Acid-resistant spray coating suitable for globe roof of hot-blast stove

A technology of spraying paint and hot blast furnace, which is applied in the field of refractory materials, can solve the problems of poor high-temperature performance, reduced strength, and high Na content, and achieve the effects of stable volume, increased strength, and accelerated polycondensation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]An acid-resistant spray paint suitable for the dome of a hot blast stove. The components and their mass percentages are: mullite aggregate 53%, 70 high alumina powder 21%, α-Al 2 o 3 Micropowder 4%, quartz powder 3%, kyanite particles 4%, sodium carboxymethyl starch 0.4%, magnesium oxide 1.2%, amino-modified silane coupling agent 0.5%, modified quick-drying silica sol 12.9%.

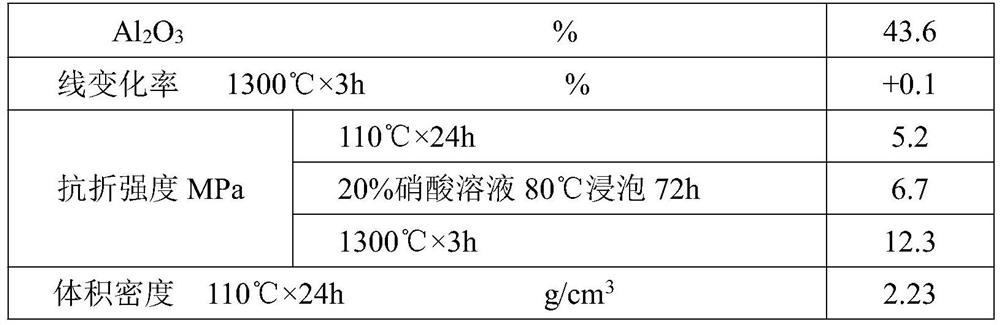

[0043] According to the above formula, the two-component spray paint (powder and binder) is packaged and transported to the construction site, the powder and a small amount of binder are mixed and stirred evenly, and then sent to the sprayer, and the remaining silica sol is added at the position of the gun mouth and adjusted to Appropriate addition amount, use the semi-dry spraying method to spray the top part of the hot blast stove. The performance test results of the acid-resistant spray paint obtained in Example 1 are shown in Table 1.

[0044] Table 1

[0045]

Embodiment 2

[0047] An acid-resistant spray paint suitable for hot blast stove domes, the components and their mass percentages are: mullite aggregate 57%, 70 high alumina powder 16.2%, α-Al 2 o 3 Micropowder 6%, quartz powder 5%, kyanite particles 2%, propylene glycol alginate 0.3%, magnesium oxide 0.8%, amino-modified silane coupling agent 0.4%, modified quick-drying silica sol 12.3%.

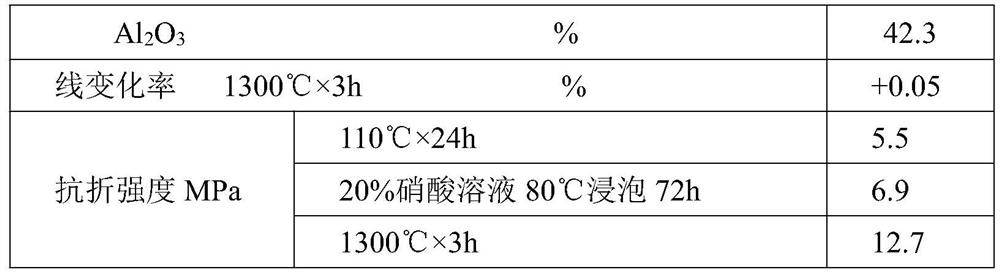

[0048] According to the above formula, the two-component spray paint (powder and binder) is packaged and transported to the construction site, the powder and a small amount of binder are mixed and stirred evenly, and then sent to the sprayer, and the remaining silica sol is added at the position of the gun mouth and adjusted to Appropriate addition amount, use the semi-dry spraying method to spray the top part of the hot blast stove. The performance test results of the acid-resistant spray paint obtained in Example 2 are shown in Table 2.

[0049] Table 2

[0050]

[0051]

Embodiment 3

[0053] An acid-resistant spray paint suitable for hot blast furnace domes, the components and their mass percentages are: mullite aggregate 52%, 70 high alumina powder 21.7%, α-Al 2 o 3 Micropowder 5%, quartz powder 4%, kyanite particles 3%, sodium carboxymethyl starch 0.5%, magnesium oxide 1%, amino-modified silane coupling agent 0.3%, modified quick-drying silica sol 12.5%.

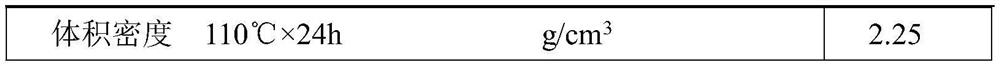

[0054] According to the above formula, the two-component spray paint (powder and binder) is packaged and transported to the construction site, the powder and a small amount of binder are mixed and stirred evenly, and then sent to the sprayer, and the remaining silica sol is added at the position of the gun mouth and adjusted to Appropriate addition amount, use the semi-dry spraying method to spray the top part of the hot blast stove. The performance test results of the acid-resistant spray paint obtained in Example 3 are shown in Table 3.

[0055] table 3

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com