Dosing device production system

A production system and drug delivery technology, applied in the directions of packaging, packaging item types, packaging machines, etc., can solve the problems of low production efficiency, pollution of the drug delivery device, and high labor costs, so as to improve production efficiency, reduce personnel contact, and reduce The effect of the probability of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

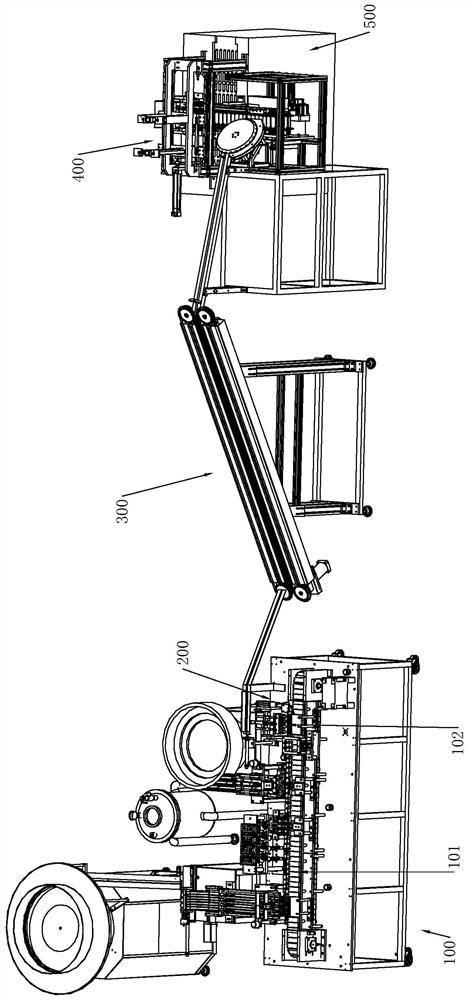

[0093] Such as figure 1 As shown, a production system of a drug delivery device includes: a filling machine 100 and a packaging machine 500, between which a turning and unloading device 200, a conveying device 300 and a swinging material device 400 are arranged, through which the turning and unloading device 200. The cooperation between the conveying device 300 and the swinging device 400 automatically transports the filled dispensing device 1 into the packaging machine 500 and puts it well, and then performs packaging, and completes the filling of the dispensing device 1 The entire production process to packaging.

[0094] The specific structure is as follows:

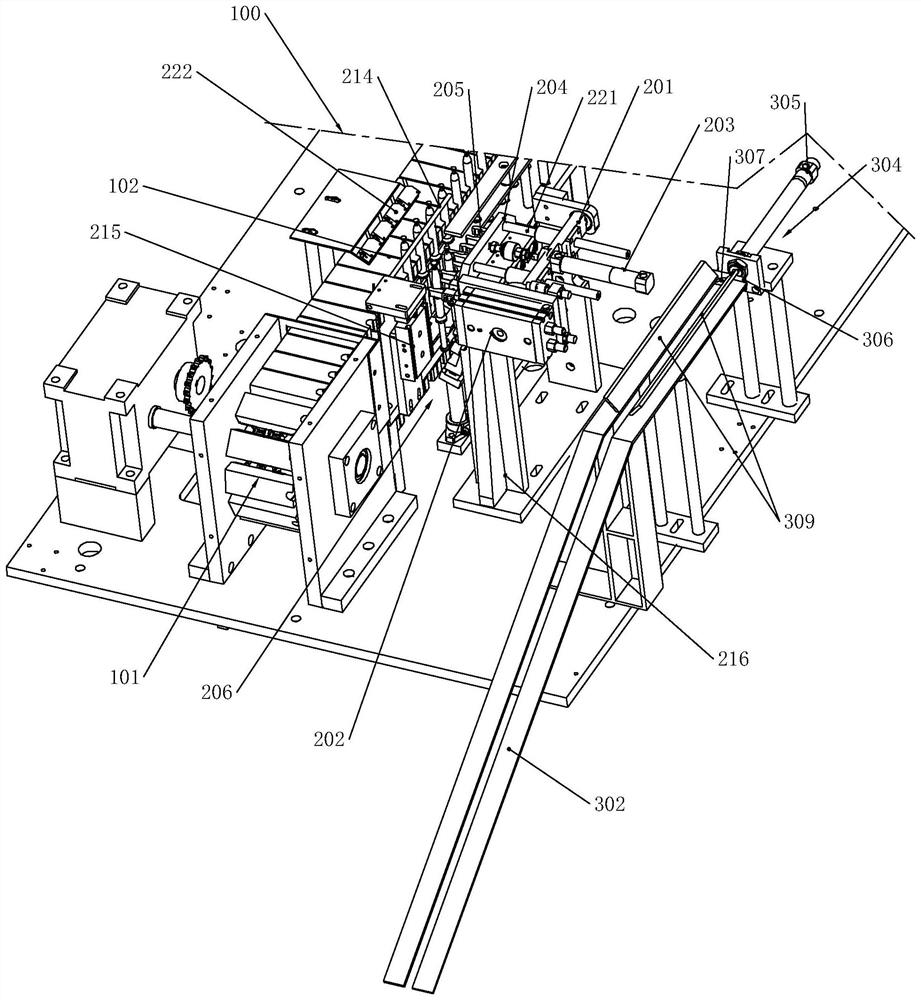

[0095] Such as figure 2 and Figure 4 As shown, the flipping blanking device 200 is installed on the frame of the blanking area 102 of the filling machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com