Preparation method of nano gradient magnesium alloy

A magnesium alloy and gradient technology, applied in the field of high-strength magnesium alloy preparation, can solve the problem that the fine-grain strengthening potential of magnesium alloy cannot be fully reflected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

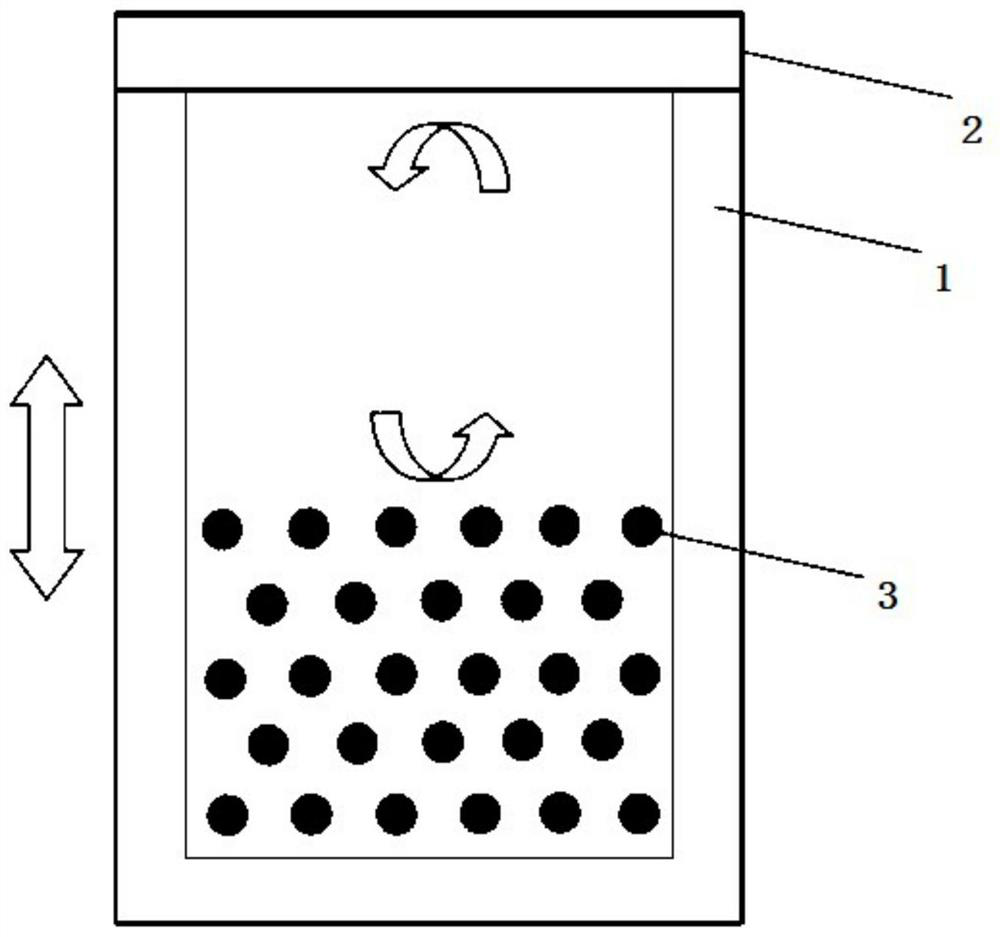

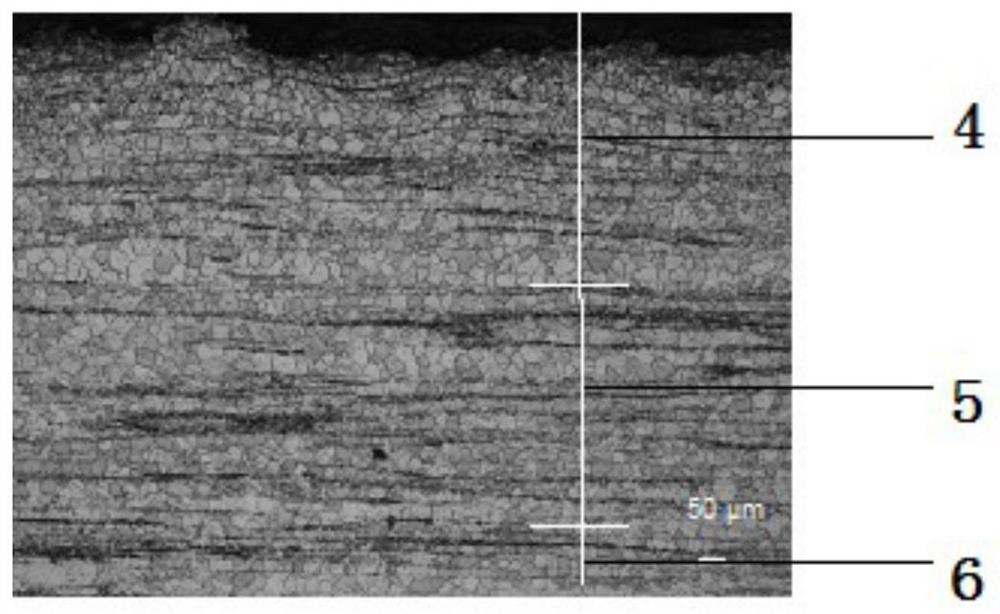

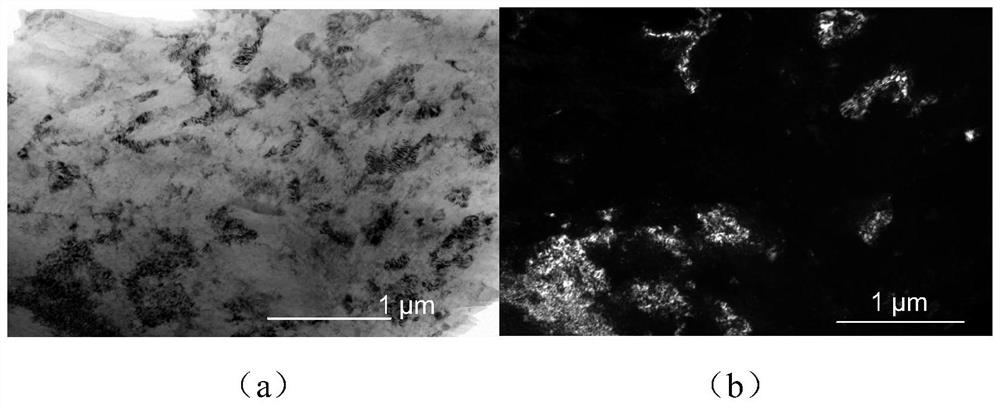

[0027] Attached below Figure 1-3 The specific embodiment of the present invention is described in detail with embodiment, but the present invention should not be limited to embodiment.

[0028] A kind of preparation method of nano-gradient magnesium alloy of the present embodiment, preparation method comprises the following steps:

[0029] Step 1: adopt semi-continuous casting method to prepare magnesium alloy ingot, its magnesium alloy mass percentage composition is as follows:

[0030] Gd: 8.0-9.5; Y: 2.0-3.5; Zr: 0.3-0.7; the balance is Mg.

[0031] Step 2: Homogenize the magnesium alloy ingot.

[0032] Step 3: Squeeze and deform the homogenized billet, specifically: homogenize the semi-continuously cast magnesium alloy ingot and extrude it into a bar to form an extruded alloy. The extrusion temperature is 4350°C. The extrusion ratio is 15:1.

[0033] Step 4: Perform peak aging treatment on the extruded alloy, that is, keep it at 225° C. for 18 hours.

[0034] Step 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com