Knitting machine knitting platform capable of quickly and automatically changing knitting tightness and knitting method

A technology of weaving density and weaving machine, which is applied in the direction of woven fabrics, textiles and papermaking to achieve the effect of realizing automatic production, improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

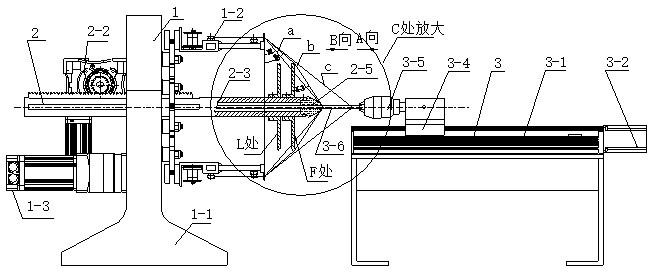

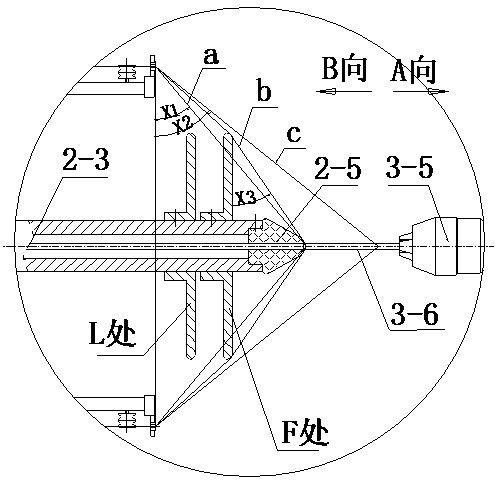

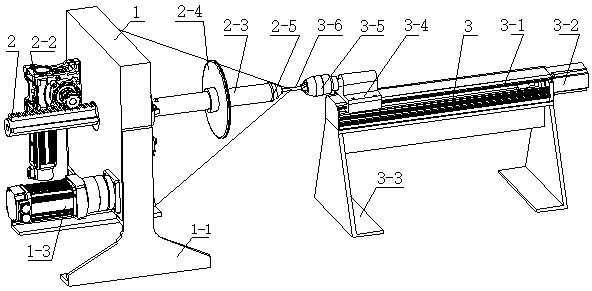

[0040] Embodiment 1: The present invention includes a weaving platform that changes the weaving density rapidly and automatically, and a weaving method based on the weaving platform.

[0041] The weaving platform includes: a weaving machine 1, a pallet expansion device 2 and a traction mechanism 3; the pallet expansion device 2 is installed on the weaving machine 1 and passes through the hole in the center of the weaving machine, and a traction mechanism 3 is arranged on one side of the weaving machine 1; The shaft core of the tray telescopic device 2 is the same shaft center as the working shaft core of the traction mechanism 3 .

[0042] The knitting machine 1 includes: a knitting main body 1-1, a walking spindle 1-2, a knitting power motor 1-3 and a dial 1-4; One side is connected with a weaving power motor 1-3; the other side of the weaving main body 1-1 is connected with a dial 1-4, and the dials 1-4 are evenly distributed around the central hole of the weaving main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com