw 20, and then adjust the rotation by adjusting the adjusting screw 16 The positions of the seat one and the rotating seat two drive the active part 13 to rotate relative to the mounting frame 11, and the rotating seat will rotate accordingly, and the position of the driven part 17 will also change with the rotation, and the jaws 18 on the driven part 17 will automatically rotate. Clamp the roof outlet pipe 1, at this time, the galvanized pipe 2 is automatically coaxial with the roof outlet pipe 1 and the steel casing 8, pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com