A kind of preparation method of burnt-out polyester six-grid cloth

A burnt-out and polyester technology is applied in the field of the preparation of burnt-out polyester six-grid cloth, which can solve the problems of endless burnt-out of the bottom plate, poor elasticity of the cloth surface, scratches, etc., so as to reduce the corrosion strength, reduce the proportion, and increase the penetration. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0025] The preparation method of the burnt-out polyester six-grid cloth comprises the following steps:

[0026] Preparation of burnt-out alkaline slurry: by mass percentage, mix 1.5-2.5% alkaline burn-out paste, 6-8% sodium hydroxide powder, and 89.5-92.5% water to prepare burn-out alkaline slurry, control The slurry viscosity of burnt-out alkaline slurry is within 300Mpa.S, and the alkali-resistant penetrating agent and 0.2-0.5% of surfactant, which account for 1% of the mass of burnt-out alkaline slurry, are added before the slurry is loaded into the machine;

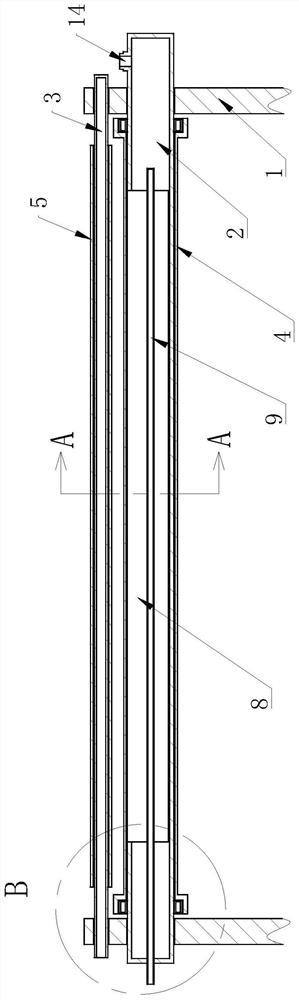

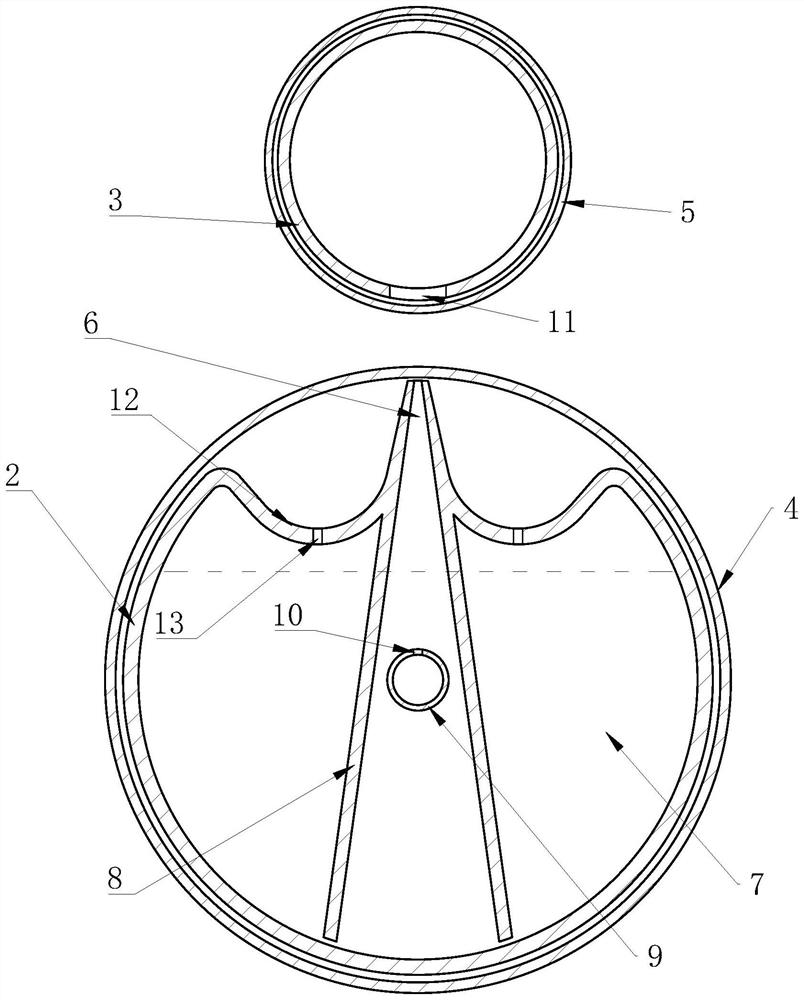

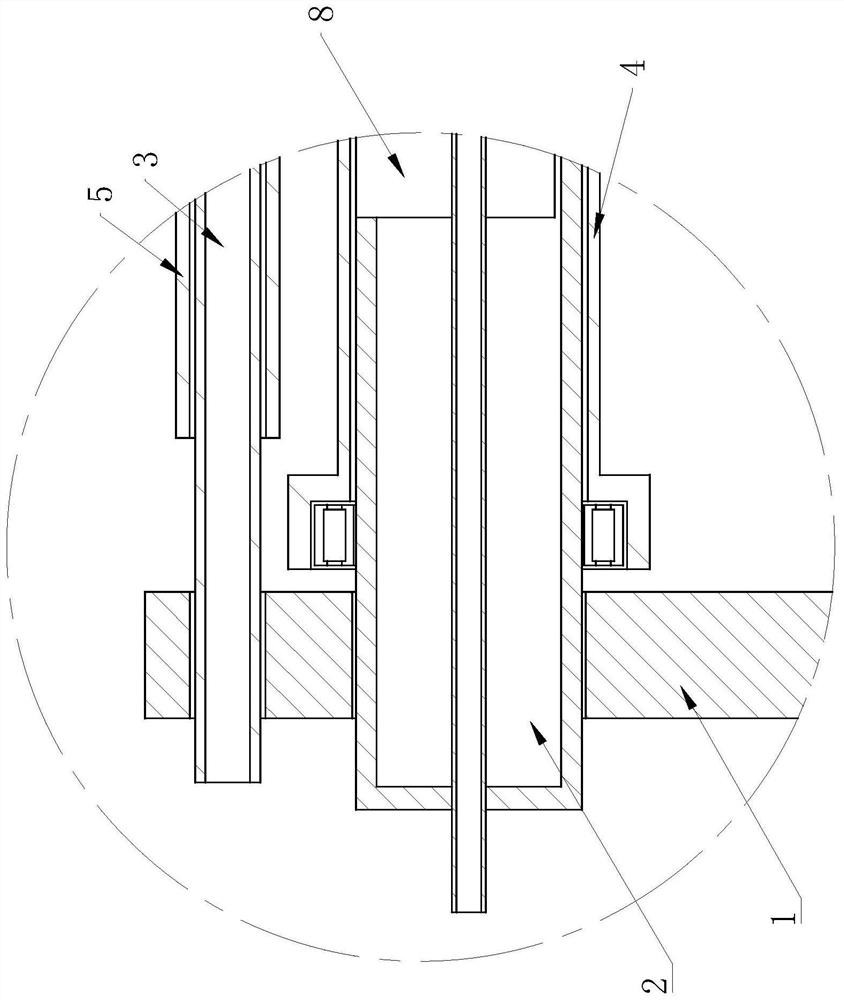

[0027] Burnt-out: Through the bubbling feeding mechanism, the pulling speed of the cloth is controlled within 5 m / min;

[0028] Steaming and washing process: Burnt-out sizing and dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com