Microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and ceramics, applied in the field of ceramic materials, can solve the problems of complex process, poor temperature stability and poor mechanical properties of microwave dielectric ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

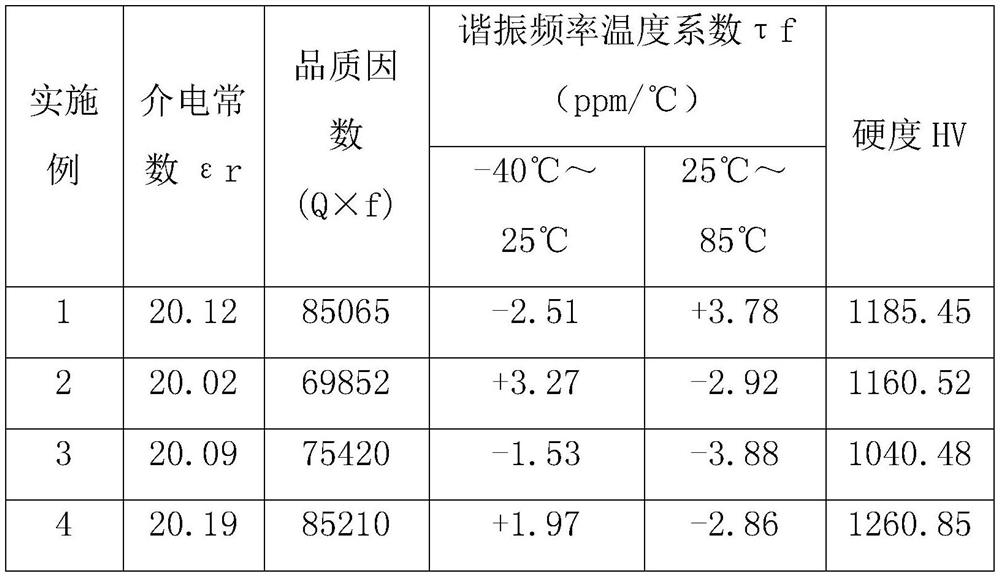

Examples

preparation example Construction

[0032] The preparation method of the microwave dielectric ceramic of the present invention may comprise the following steps:

[0033] (1) MgO and TiO with a purity of more than 99% 2 , CaCO 3 As the raw material, according to the composition expression aMgTiO 3 -bCaTiO 3 According to the molar ratio of each element in the compound, it is first dissolved in deionized water, then fully mixed by ball milling, dried and pre-fired to obtain magnesium-calcium-titanium system ceramics, which are used as the main material of microwave dielectric ceramics.

[0034] Wherein, the drying temperature is 200°C. The technical parameters of pre-burning are: the pre-burning temperature is 1000°C-1200°C, and the pre-burning time is 2-6 hours.

[0035] (2) Doping with sintering aids with a purity of more than 99.9%: relative to the mass of the main material, weigh MnO according to the mass fraction 2 , Fe 2 O 3 , ZnO, SiO 2 , Nb 2 O 5 , Cr 2 O 3 , La 2 O 3 , NiO, ZrO 2 and Nd 2 O...

Embodiment 1

[0040] Microwave dielectric ceramic 0.955MgTiO 3 -0.045CaTiO 3 -MnO 2 -SiO 2 , is the sintering aid MnO 2 and SiO 2 Doped magnesium perovskite ceramics, where MnO 2 Relative to the main material 0.955MgTiO 3 -0.045CaTiO 3 The mass fraction of SiO is 0.21%; SiO 2 0.955MgTiO relative to the main material 3 -0.045CaTiO3 The mass fraction is 0.13%.

[0041] The preparation method of the above-mentioned microwave dielectric ceramics comprises the following steps:

[0042] (1) MgO and TiO with a purity of more than 99% 2 , CaCO 3 as raw material, dissolved in deionized water, and then ball milled to mix evenly, and the prepared mixed solution was dried in an oven at 200°C, crushed, and sieved; the powder obtained by sieving was pre-calcined, and the pre-calcined temperature was 1000°C, pre-fired for 2 hours to obtain the main material magnesium perovskite ceramic powder;

[0043] (2) Add sintering aid MnO to magnesium perovskite ceramic powder 2 and SiO 2 , dispersant...

Embodiment 2

[0045] Microwave dielectric ceramic 0.955MgTiO 3 -0.045CaTiO 3 -SiO 2 -ZrO 2 -Fe 2 o 3 , as the sintering aid SiO 2 , ZrO 2 and Fe 2 o 3 Doped magnesium perovskite ceramics, where SiO 2 Relative to the main material 0.955MgTiO 3 -0.045CaTiO 3 The mass fraction of ZrO is 0.15%; ZrO 2 0.955MgTiO relative to the main material 3 -0.045CaTiO 3 The mass fraction is 0.91%; Fe 2 o 3 0.955MgTiO relative to the main material 3 -0.045CaTiO 3 The mass fraction is 0.18%.

[0046] The preparation method of the above-mentioned microwave dielectric ceramics comprises the following steps:

[0047] (1) MgO and TiO with a purity of more than 99% 2 , CaCO 3 Dissolve in deionized water as raw material, and then ball mill and mix thoroughly; place the prepared mixed solution in an oven at 200°C for drying, crush, and sieve; The temperature is 1050°C, and the pre-firing time is 2 hours to obtain the main material magnesium perovskite ceramic powder;

[0048] (2) Add sintering a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com