Involute helical surface inner meshing line contact conjugate surface analysis method and curved surface tooth cutting tool

An analytical method and helical surface technology, applied in the direction of gear tooth manufacturing tools, gear teeth, manufacturing tools, etc., can solve the problems of non-continuous smoothness, slow solution speed, unfavorable tool and rapid design of abrasive tools, etc. The effect of stable calculation and easy engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

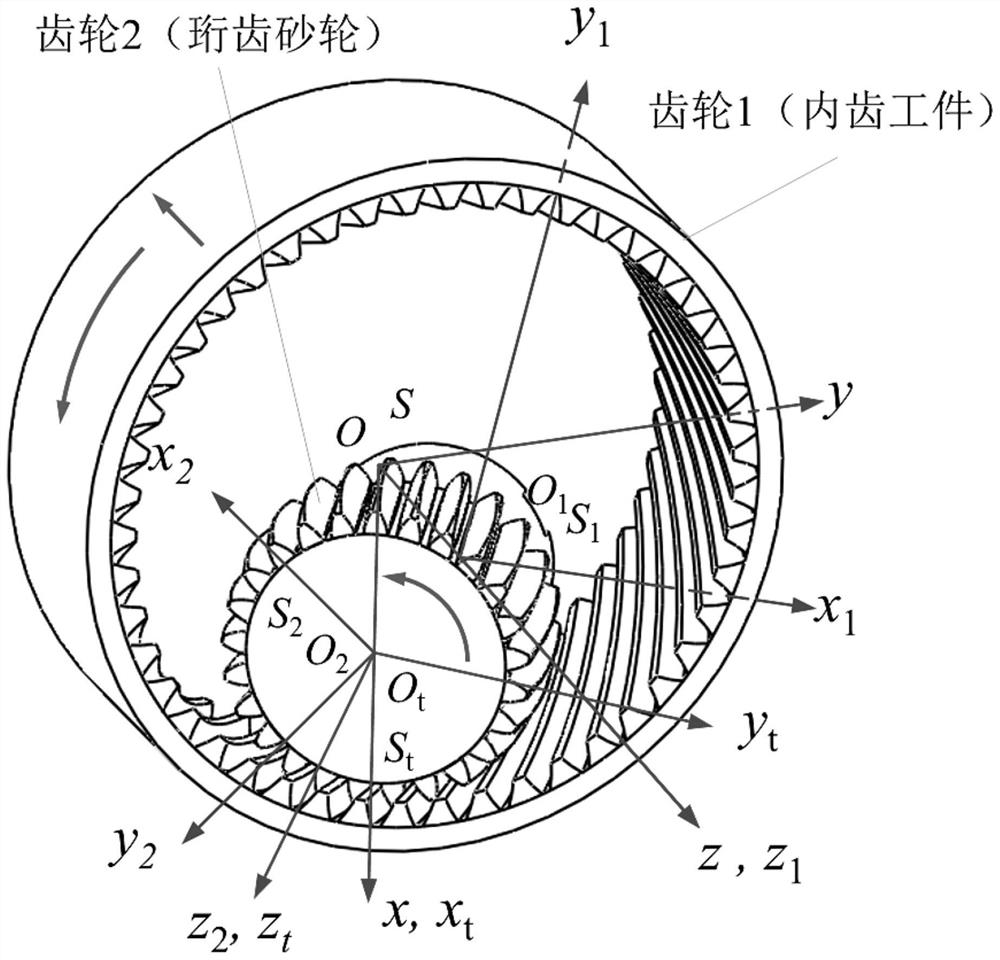

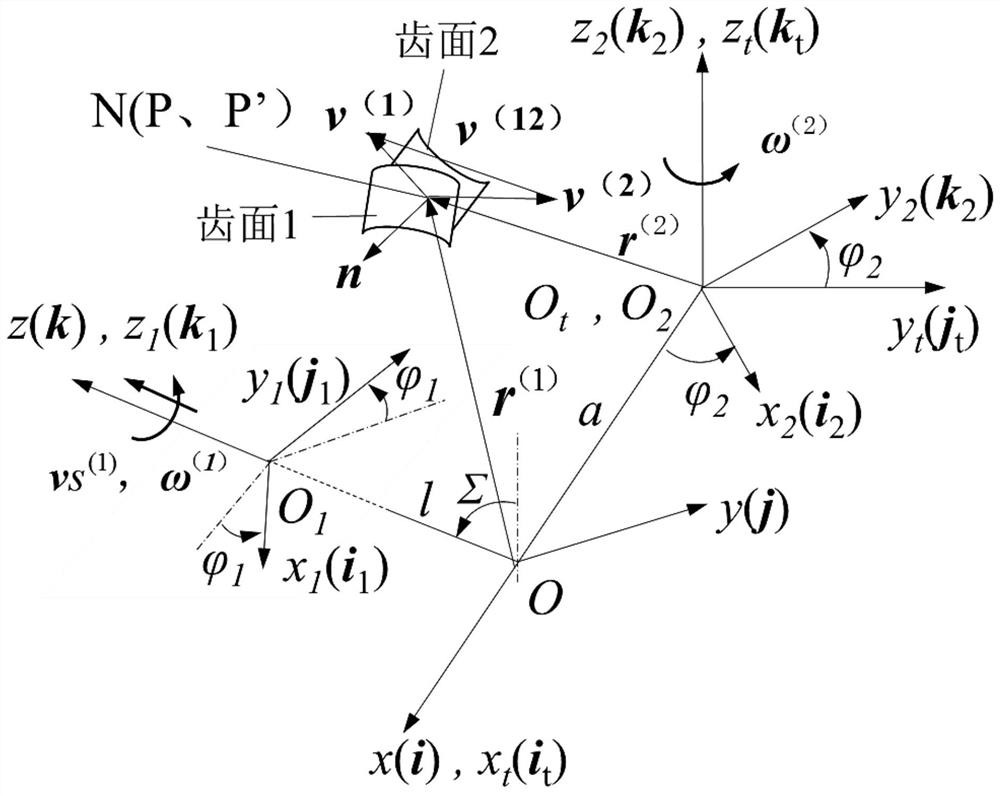

[0051] Analytical methods for contacting conjugate surfaces of meshing lines in involute helical surfaces, including:

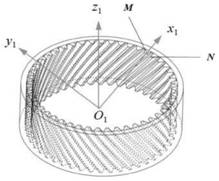

[0052] S1, determine that the object to be solved is two involute helical surfaces M and N on both sides of a tooth groove of the honing wheel, and establish a dynamic coordinate system S 1 (O 1 -x 1 the y 1 z 1 ),z 1 The shaft coincides with the axis of the internal tooth workpiece, plane O 1 x 1 the y 1 Parallel to the end face of the internal tooth workpiece, the distance between the end face and the end face is half of the tooth width, x 1 The axis passes through the center of the tooth space of the internal tooth workpiece, and the moving coordinate system S 1 Fixed connection with internal tooth workpiece;

[0053] S2, obtain the initial required parameters r for solving the involute helicoids M and N respectively b , σ 0 , θ, u, p, among them, r b is the radius of the involute base circle, σ 0 Indicates the starting position of the involut...

Embodiment 2

[0185] Compared with Embodiment 1, the only difference is that it also includes a clamping power supply device, an AD conversion module and a processing module (in this embodiment, the processing module is a stc12c5a60s2 single-chip microcomputer, which has a 16-bit AD conversion module. The accuracy can reach 5 / 255V. After testing, it has been able to detect the deformed tool. If you want to improve the accuracy, you can choose an AD conversion module with higher accuracy). And the circle defined by the center of the circle and the inner diameter is the upper inner diameter circle; the lower inner diameter circle is defined similarly, the surfaces of the upper inner diameter circle and the lower inner diameter circle are covered with an insulating film, and the clamping power supply device is clamped between the upper end surface and the lower inner diameter circle. On both sides of the end face, the clamping power supply device is in close contact with the upper end face and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com