Device for producing ammonium sulfate through neutralization and crystallization of caprolactam redischarge liquid and ammonia, and application of device

A technology of caprolactam and ammonium sulfate is applied in the field of producing ammonium sulfate by reacting sulfuric acid and ammonia, which can solve the problems of large cooling water and spray water, not meeting the production needs of large-scale chemical plants, and not conforming to the concept of green environmental protection development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Caprolactam rearrangement liquid and ammonia neutralization crystallization unit, the production capacity of ammonium sulfate is 150,000 tons / year.

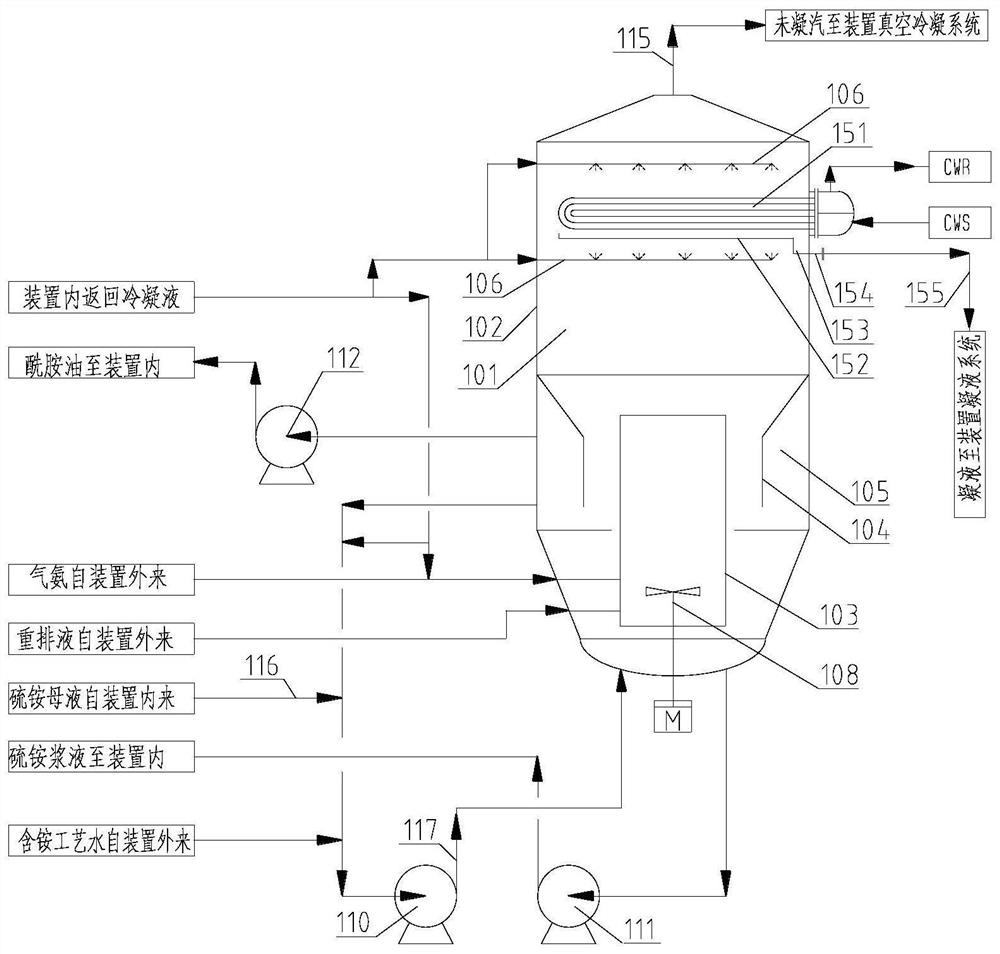

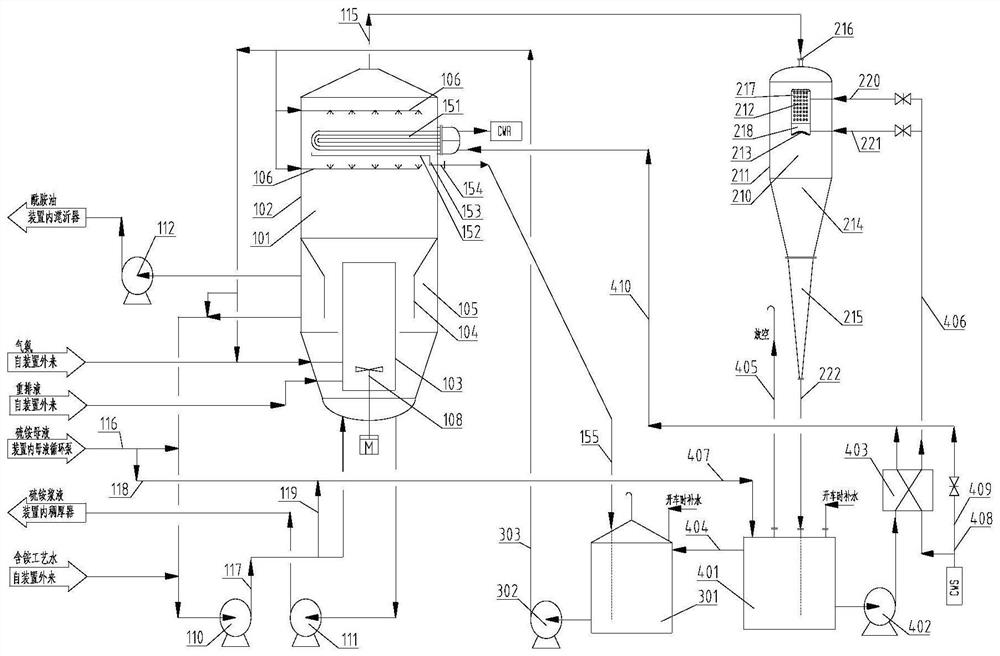

[0078] A built-in main condenser (151) is installed inside the DTB neutralization crystallizer (101), and a jet vacuum tail condensation system (200), condensate system (300), etc. are set outside the neutralization crystallizer body (101); jet vacuum Tail condensing system (200) adopts jet vacuum condenser (210), supporting jet liquid system (400), and the technological process is as attached figure 2 .

[0079] Ammonia gas and rearrangement liquid from outside the device are added by ratio adjustment, ammonia gas is dissolved and absorbed into ammonia water by the condensate liquid from the condensate return pipe (303), and ammonia water and rearrangement liquid enter the DTB neutralization crystallizer through their respective nozzles (101); under the action of the draft tube (103) and the stirrer (108), an internal c...

Embodiment 2

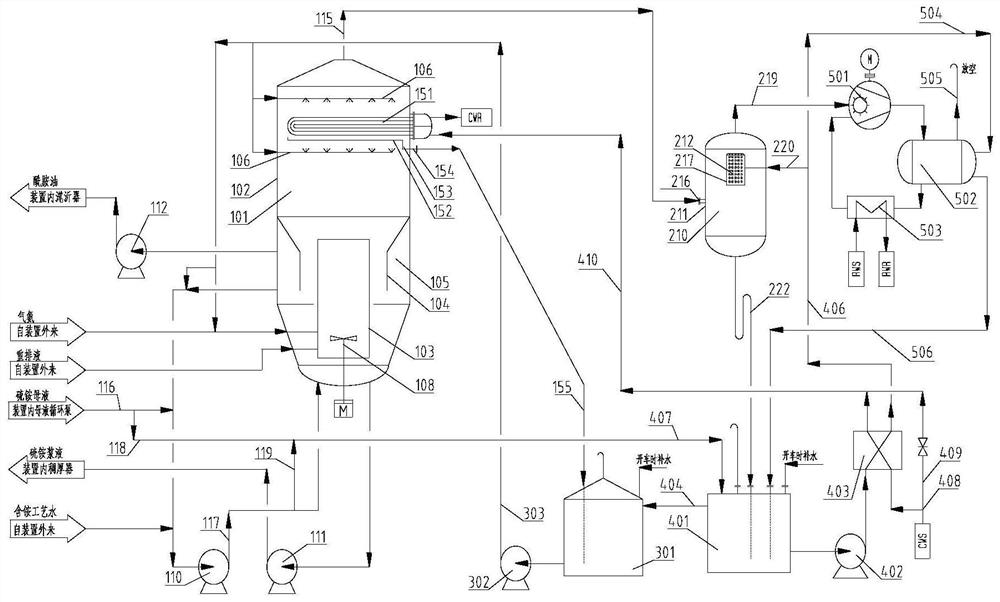

[0089] Caprolactam rearrangement liquid and ammonia neutralization crystallization unit, the production capacity of ammonium sulfate is 150,000 tons / year.

[0090] A built-in main condenser (151) is arranged inside the DTB neutralization crystallizer (101), and a jet tail condensation system (200), a condensate system (300), etc. are arranged outside the neutralization crystallizer body (101); the jet tail condensation The system (200) adopts a jet condenser (210) and a supporting jet liquid system (400); the vacuum facility is set up independently, and a liquid ring vacuum system (500) is adopted, and the technological process is as attached image 3 .

[0091]Ammonia gas and rearrangement liquid from outside the device are added by adjusting the ratio. The ammonia gas is dissolved and absorbed into ammonia water by the condensate sent by the condensate return pipe (303). The ammonia water and rearrangement liquid enter the DTB through their respective nozzles for neutralizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com