Low-temperature flue gas dry desulfurization process for preheating desulfurizer

A low-temperature flue gas and dry desulfurization technology, applied in the field of flue gas desulfurization, can solve the problems of increased energy consumption, low efficiency, and low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

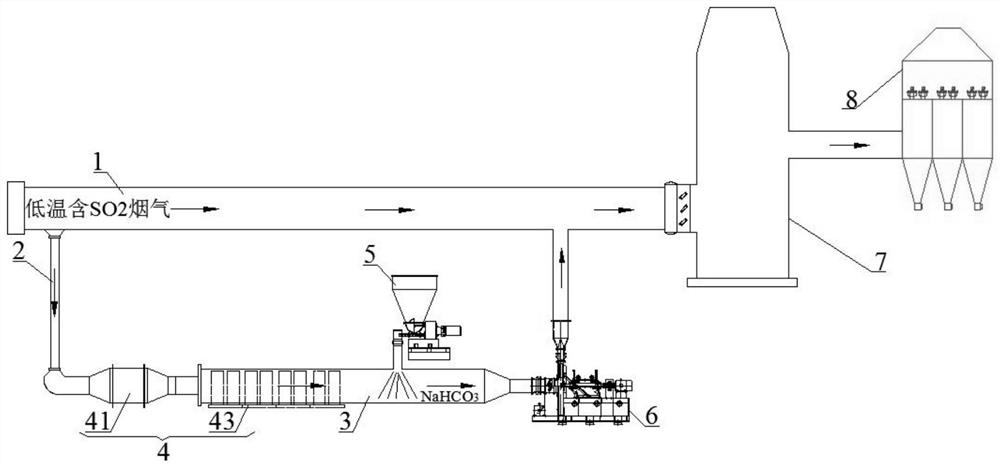

[0055] refer to figure 2 As shown, the low-temperature flue gas dry desulfurization method of preheating the desulfurizer in this embodiment includes the following steps: the flue gas from the coke oven charging coal, coking and dedusting enters the low-temperature flue gas main pipeline 1 through the gas intake point, and flows through the low-temperature flue gas auxiliary pipe 1. The pipeline 2 enters the heating device 4. In this embodiment, the heating device 4 is a gas-gas heat exchange device 41 and an electric heating device 43 for co-heating. , the gas-gas heat exchange device 41 is a steam heat exchanger, through the steam heat exchanger, the temperature of the flue gas from coke charging and dust removal in the coke oven is heated to 130°C, and then enters the electric heating device 43, which is an electric heater , the electric heater heats the temperature of the flue gas from coke oven charging and dedusting to 250°C; then the hot flue gas at 250°C enters the mi...

Embodiment 2

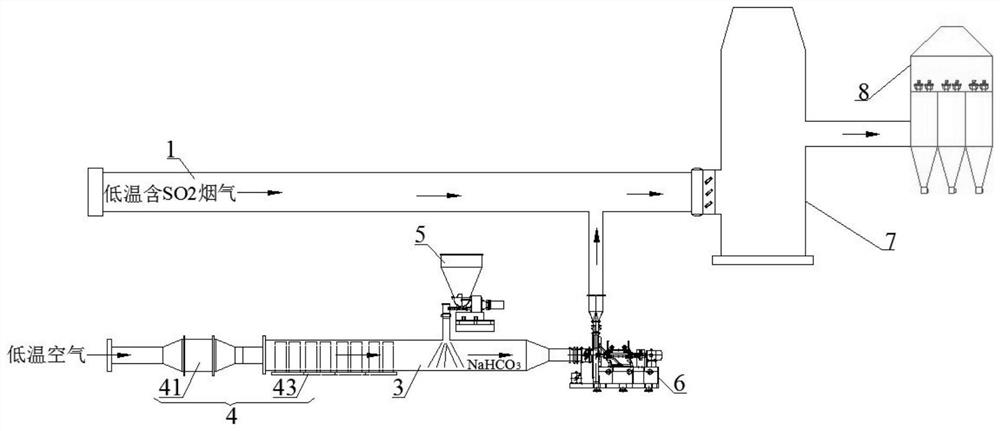

[0057] refer to image 3 As shown, the low-temperature flue gas dry desulfurization method of preheating the desulfurizer in this embodiment includes the following steps: the outdoor low-temperature air enters the gas-gas heat exchange device 41 through the left end of the high-temperature flue gas pipeline 3, and the heating device in this embodiment 4 is air-gas heat exchange device 41 and electric heating device 43 cooperative heating, the outdoor low-temperature air enters the air-gas heat exchange device 41 first, and the gas-gas heat exchange device 41 is a steam heat exchanger, which heats the outdoor air through the steam heat exchanger. The air temperature reaches 130°C, and then enters the electric heating device 43, the electric heating device 43 is an electric heater, and the electric heater heats up the hot air to 250°C; after that, the 250°C hot air enters the middle section of the high-temperature flue gas pipeline 3, which is called 600-800 mesh NaHCO injected ...

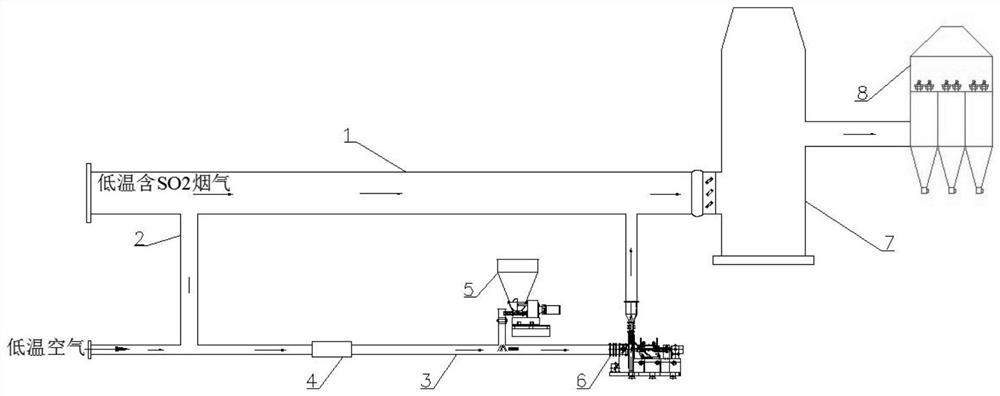

Embodiment 3

[0059] refer to Figure 4 As shown, the low-temperature flue gas dry desulfurization method of preheating the desulfurizer in this embodiment includes the following steps. The flue gas auxiliary pipe 2 enters the heating device 4. In this embodiment, the heating device 4 is a hot air heating device 44, and the hot air heating device 44 is a hot blast stove. The combustion medium of the hot blast stove is coke oven gas / blast furnace gas / natural gas, etc.; then the hot flue gas at 250°C enters the middle section of the high-temperature flue gas pipeline 3, and is mixed with the 600-800 mesh NaHCO injected by the weighing feeder 5 3 Fine powder for mixing, pre-decomposing NaHCO 3Fine powder, before the desulfurizer enters the low-temperature flue gas main pipeline 1 and mixes with the coke oven coal charging and dedusting flue gas to activate the activity of the desulfurizer; The main gas pipeline 1 is evenly mixed with the flue gas from coke oven charging and dedusting, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com