A high-efficiency air tritiated water vapor condensation collection device in the field

A collection device, water vapor technology, applied in the direction of sampling device, steam condensation, climate sustainability, etc., can solve the problems of difficult to guarantee the source of liquid nitrogen, small amount of water vapor collection, unfavorable water vapor condensation, etc., to facilitate regular disassembly and cleaning and maintenance, beneficial to cleaning and maintenance, and convenient to collect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

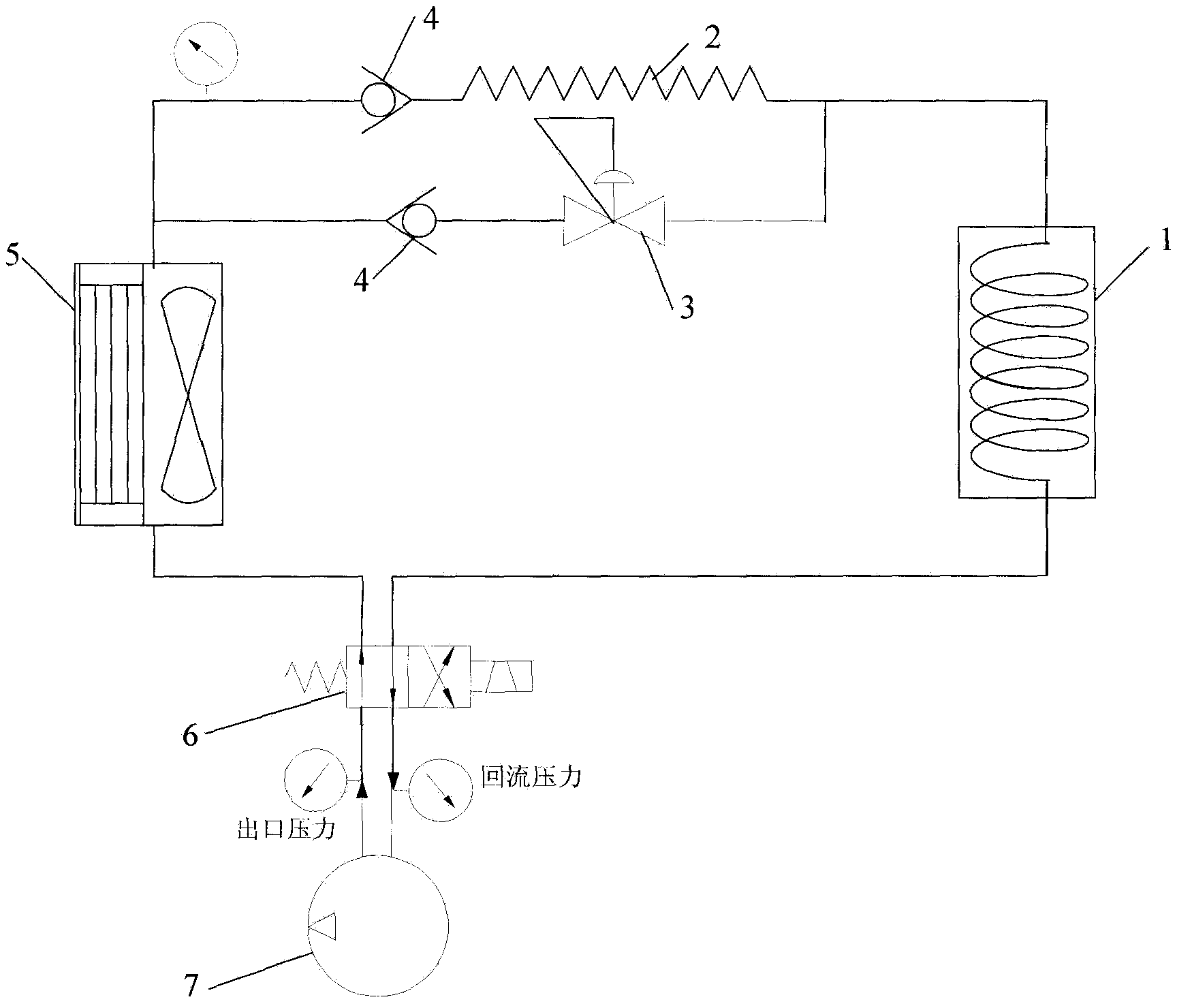

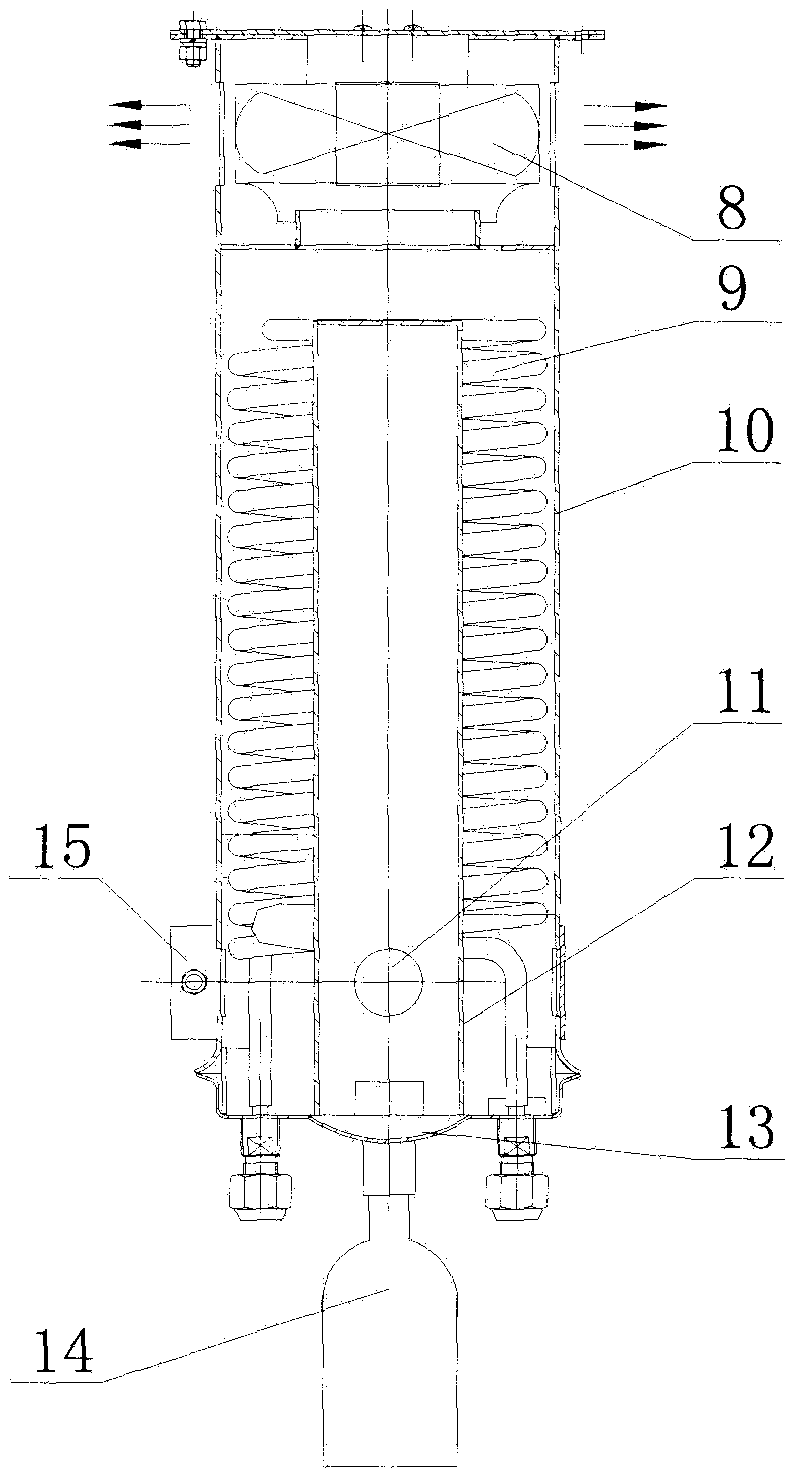

[0018] Such as figure 1 Shown is the composition and working principle diagram of the collection device of the present invention, including an evaporator assembly 1, a capillary tube 2, a thermal expansion valve 3, a one-way valve 4, a condenser 5, an electromagnetic reversing valve 6 and a compressor 7. figure 2 It is a schematic structural diagram of the evaporator assembly 1, including a fan 8, a spiral finned tube 9, an outer cylinder 10, an air inlet 11, a central cylinder 12, a water collecting bucket 13, and a collecting bottle 14.

[0019] Such as figure 2 As shown, the spiral-finned tube 9 is coiled on the outer surface of the central cylinder 12, the spiral-finned tube 9 and the central cylinder 12 are sleeved together inside the outer cylinder 10, the fan 8 is located at the top of the outer cylinder 10, and the air inlet 11 is arranged on the outer cylinder 10 The outer surface of the outer cylinder body 10 is equipped with a water collection bucket 13, the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com