Marine bioactive peptide with remarkable skin sunburn protection effect as well as preparation method and application of marine bioactive peptide

A technology of marine organisms and active peptides, applied in the field of biomedicine, can solve problems such as difficult large-scale industrial production and application, low yield of active peptides, and complicated preparation methods, achieving short production cycles, simple preparation processes, and good physiological effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

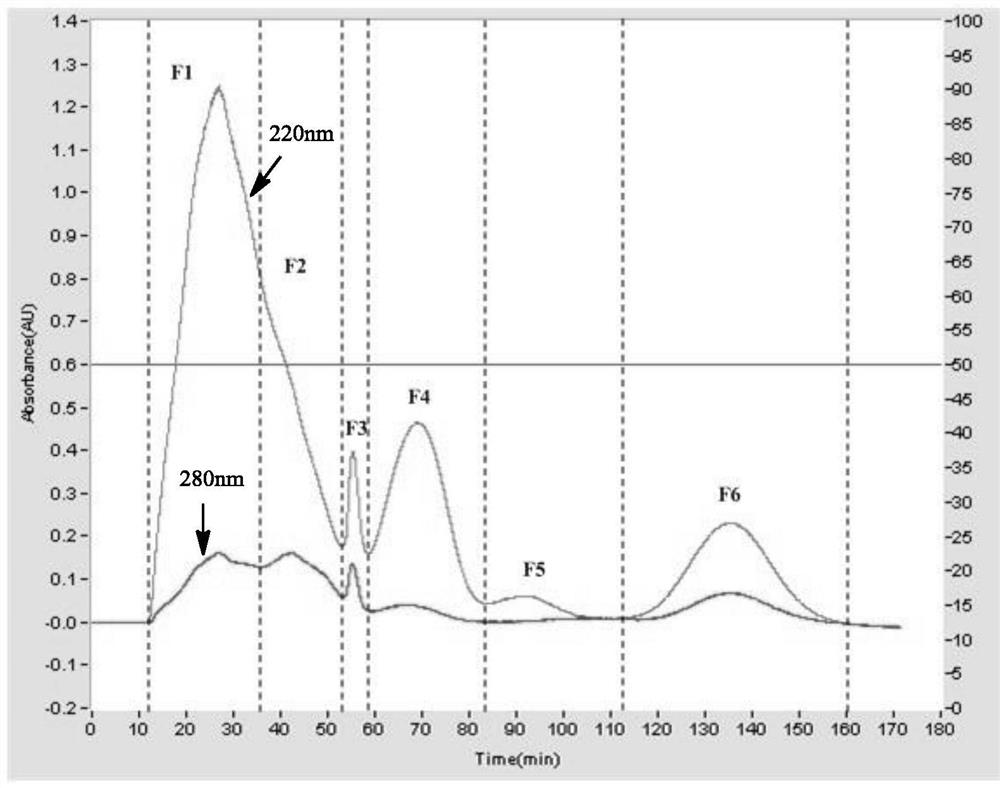

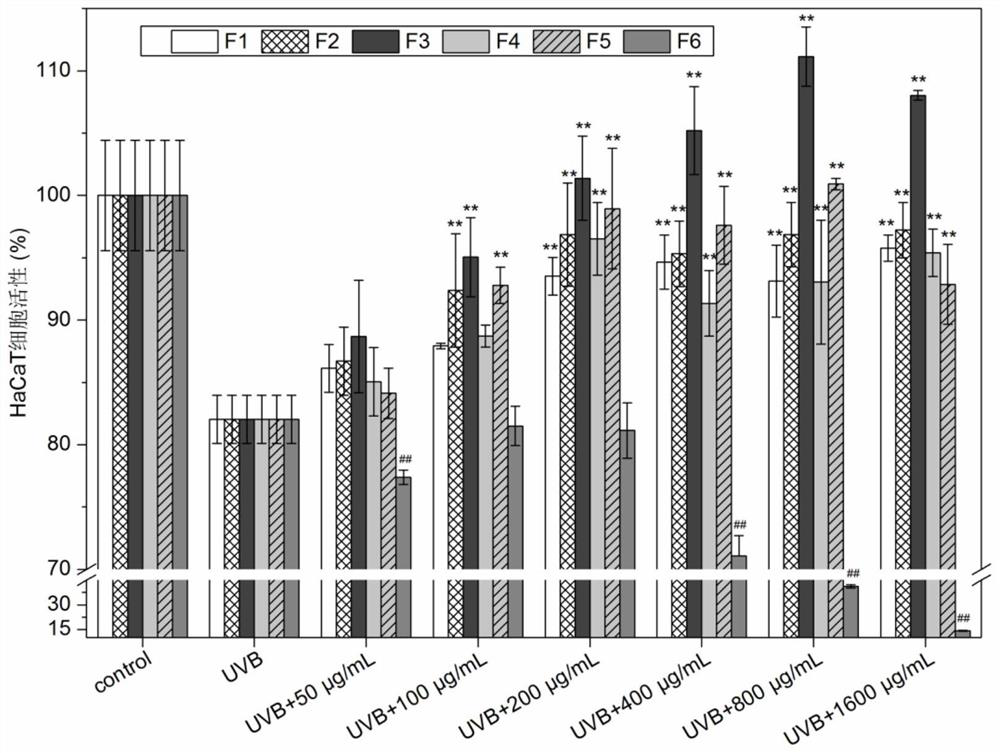

[0065] Take fresh and live clam scallops that meet the standards for the use of relevant seafood in my country, remove the shell, homogenize the soft body, add 4 times the volume of PBS buffer (0.01M, pH8.0), add trypsin (4000U / g shellfish), Enzymolysis was performed at a temperature of 37°C for 5 hours. The enzymolysis solution was boiled for 10 minutes and centrifuged at 10000×g for 10 minutes. The supernatant was ultrafiltered sequentially through ultrafiltration membranes with a molecular weight cut-off of 10 kDa and 3 kDa. Among them, the 3kDa-10kDa active peptide component is recorded as T1, and the active peptide component less than 3kDa is recorded as T2. Concentrate the T1 and T2 components to a concentration of about 200mg / mL, and then separate them with Sephadex G-15 (100×4.0cm): the sample volume is 8mL, the mobile phase is distilled water, the flow rate is 10mL / min, and the detection wavelength 220nm, 280nm.

[0066] The T1 (3kDa-10kDa) fraction was separated by...

Embodiment 2

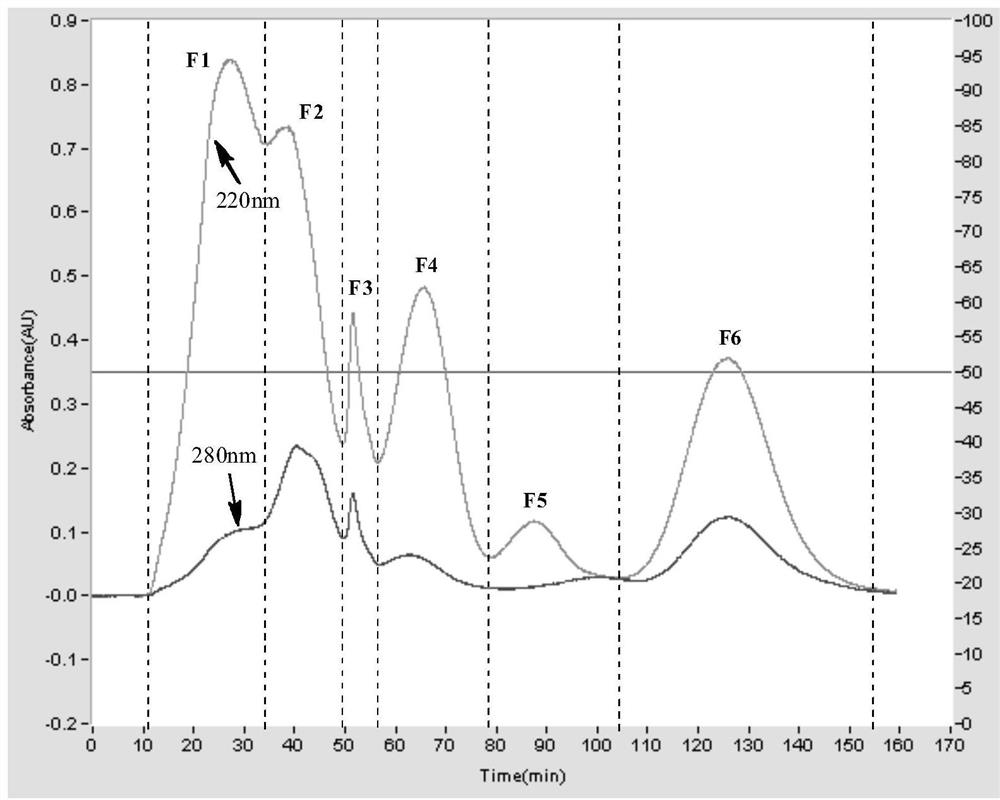

[0072] Take fresh and live clam scallops that meet the standards for the use of relevant seafood in my country, remove the shell, homogenize the soft body, add 3 times the volume of deionized water, adjust the pH value to 7.5, add trypsin (3000U / g shellfish), and the temperature is 40 ℃, enzymatic hydrolysis for 4h. The enzymolysis solution was boiled for 10 minutes and centrifuged at 8000×g for 12 minutes. The supernatant was ultrafiltered sequentially through ultrafiltration membranes with a molecular weight cut-off of 10 kDa and 3 kDa. Among them, the 3kDa-10kDa active peptide component is recorded as T1, and the active peptide component less than 3kDa is recorded as T2. Concentrate the T1 and T2 components to a concentration of about 100mg / mL, and then separate them with Sephadex G-15 (100×4.0cm): the loading volume is 10mL, the mobile phase is distilled water, the flow rate is 10mL / min, and the detection wavelength 220nm, 280nm.

[0073] Separate the T1 (3kDa-10kDa) fra...

Embodiment 3

[0078] Take fresh and live clam scallops that meet the standards for the use of relevant seafood in my country, remove the shells, take the soft part of the homogenate, add 2 times the volume of distilled water, adjust the pH value to 7, add trypsin (2000U / g shellfish), and heat at a temperature of 50 ° C. , Enzymolysis 6h. The enzymolysis solution was boiled for 10 minutes and centrifuged at 6000×g for 15 minutes. The supernatant was ultrafiltered through an ultrafiltration membrane with a molecular weight cut-off of 10 kDa, and the fraction of the filtrate (active peptide less than 10 kDa) was recorded as T. Concentrate the T component to a concentration of about 150mg / mL, and then separate it with Sephadex G-15 (100×4.0cm): sample volume is 12mL, mobile phase is distilled water, flow rate is 10mL / min, detection wavelength is 220nm, 280nm .

[0079] After the T (less than 10kDa) fraction is separated by Sephadex G-15, the first to sixth elution peak fractions are collected se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com