High-stability inorganic sulfide solid electrolyte and preparation method thereof

An inorganic sulfide and electrolyte layer technology, applied in the field of lithium-ion batteries, can solve the problems of reduced structural ionic conductivity, restrictions on the application of all-solid-state lithium batteries, and instability of inorganic sulfide electrolytes, and achieves a simple and effective preparation method, good air Stability, air stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

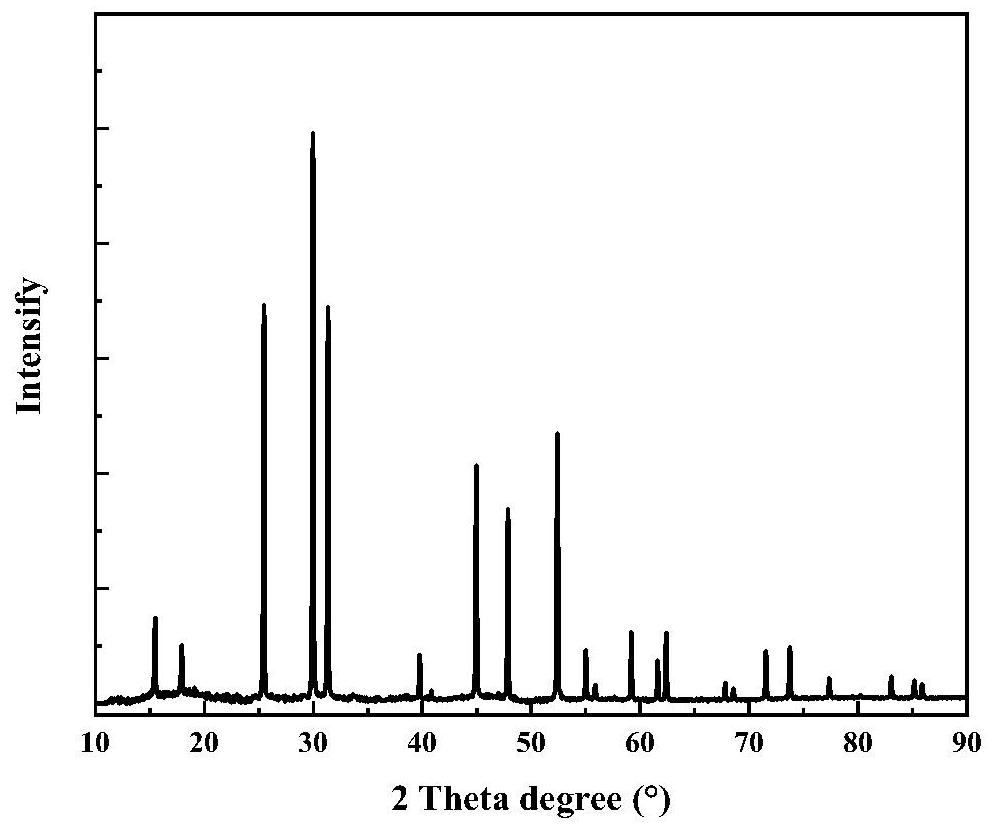

Embodiment 1

[0043] In a glove box, according to Li 6.1 P 0.9 SN 0.1 S 4.9 O 0.1 Cl elements in the proportions of Li weighed 2 S, p 2 S 5 , LiCl, SnS 2 , Li 2 O, each of the above material is placed in a zirconia ball mill jar 50ml, was added 50g of 5mm diameter zirconia beads. The sealed mill pot placed on a ball mill, the set rotational speed of 400 rpm, milling 12h. After milling the sample was collected and sealed in a vacuum quartz tube calcined. Temperature-programmed calcination temperature controlled, heated from room temperature to 550 deg.] C over 100min, and held at this temperature for 16h, then cooled to control 4h 50 ℃, Li can be obtained 6.1 P 0.9 SN 0.1 S 4.9 O 0.1 Cl solid electrolyte material.

Embodiment 2~11

[0045] Except in accordance with Li 7+a-c (P 1-a M ' a ) (S 6-b-c M " b ) X c The proportion of the elements weighed Li 2 S, p 2 S 5 , M'S 2 , Li 2 M ", LiX, the other when the same synthesis conditions in Example 1. Note that, depending on the composition, the heat treatment temperature and time are different.

Embodiment 12

[0047] In a glove box, according to Li 5.6 P 0.9 SN 0.1 S 4.4 Se 0.1 CL 1.5 The proportion of the elements weighed Li 2 S, p 2 S 5 , LiCl, SnS 2 , Li 2 Se, each of the above material is placed in a zirconia ball mill jar 50ml, was added 50g of 5mm diameter zirconia beads. The sealed mill pot placed on a ball mill, the set rotational speed of 400 rpm, milling 10h. After milling the sample was collected and sealed in a vacuum quartz tube calcined. Temperature-programmed calcination temperature controlled, heated from room temperature to 480 deg.] C over 100min, and held at this temperature for 8h, then cooled to control 4h 50 ℃, Li can be obtained 5.6 P 0.9 SN 0.1 S 4.4 Se 0.1 CL 1.5 The solid electrolyte material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com