Spraying equipment for socket type large-diameter plastic-coated steel pipe

A technology of plastic-coated steel pipes and spraying equipment, which is applied in the direction of surface coating liquid devices, coatings, spray booths, etc., which can solve the problems of time-consuming and labor-intensive personnel, cumbersome operation steps, and waste of time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

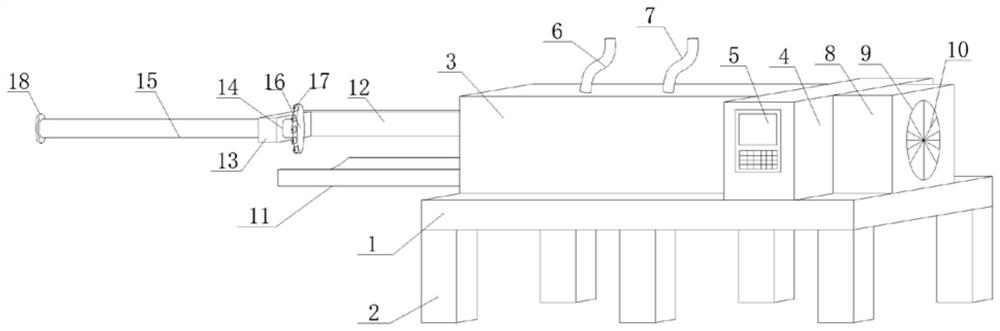

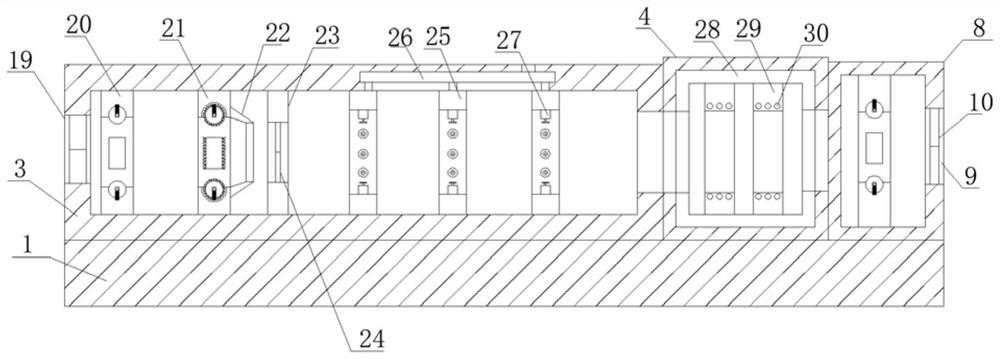

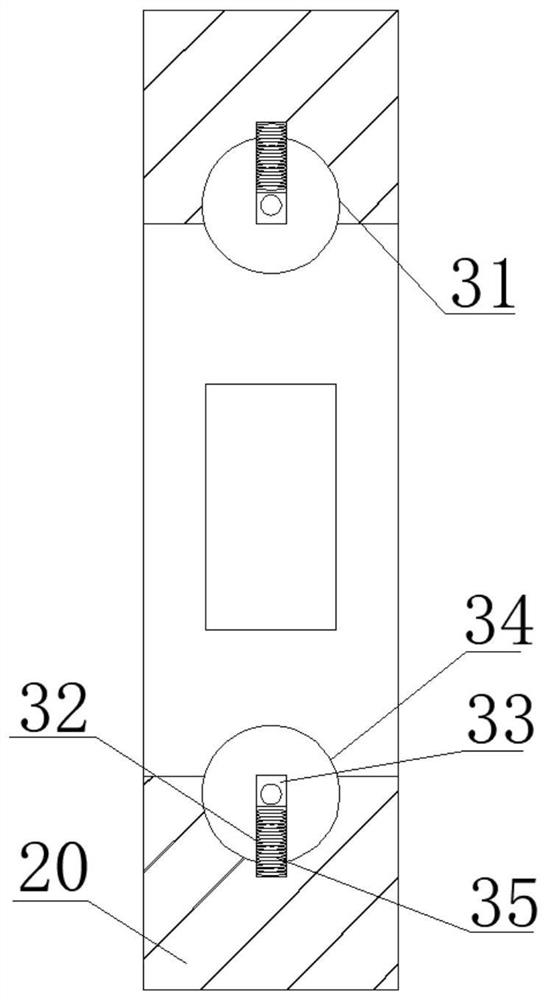

[0027] see Figure 1-2, in an embodiment of the present invention, a spraying equipment for socket-type large-diameter plastic-coated steel pipes, including a fixed base plate 1, the bottom surface of the fixed base plate 1 is welded vertically downward with a support pole 2, and the top surface bolts of the fixed base plate 1 The spraying main box 3 is connected, the number of support poles 2 is multiple, and the multiple support poles 2 are arranged parallel to each other, and the top surfaces of the multiple support poles 2 are welded vertically upward to the bottom surface of the fixed base plate 1 close to At the edge position, the spraying main box 3 is fixed horizontally on the top surface of the fixed bottom plate 1 near one end, and one end of the spraying main box 3 is docked at the side of the baking main box 4, and the top surface of the fixed bottom plate 1 is bolted. Baking main box 4, one side of baking main box 4 is inlaid with control panel 5, the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com