A nanocellulose/glass fiber/immobilized nanosilver durable antibacterial filter material and its preparation method and application

A technology of nano-cellulose and glass fiber, which is applied in the field of filtration, can solve the problems of weak binding force between nano-silver and the filter material substrate, excessive release, and easy leakage, etc., which is conducive to large-scale industrial production, meets demand, and has low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

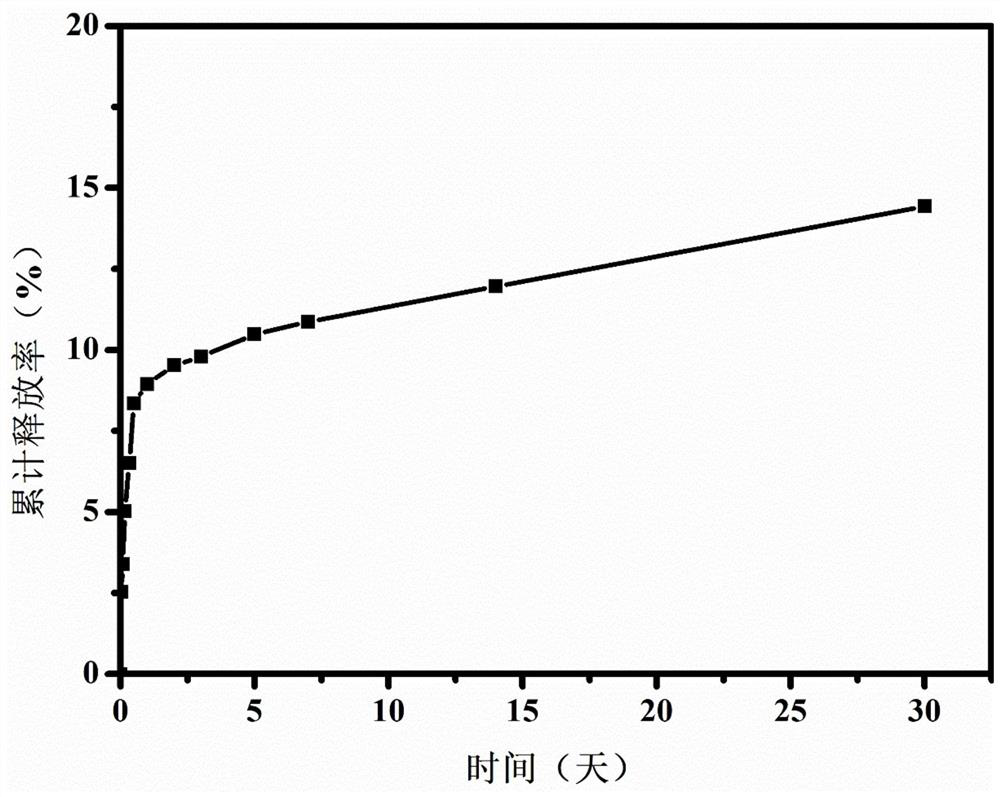

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of a nanocellulose glass fiber durable antibacterial filter material, the specific steps are as follows:

[0038] (1) The hectorite (diameter 25nm) solution with a concentration of 0.1 g / L was prepared, and 5 mL of silver ammonia solution with a concentration of 0.001 mol / L was added to 40 mL of hectorite solution under stirring, and the mixture was uniform to obtain hectorite- Silver ammonia mixed solution;

[0039](2) in the hectorite-silver ammonia mixed solution obtained in step (1), adding the alkali lignin solution with a concentration of 1 g / L to obtain a reaction solution, the volume of the alkali lignin solution being 10% of the volume of the reaction solution %, carry out the reduction reaction, the reaction temperature is 50 ℃, and the reaction is carried out for 30 minutes to obtain the hectorite-immobilized nano-silver composite antibacterial agent, which is for subsequent use;

[0040] (3) Disperse glass fibers (fiber diameter 0.5 μm), nan...

Embodiment 2

[0044] The preparation of a nanocellulose glass fiber durable antibacterial filter material, the specific steps are as follows:

[0045] (1) The hectorite (diameter 25nm) solution with a concentration of 1 g / L was prepared, and 5 mL of silver ammonia solution with a concentration of 0.1 mol / L was added to 40 mL of hectorite solution under stirring, and the mixture was uniform to obtain hectorite-silver Ammonia mixed solution;

[0046] (2) in the hectorite-silver ammonia mixed solution obtained in step (1), adding the alkali lignin solution with a concentration of 2g / L to obtain a reaction solution, the volume of the alkali lignin solution being 10% of the volume of the reaction solution %, carry out the reduction reaction, the reaction temperature is 60 ℃, and the reaction is carried out for 60 minutes to obtain the hectorite-immobilized nano-silver composite antibacterial agent, which is for subsequent use;

[0047] (3) Disperse glass fibers (fiber diameter 1 μm), nanocellul...

Embodiment 3

[0051] The preparation of a nanocellulose glass fiber durable antibacterial filter material, the specific steps are as follows:

[0052] (1) The hectorite (diameter 25nm) solution with a concentration of 6g / L was prepared, and 5mL of hectorite solution with a concentration of 1mol / L was added to 40mL of hectorite solution under stirring, and mixed well to obtain hectorite-silver ammonia mixture;

[0053] (2) in the hectorite-silver ammonia mixed solution obtained in step (1), add the alkali lignin solution that concentration is 5g / L, obtain reaction solution, and the volume of described alkali lignin solution is 10% of the volume of reaction solution %, carry out the reduction reaction, the reaction temperature is 80 ℃, and the reaction is carried out for 90 minutes to obtain the hectorite-immobilized nano-silver composite antibacterial agent, which is for subsequent use;

[0054] (3) Disperse glass fibers (fiber diameter of 5 μm), nanocellulose (fiber average diameter of 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com