Preparation method of carbon quantum dot-carbon nanotube composite material with high adsorption performance

A technology of carbon quantum dots and carbon nanotubes, which is applied in the field of carbon quantum dots-carbon nanotube composite materials, can solve problems such as cumbersome steps, unfavorable environmental protection, and use restrictions, and achieve the avoidance of modification treatment, important environmental protection significance, good The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

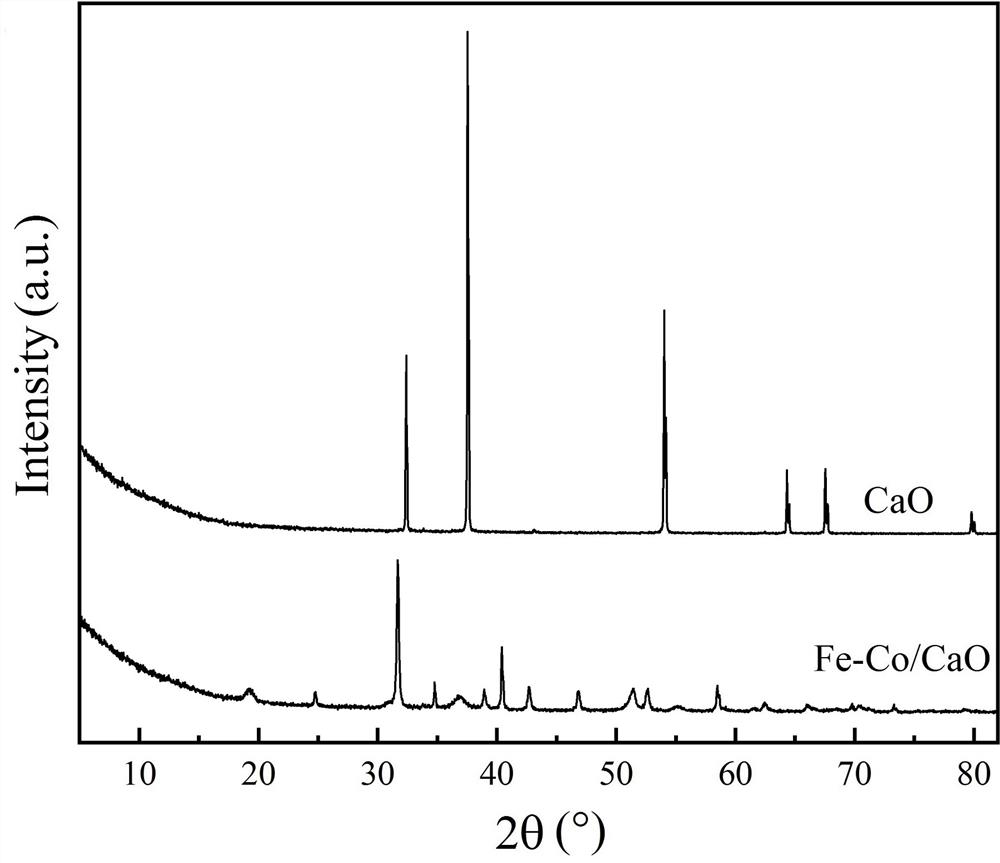

[0041] (1) Preparation of the catalyst: Calcinate the washed and dried calcium-based waste such as eggshells at 900°C for 4 hours to obtain the CaO carrier; add the weighed cobalt(II) acetylacetonate and iron(III) acetylacetonate In 100mL of absolute ethanol, stir at 60°C to completely dissolve the metal salt; then add the calcined CaO carrier into the above metal salt solution, stir at room temperature for 30min; then raise the temperature to 60°C and stir until viscous °C oven dried overnight; finally the dried catalyst was ground and calcined at 450 °C for 3 h. The molar ratio of iron to cobalt in the catalyst prepared by the above steps is 1:1, and the total metal content supported by the CaO carrier is 5 wt%.

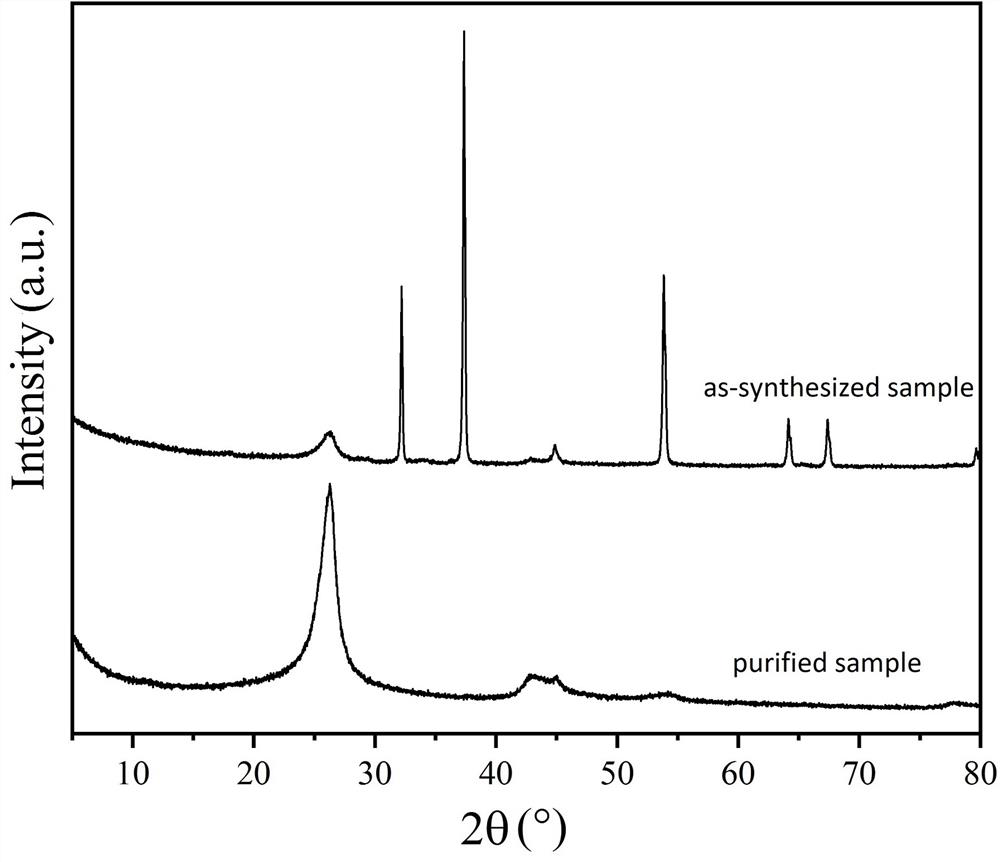

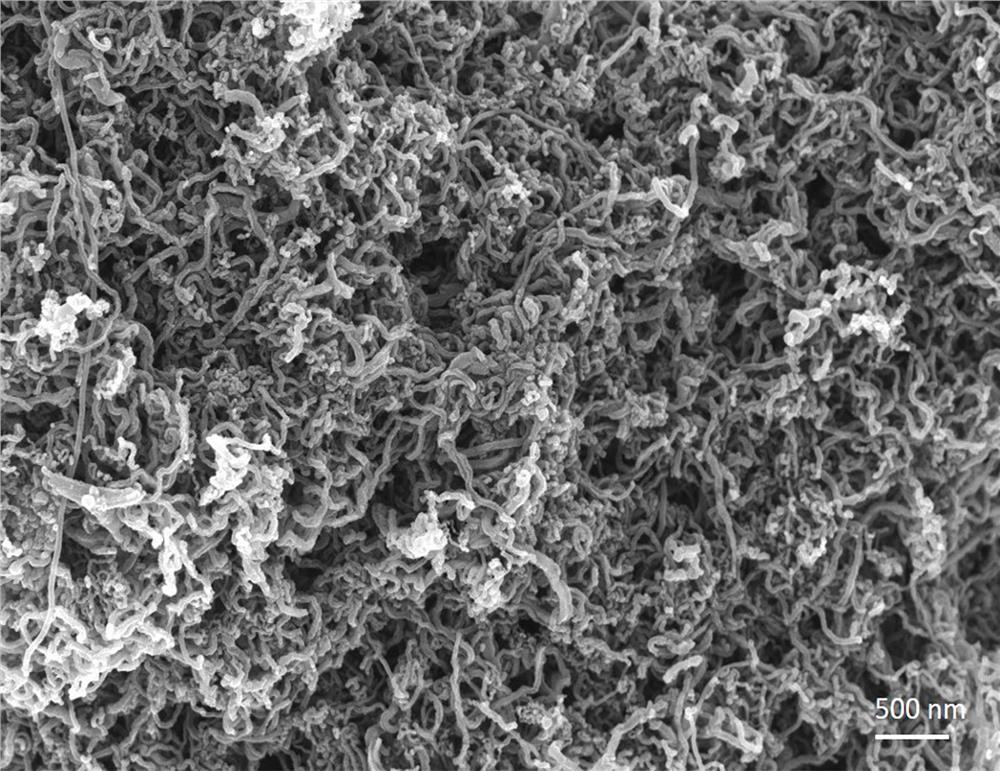

[0042] (2) Synthesis of carbon quantum dots-carbon nanotubes: take by weighing 150 mg of the catalyst prepared in the above step (1), lay it evenly in the porcelain boat, then put the porcelain boat into the tube furnace; The hydrogen gas is 30 sccm, and the tempe...

Embodiment 2

[0047] (1) Preparation of catalyst: The preparation of catalyst in this embodiment is the same as in Example 1.

[0048] (2) Synthesis of carbon quantum dots-carbon nanotubes: take by weighing 150 mg of the catalyst prepared in the above step (1), lay it evenly in the porcelain boat, then put the porcelain boat into the tube furnace; 30sccm of hydrogen, the temperature is raised to 700°C at a heating rate of 10°C / min, then the hydrogen is adjusted to argon, and the temperature continues to rise in an argon atmosphere; when the temperature rises to 850°C, purge the The ethanol vapor was brought into the reaction zone in the tube furnace and reacted for 30 minutes; after the reaction, the ethanol was stopped and the temperature was lowered to room temperature in an argon atmosphere to obtain a carbon quantum dot-carbon nanotube composite material.

[0049] (3) Purification of carbon quantum dots-carbon nanotubes: the purification of the composite material in this example is the ...

Embodiment 3

[0053] (1) Preparation of catalyst: The preparation of catalyst in this embodiment is the same as in Example 1.

[0054] (2) Synthesis of carbon quantum dots-carbon nanotubes: take by weighing 150 mg of the catalyst prepared in the above step (1), lay it evenly in the porcelain boat, then put the porcelain boat into the tube furnace; It is 30 sccm of hydrogen, and the temperature is raised to 700 °C at a heating rate of 10 °C / min, and then the hydrogen is adjusted to argon, and the temperature is continued in an argon atmosphere; The ethanol vapor was brought into the reaction zone in the tube furnace and reacted for 30 minutes; after the reaction, the ethanol was stopped and the temperature was lowered to room temperature in an argon atmosphere to obtain a carbon quantum dot-carbon nanotube composite material.

[0055] (3) Purification of carbon quantum dots-carbon nanotubes: the purification of the composite material in this example is the same as in Example 1.

[0056] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com