Sword plate

A technology of supporting boards and splints, which is applied in the directions of slitting machinery, propulsion, earthwork drilling, etc., can solve the problems of long stop time and cost, and achieve the effect of reducing assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

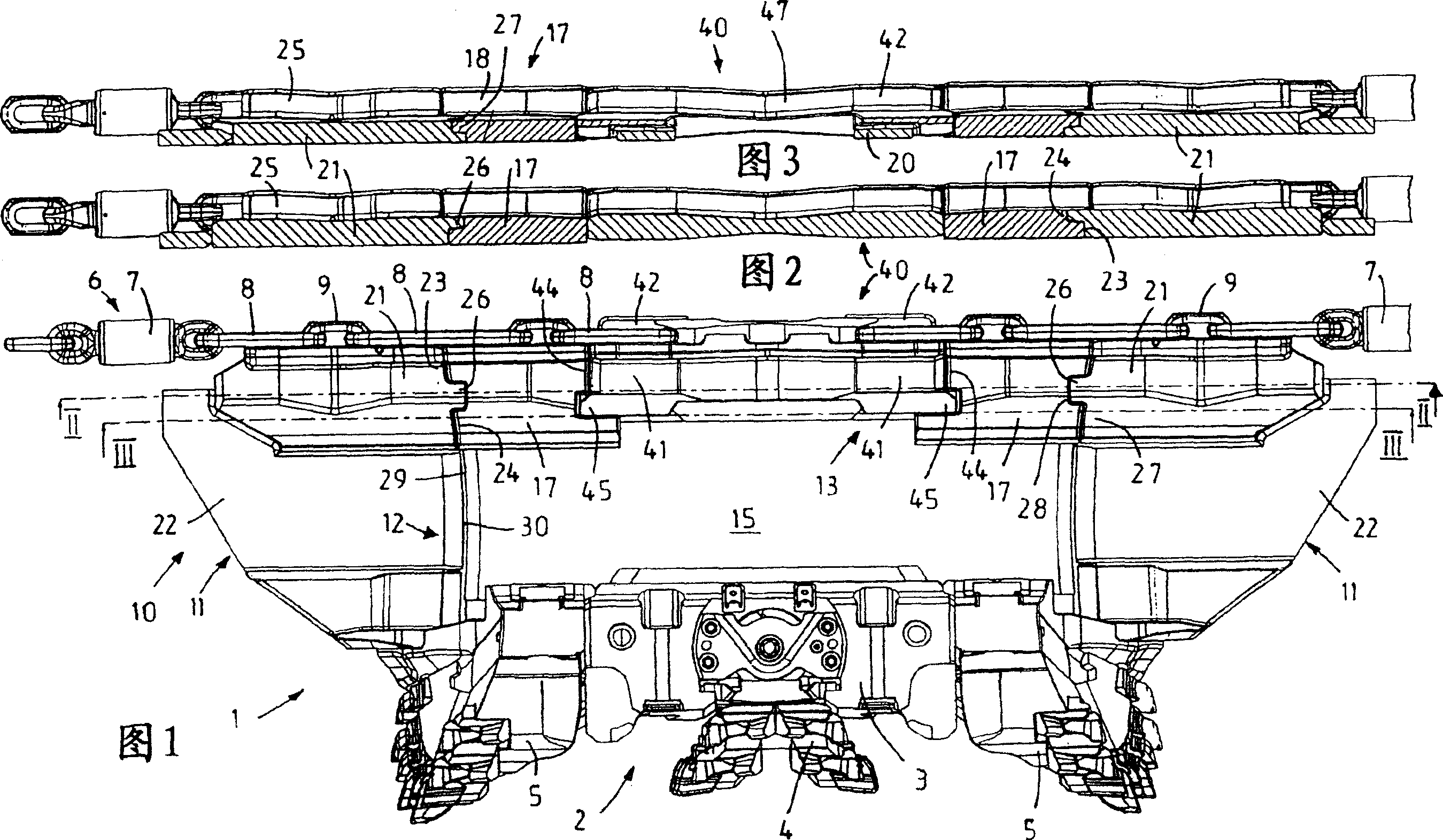

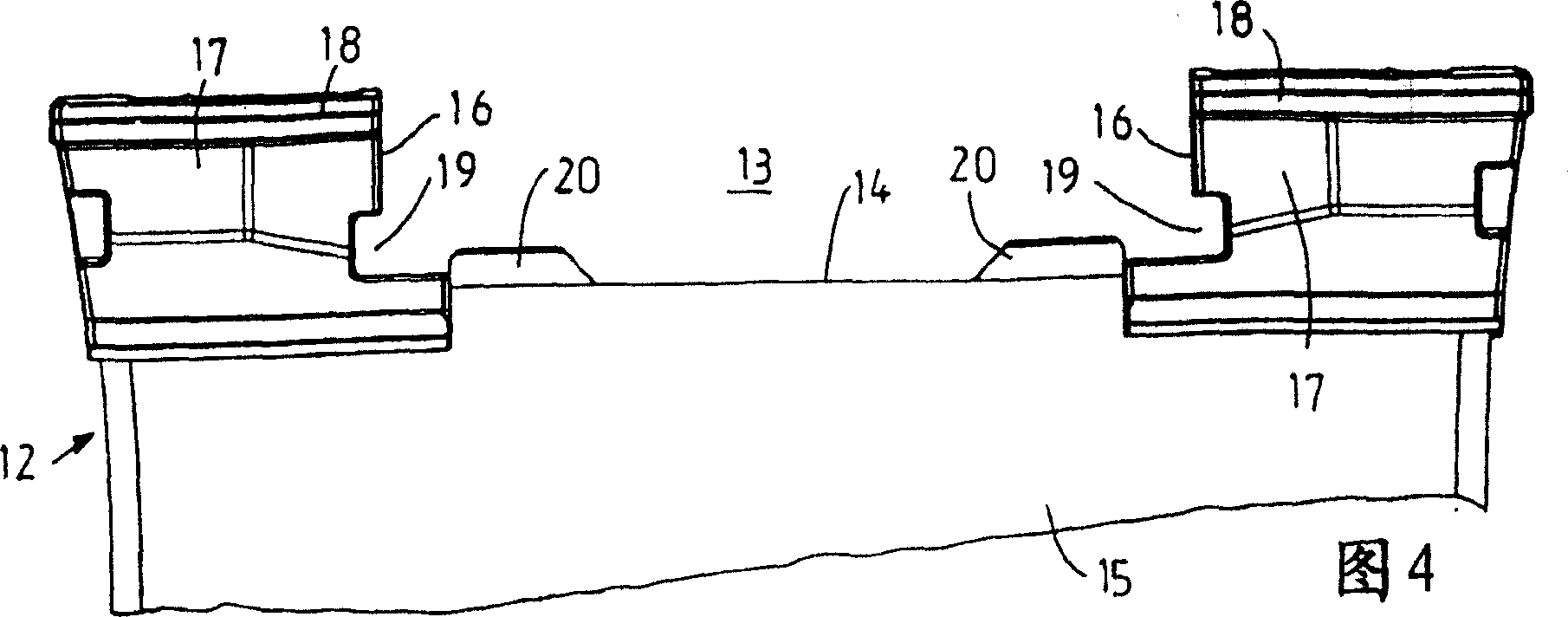

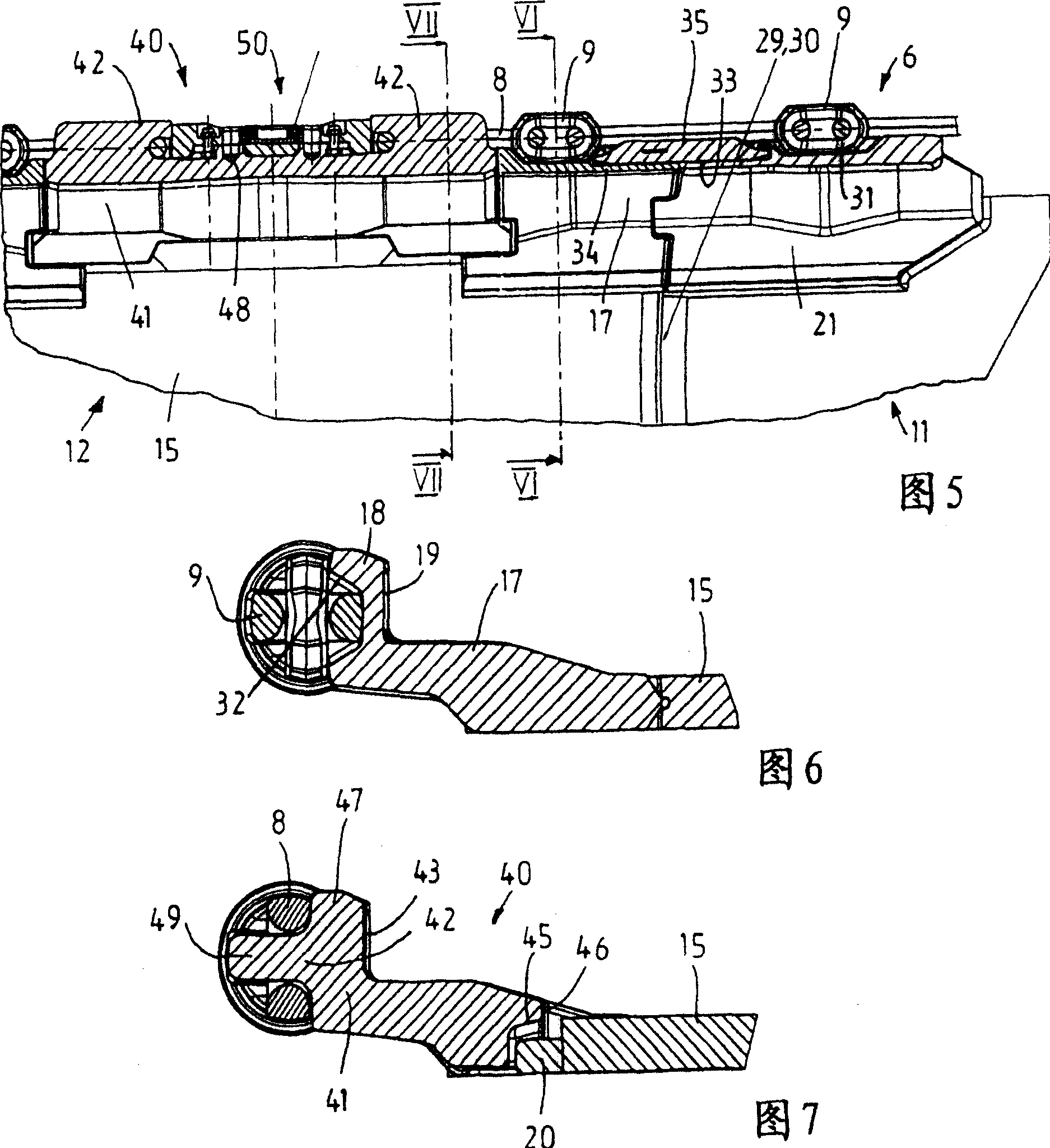

[0021] The tow-hook plow 1 shown in FIG. 1 can be used especially in coal mining as a coal plow for seam thicknesses of less than 1.5 m and optionally less than 0.6 m, which is designed as a tow-hook plow and includes A multi-part planer strut 10 symmetrically formed with respect to the direction of travel of the tow hook plow 1, which has two outer struts 11 and a middle strut 12, the plow 1 is The machine strut 10 is guided on a non-illustrated face conveyor, which can in particular be designed as a chain-type scraper conveyor. The plow body 2 for separating the ore to be mined, such as coal in particular, at the working face comprises a central plow base body 3 and two lateral tool holders 5, said plow base body being rigidly fixed, in particular welded to the central support plate 12 and is provided with a height-adjustable jacking frame 4, the tool rests 5 on the two sides are respectively swingably hinged on the planer base 3, and the two tool rests pass through accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com