Laying up method for twisting low-voltage multi-core cables by laying up drum twister

A technology for multi-core cables and cabling machines, which is used in cable/conductor manufacturing, circuits, electrical components, etc., and can solve the problem of uneven pitch between the head and tail of the cable core, the long distance between the pay-off tray and the parallel mold, and the problems of the cable core. Easy to back twist and other problems, to achieve the effect of good quality and appearance, high production efficiency, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

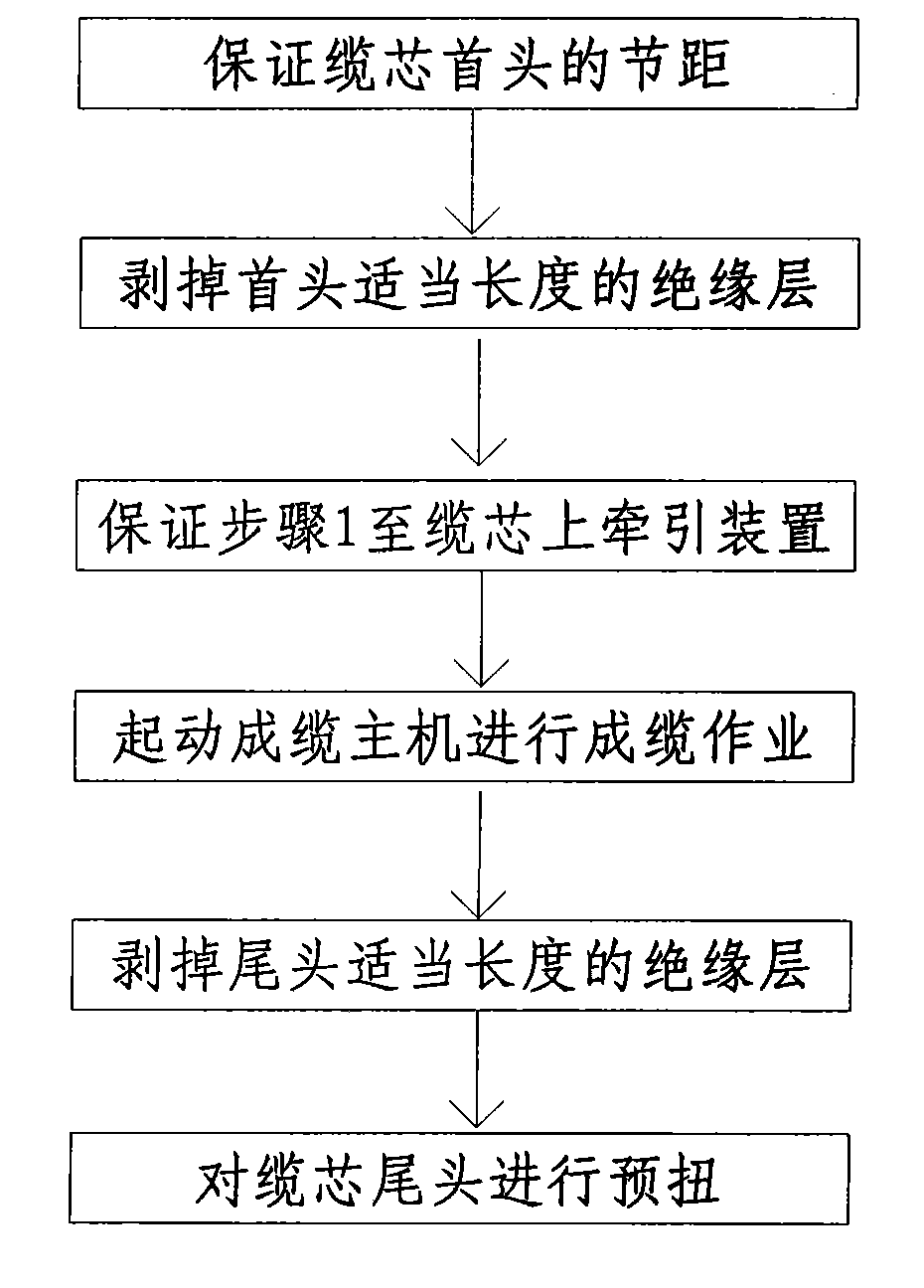

[0025] A cable forming method for low-voltage multi-core cable stranding by a disc cable forming machine, including the following processing technology:

[0026] Step 1. When driving for the first time, use the insulated wire core or steel wire rope as the traction line. Before the head of the line core reaches the traction device, use the method of reducing the traction speed or increasing the rotation speed of the twisted cage to maintain the pitch of the cable and prevent over-alignment. The cable core of the wire mold is twisted back;

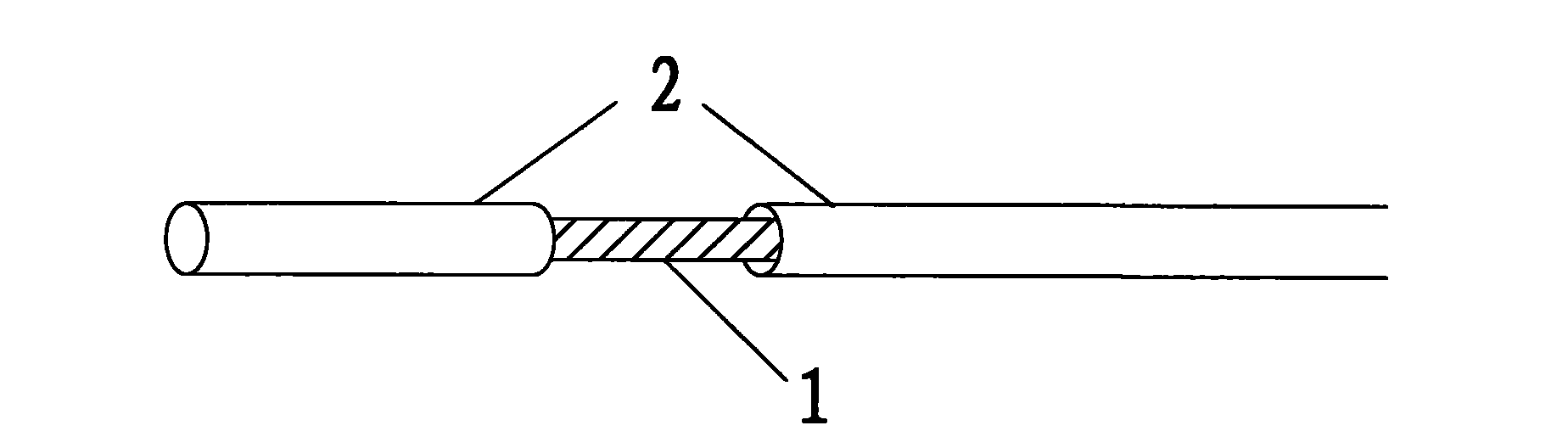

[0027] Step 2. At a distance of about 20 cm from the head of the cable core, peel off the insulation layer 2 of the cable core by about 10 cm, which greatly reduces the torsional force on the conductor and prevents the head of the cable core from leading a loose strand;

[0028] Step 3. Continue step 1 to the traction device on the cable core, so as not to cause serpentine phenomenon on the take-up reel;

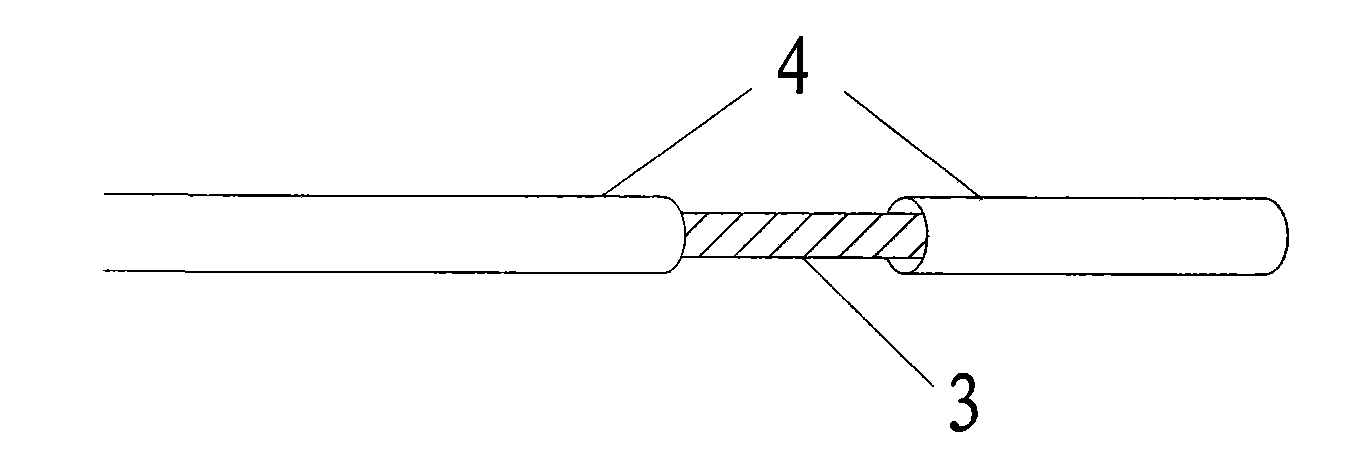

[0029] Step 4, start the cabling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com