Method for preparing metal particle-loaded coal-based graphene through high-temperature thermal shock

A metal particle and graphene technology, which is applied in the field of high-temperature thermal shock preparation of coal-based graphene-loaded metal particles, can solve the problems of high energy consumption, long reaction time, and high cost of solvothermal reaction, and achieve rapid response, low cost, and The effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] High-temperature thermal shock of coal-based graphene supported metal Ni under different discharge voltages:

[0028] Step 1) preparation takes by weighing excessive nickel chloride hexahydrate NiCl with analytical balance 2 · 6 h 2 O, 20g dissolved in a small amount of water H 2 O, 5mL, prepare supersaturated NiCl 2 aqueous solution;

[0029] Step 2) Add 200 mesh 1g coal tar pitch, mix the solution evenly, let stand, filter and dry to obtain conductive NiCl 2 @Coal tar pitch precursor;

[0030] Step 3) Accurately weigh 120mg of dried and processed NiCl 2 @Coal tar pitch precursor, put the sample in a quartz tube with an inner diameter of 6mm, and fix the loaded quartz tube at both ends of the capacitor electrode;

[0031] Step 4) Set inert gas protection, vacuumize the reaction chamber with a vacuum pump and fill it with nitrogen, repeat three times to replace the oxygen in the reaction chamber to ensure that the materials are not oxidized during the reaction. ...

Embodiment 2

[0035] High-temperature thermal shock of metal Ni supported on coal-based graphene under different discharge times:

[0036] Step 1)-4) with embodiment 1;

[0037] Step 5) Apply high voltage, choose capacitor 60mF, choose voltage 200V, power-on time is 50ms, 100ms, 150ms, 200ms, 300ms, sieve the coal-based graphene material that is less than 200 meshes and load metal nanoparticles.

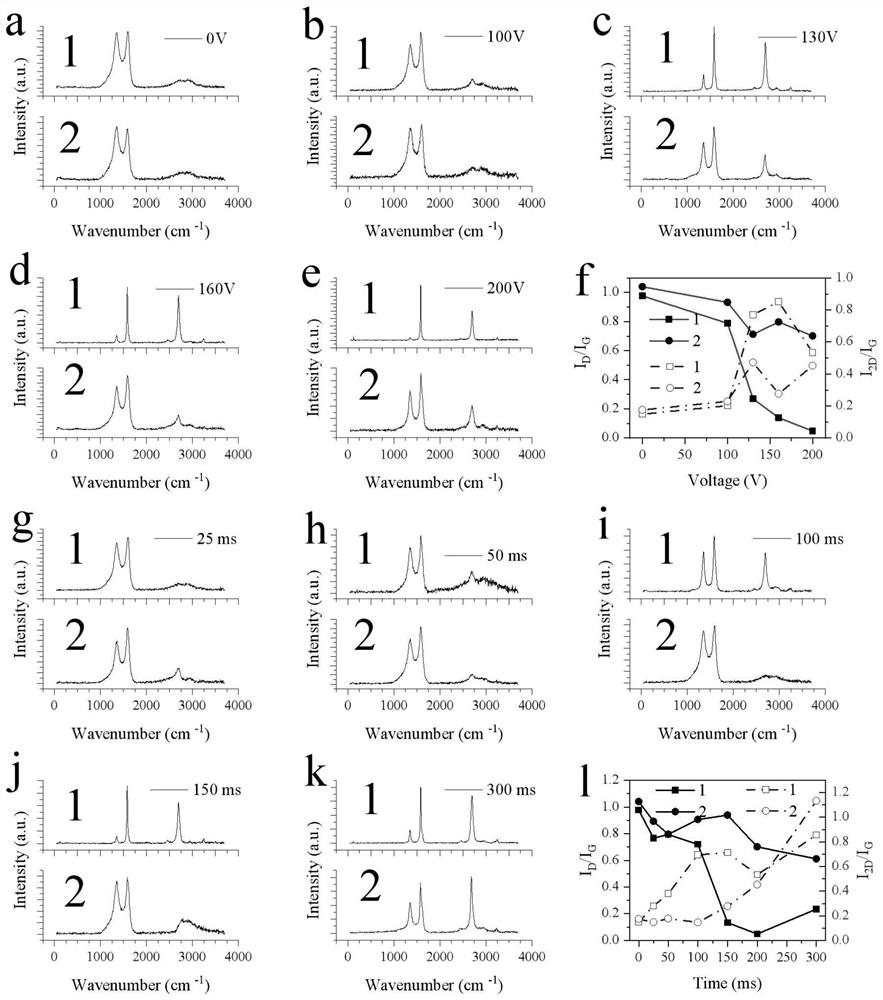

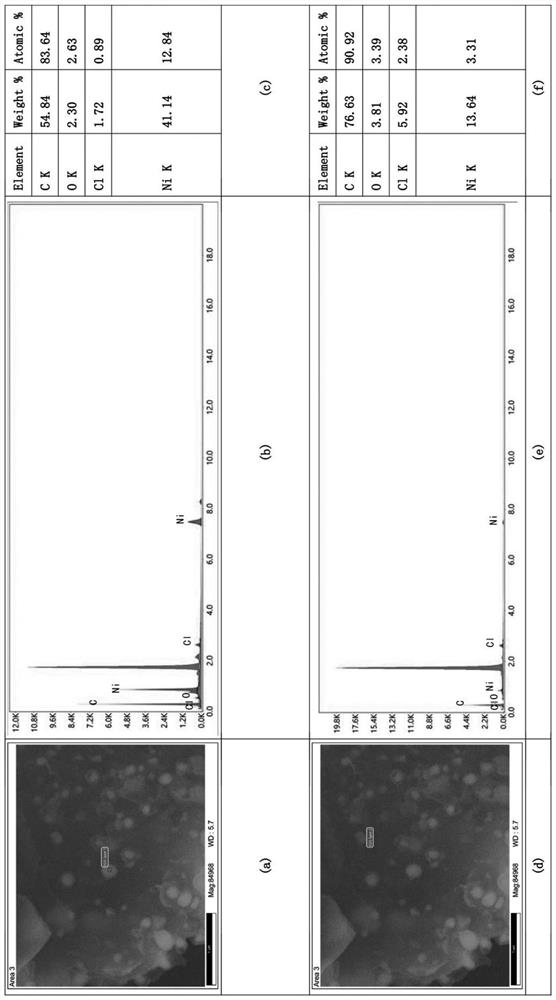

[0038] like figure 1 Shown is a comparison chart of Raman spectra of coal-based graphene loaded with metal Ni nanoparticles before and after high temperature thermal shock in Examples 1 and 2. Among them, (a) is NiCl before flashing 2 @The Raman spectrum of the coal tar pitch precursor, (b)-(e) is the comparison figure of the Raman spectrum of the coal-based graphene loaded with metal Ni nanoparticles after different voltage treatments in Example 1, (f) is different Voltage I D / I G and I 2D / I G The ratio of; (g)-(k) is the contrast figure of the Raman spectrum of the coal-based graphene o...

Embodiment 3

[0042] High-temperature thermal shock of coal-based graphene-supported metal Co:

[0043] Step 1) preparation takes by weighing excessive cobalt chloride hexahydrate CoCl with analytical balance 2 · 6 h 2 O, 20g dissolved in a small amount of water H 2 O, 5mL, prepare supersaturated CoCl 2 aqueous solution;

[0044] Step 2-4 is with embodiment 1;

[0045] Step 5) Apply a high voltage, select a capacitor of 60mF, select a voltage of 200V, and a power-on time of 200ms, and sieve out a coal-based graphene material with a mesh size of less than 200 to obtain metal nanoparticles.

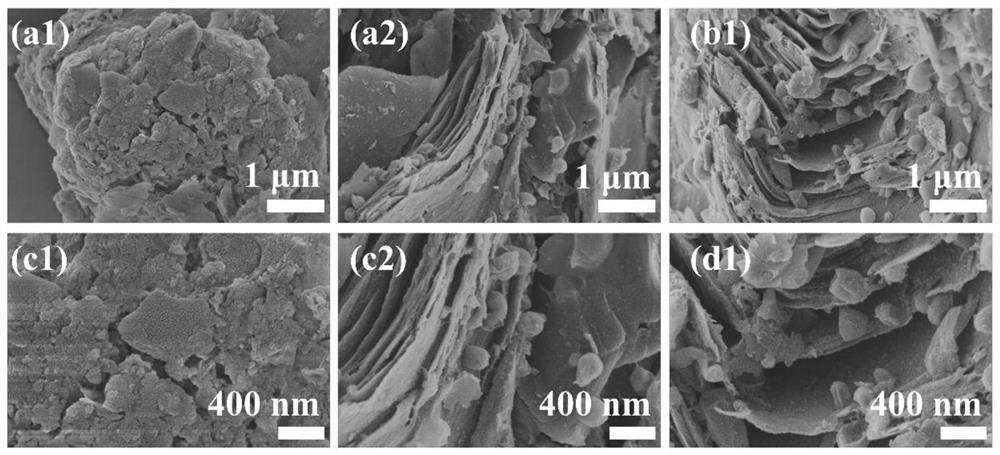

[0046] like Figure 4 Shown is the scanning electron microscope image of the coal-based graphene loaded with metal Co nanoparticles after high temperature thermal shock in Example 3. It can be seen from the figure that the metal Co particles are successfully loaded on the graphite sheet after high temperature thermal shock.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com