Method for improving aerobic composting effect of cephalosporin fermentation mushroom dregs by using electron beam irradiation

An electron beam irradiation, cephalosporin technology, applied in the application, fertilization device, radiation treatment and other directions, can solve the problems of slow degradation of antibiotics, prolonged composting time, affecting safety, etc. No effect of drug-resistant bacterial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

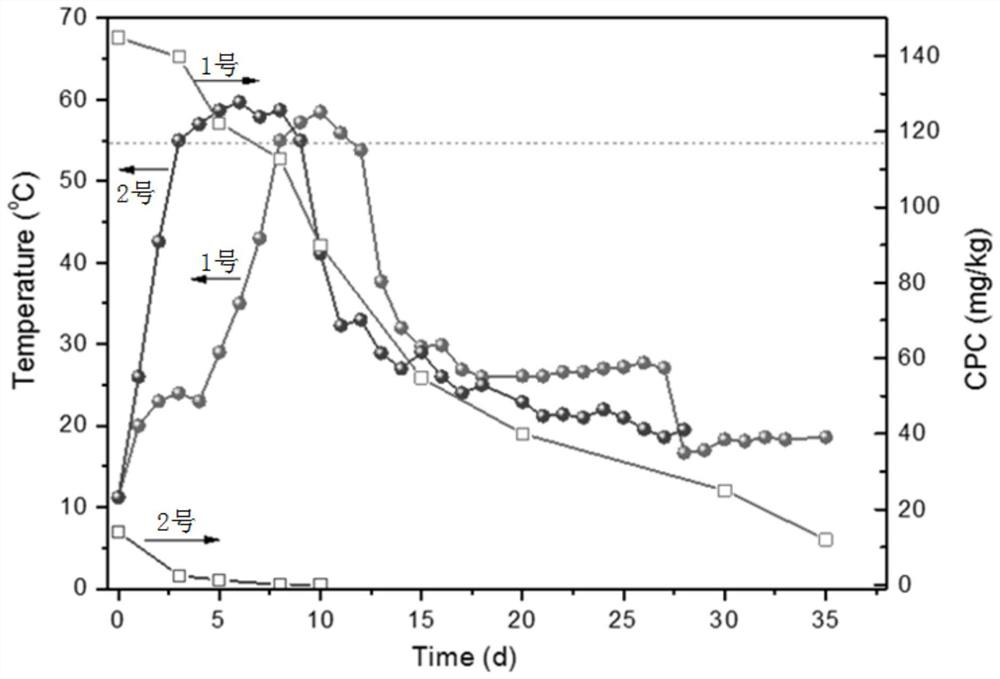

[0036] The fermentation residue of cephalosporin C was taken from an antibiotic production enterprise in Xinjiang. Its water content was 90%, the C / N ratio was 4.7, the pH value was 3.5, and the volatile suspended solids (VSS / total suspended solids (TSS) ratio was 94. %, protein and polysaccharide content were 10g / kg and 31g / kg.

[0037] The original sample-I of cephalosporin fermentation residue and the compost sample-II after electron beam irradiation were tested respectively.

[0038] CPCs were first extracted with phosphate buffered saline (PBS), and detected by liquid chromatography. Wherein, the liquid chromatograph used is a high-performance liquid chromatograph (Agilent 1200) from Agilent Company of the United States, the chromatographic column is an XDB-C18 reversed-phase column, and the column temperature is 30°C. The detector is an ultraviolet detector, and the detection wavelength is 260nm; the mobile phase is acetonitrile and 0.1% formic acid aqueous solution, an...

Embodiment 2

[0062] The DOCPC fermentation residue was taken from an antibiotic production enterprise in Xinjiang. Its water content was 91%, the C / N ratio was 5.4, the pH value was 3.5-4.0, and the volatile suspended solids (VSS) / total suspended solids (TSS) ratio was 87.7 %, protein and polysaccharide content were 23.2g / kg and 19.6g / kg.

[0063] 1) The DOCPC fermented bacteria residue is firstly treated with electron beam irradiation, and its specific process is:

[0064] Take about 5kg of bacteria residue and put it into a sample bag, spread it into a thin layer to expand the irradiation area and make the irradiation more uniform and sufficient; then send it to the irradiation room of the electron accelerator for irradiation by a conveyor belt and transmission speed to obtain different absorbed radiation doses of 0, 5kGy, 10kGy, 25kGy and 50kGy. The concentration of DOCPC, protein and polysaccharide in the bacteria residue before and after irradiation were detected respectively.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com