Quantum dot complex, three-dimensional display element and processing method of quantum dot complex

A processing method and quantum dot technology, which is applied to electrical components, semiconductor devices, circuits, etc., can solve the problems of low vertical resolution, low brightness, and single viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

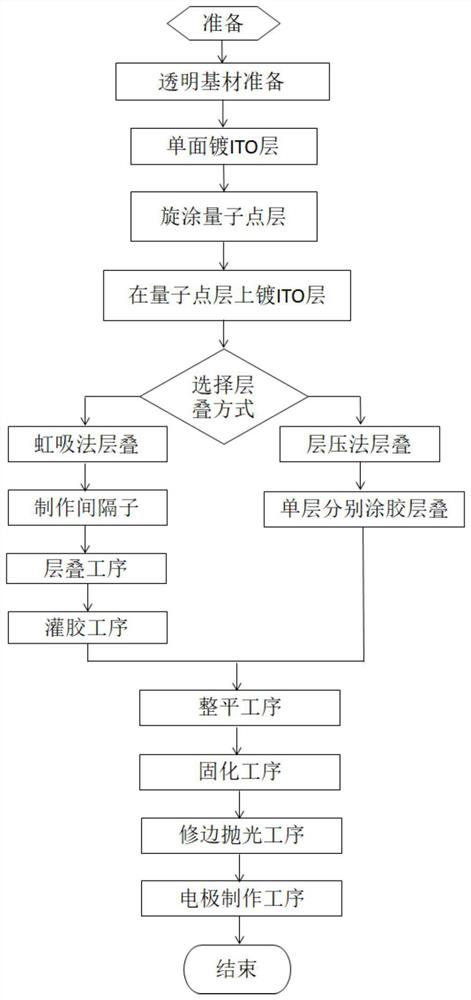

[0115] Embodiment 1: making quantum dot complex 100 by siphon method

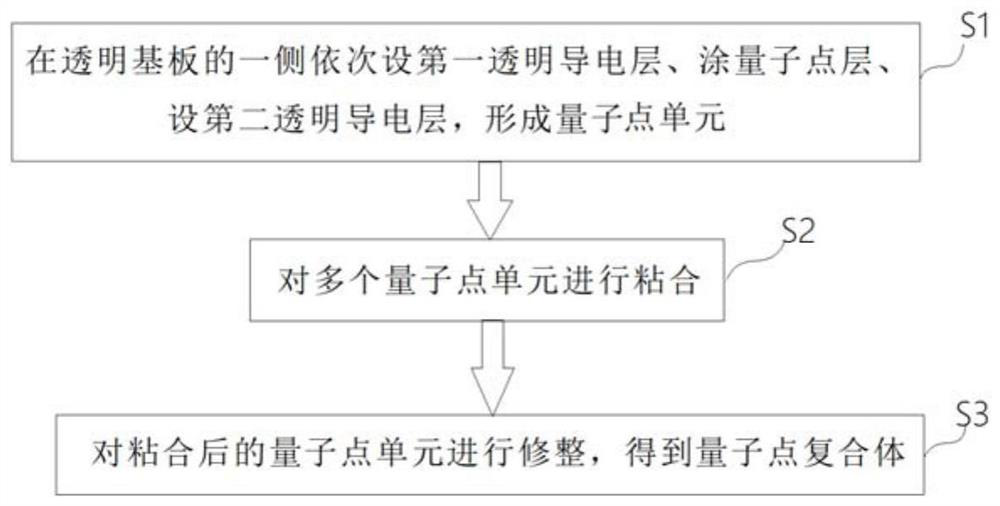

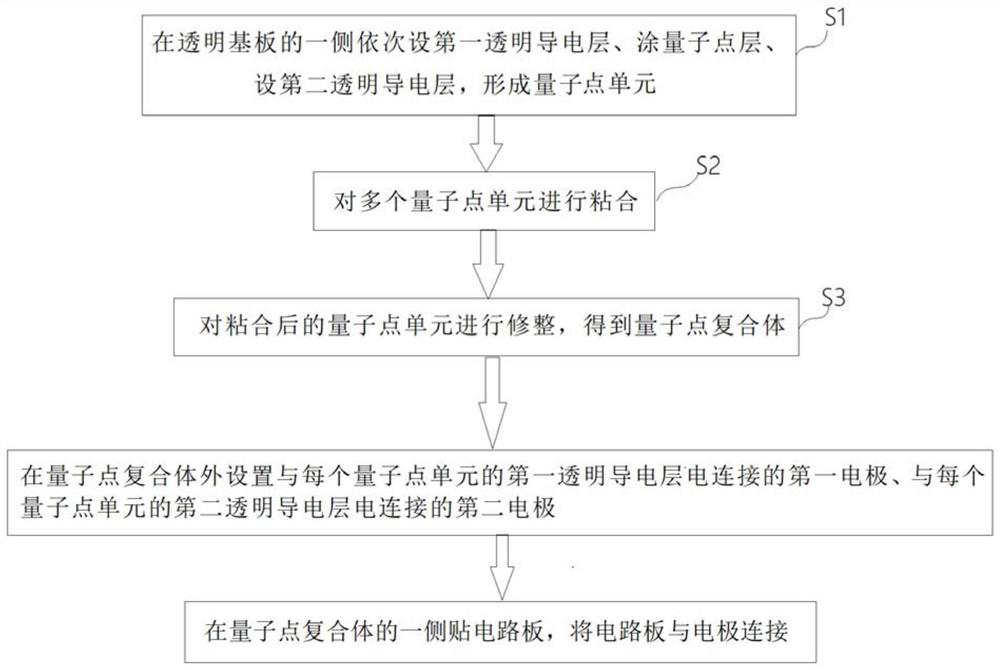

[0116] Such as figure 2 Manufacturing process flow for the quantum dot complex 100 of the embodiment

[0117] 1) Preparation of transparent substrate 11: image 3 For transparent substrates, select ultra-thin glass plates produced by float method, overflow stretching method, slit stretching method and double stretching method, the thickness of the substrate is 0.1-5mm, and the surface shape of the glass plate is tested. Ensure that the parallelism and flatness error of the upper and lower glossy surfaces does not exceed ±2μm. The length a and width b of the transparent substrate 11 are preferably: 1mm≤a≤500mm, 1mm≤b≤500mm. In addition, a resin-based transparent flat plate can also be selected as the base material.

[0118] 2) Quantum dot application process:

[0119] Such as Figure 4 , The single-layer quantum dot unit 10 structure processing technology. Figure 5 For the shape feature of each laye...

Embodiment 2

[0145] Embodiment 2: lamination method makes laminated material

[0146] to complete Figure 5 stacking process

[0147] The stacking process is as follows: Figure 19 , Figure 20 , Figure 21 , take a piece to complete Figure 5 A flat plate in the process is placed on the flat tooling, and the upward side is coated with "I"-shaped adhesive 60, and another piece is taken to complete Figure 5 A flat plate of the process is placed on the adhesive 60 in the same direction as the quantum dot unit 10 on the first flat plate, that is, the quantum dot unit 10 is all facing up or all facing down, and the preferred viscosity of the adhesive 60 is less than 1000cps, the curing method is heat curing or natural curing at room temperature, the adhesive 60 is epoxy resin or acrylic resin, preferably the volume shrinkage of the adhesive 60 is less than 1.1% after curing, and the adhesive 60 is cured After the Shore hardness is 60D-80D, the adhesive 60 is defoamed before being poured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com