Method for recognizing and evaluating major safety risk of metal smelting enterprise

A metal smelting and safety risk technology, applied in complex mathematical operations, instruments, data processing applications, etc., can solve the problems of long production chain, safety production accidents, inability to adapt to metallurgical enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

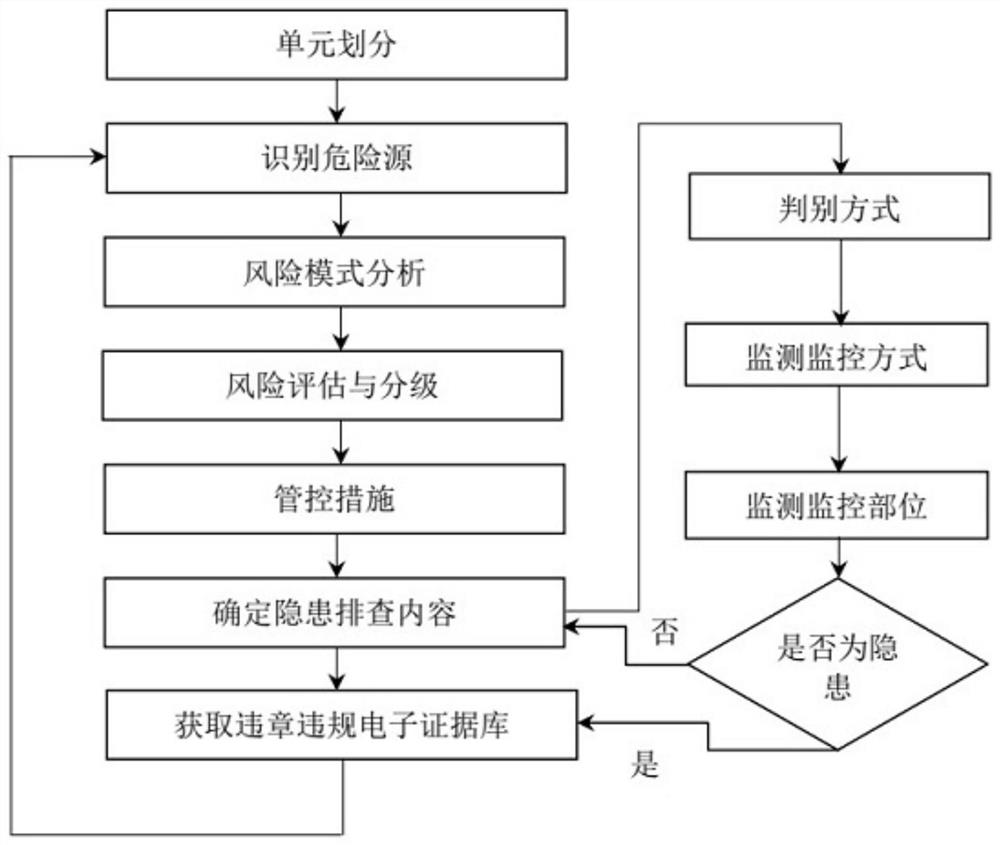

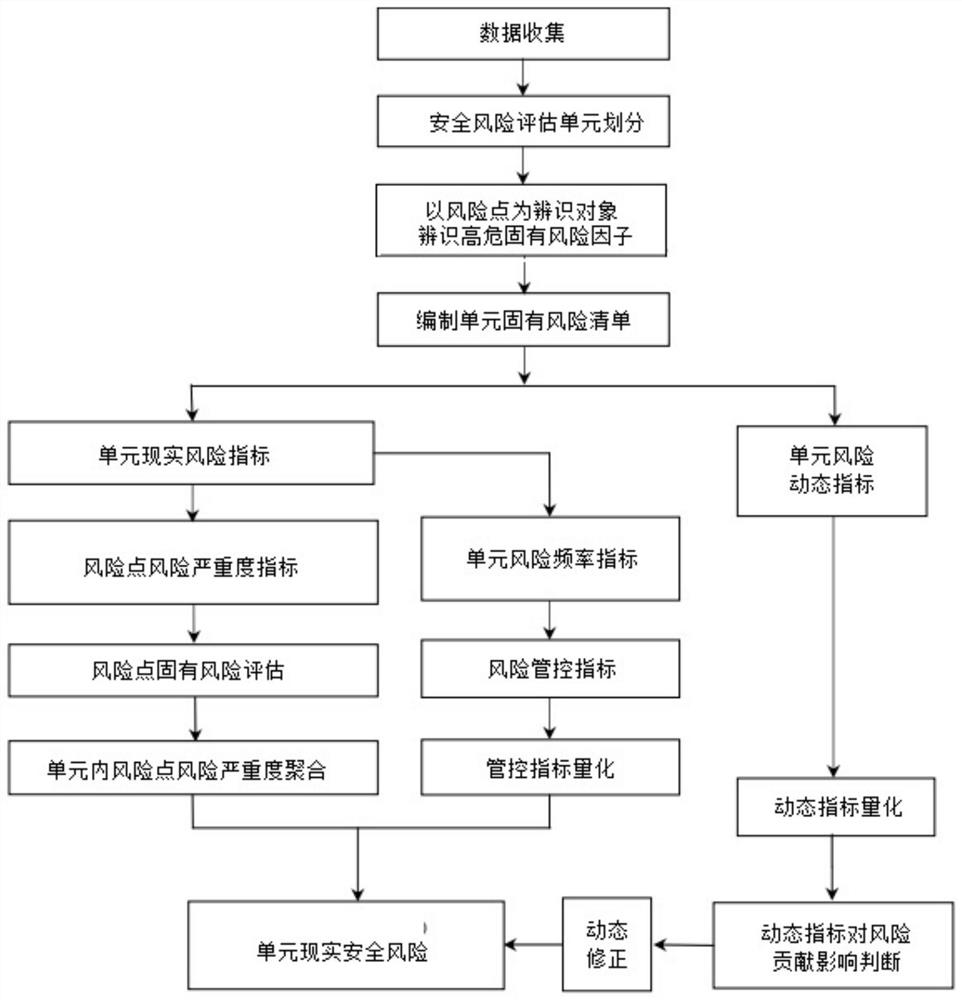

Method used

Image

Examples

Embodiment

[0238] Example: Taking a steel company as an example, this method is used for risk identification and assessment, and ironmaking and steelmaking are evaluated as two units of the entire system.

[0239] Significant risk assessment for ironmaking units.

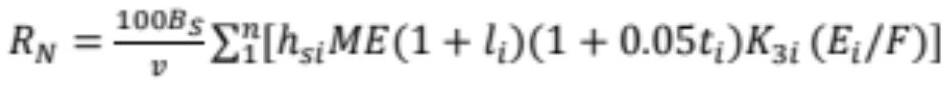

[0240] 1. Quantification of high-risk inherent risk indicators: The four risk points of blast furnace collapse accidents, molten metal accidents, gas accidents, and powder explosion accidents are taken as the focus of identification and evaluation of high-risk inherent risks.

[0241] (1) Risk points of blast furnace collapse accidents.

[0242] High-risk equipment and facilities—blast furnace body, based on the intrinsic safety level of blast furnace equipment and facilities, represents the level of technical measures to prevent accidents in production equipment and facilities at risk points of blast furnace collapse accidents, with a value range of 1.1 to 1.7.

[0243] The blast furnace is currently running smoothly, with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com