Preparation method of lithium-free flexible electrode by using ion exchange method

An ion exchange method and flexible electrode technology, applied in the direction of active material electrodes, positive electrodes, battery electrodes, etc., can solve the problems of restricting the development of flexible electrodes, poor ion diffusion rate, and low electronic conductivity, so as to improve electrical properties and conduct electricity. The effect of enhancing the effect and reducing the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

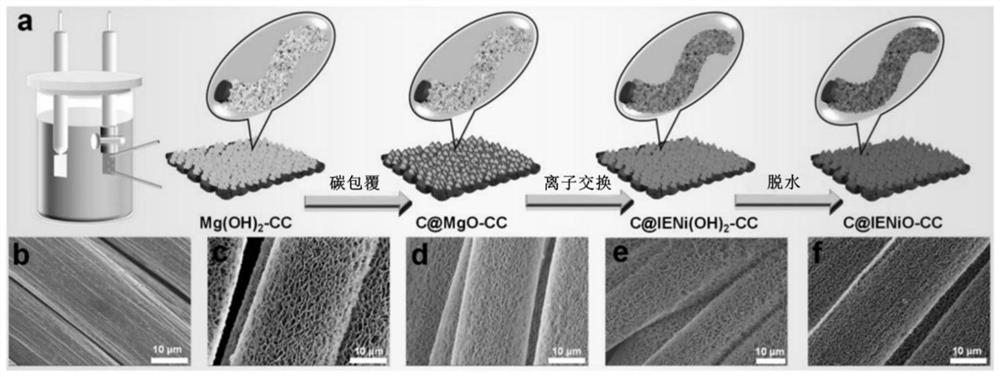

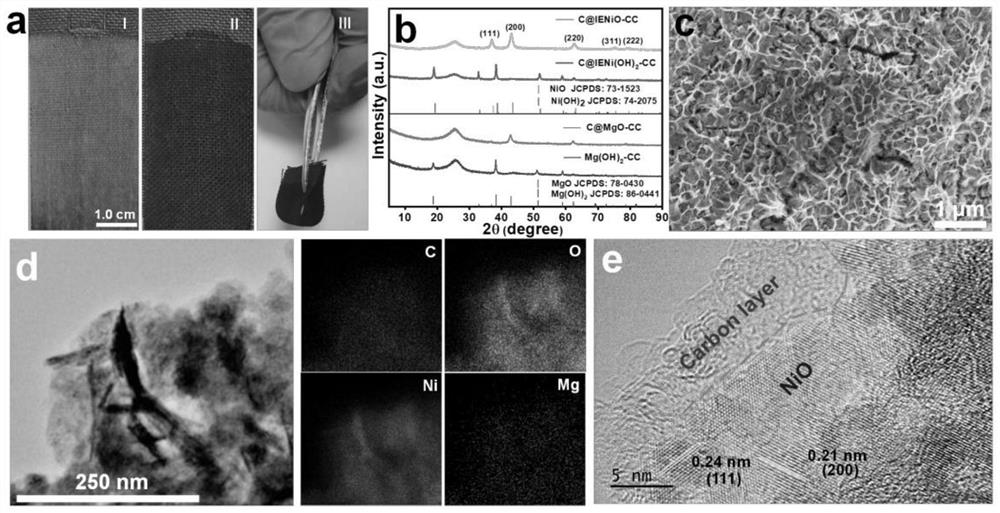

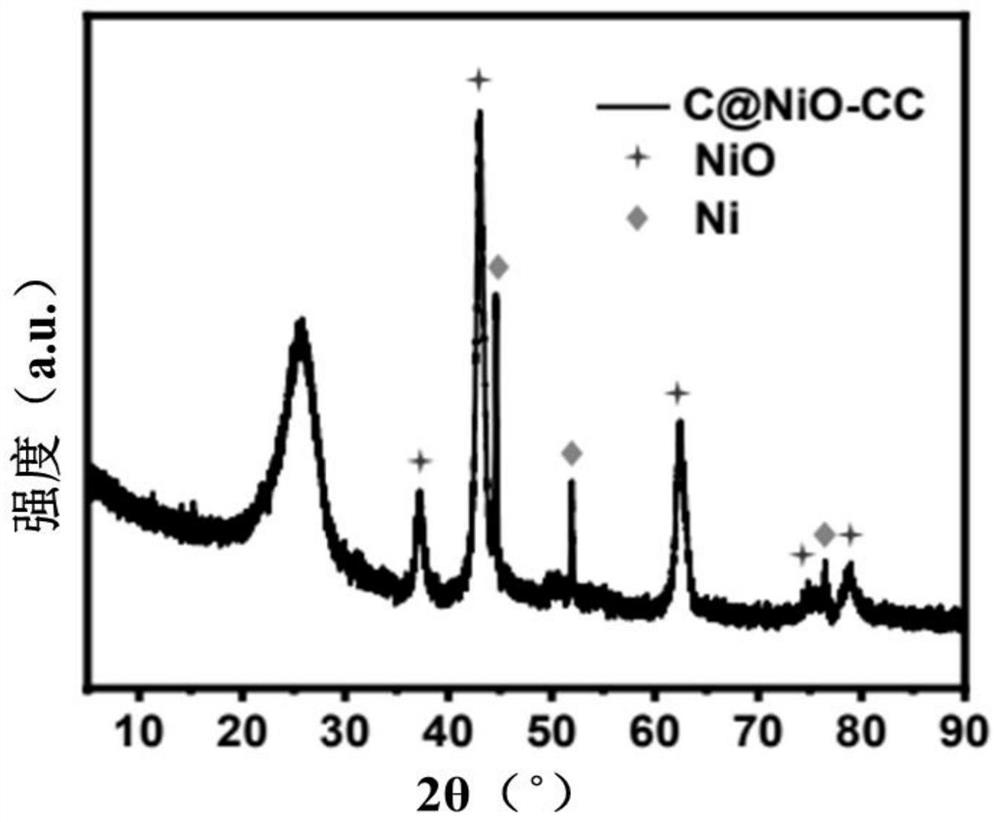

[0034] The invention provides a method for preparing a lithium-free flexible electrode by an ion exchange method, comprising the following steps:

[0035] S1. Deposit magnesium hydroxide on carbon cloth by electrochemical deposition to obtain a magnesium hydroxide-carbon cloth composite;

[0036] S2. Immerse the magnesium hydroxide-carbon cloth composite obtained in step S1 into an aqueous glucose solution and perform hydrothermal treatment; then wash and dry the product obtained after the hydrothermal treatment and perform high-temperature carbonization treatment to obtain carbon-coated Magnesium oxide-carbon cloth composite;

[0037] S3. Immerse the carbon-coated magnesium oxide-carbon cloth composite obtained in step S2 into a nickel salt solution to perform an ion exchange reaction; then wash and dry the product of the ion exchange reaction and then calcine it under an inert atmosphere processed to obtain flexible electrodes.

[0038] In step S1, the deposition of magnes...

Embodiment 1

[0045] This embodiment provides a method for preparing a lithium-free flexible electrode by ion exchange, including the following steps:

[0046] S1, preparation of magnesium hydroxide-carbon cloth composite (Mg(OH) 2 -CC)

[0047] A standard two-electrode electrodeposition system was adopted, with platinum sheet and carbon cloth as the counter electrode and working electrode, respectively, and Mg(NO 3 ) 2 ·6H 2 O aqueous solution was used as the electrolyte, under the conditions of 0V and -24mA, the carbon cloth was deposited at room temperature for 1 h, and the carbon cloth was washed three times with distilled water, and then dried in an oven at 70 °C for 12 h to obtain the magnesium hydroxide-carbon cloth composite. substance, denoted as Mg(OH) 2 -CC.

[0048] S2. Preparation of carbon-coated magnesium oxide-carbon cloth composite (C@MgO-CC)

[0049] The magnesium hydroxide-carbon cloth composite obtained in step S1 was placed in a 50 mL autoclave containing 40 mL of...

Embodiment 2~5

[0073] Examples 2 to 5 respectively provide a method for preparing lithium-free flexible electrodes by ion exchange. Compared with Example 1, the difference is that the process parameters in steps S2 and S3 are changed. The process parameters corresponding to each embodiment are as follows: As shown in Table 1, the rest of the steps are consistent with those in Example 1, and will not be repeated here.

[0074] The processing parameter of table 1 embodiment 2~5

[0075]

[0076] Detecting the flexible electrodes prepared in Examples 2 to 5, it can be found that their morphology and electrical properties are basically the same as those in Example 1, indicating that the process parameters of each step can be properly adjusted within a certain range, and the obtained products can be used as high-quality electrodes. Flexible electrodes with high capacity are used in flexible lithium-ion batteries, which can meet the needs of actual production and application, and have a good ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com