Automatic wood chip collecting and forming device for furniture wood processing

An automatic collection and forming device technology, applied in wood processing equipment, special forming/shaping machines, forming/shaping machines, etc., can solve problems such as non-conforming to energy saving and environmental protection, wood chips are flammable, and increase the risk of wooden furniture, etc., to achieve Improve safety, energy saving and environmental protection, efficient cutting and processing, and improve the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

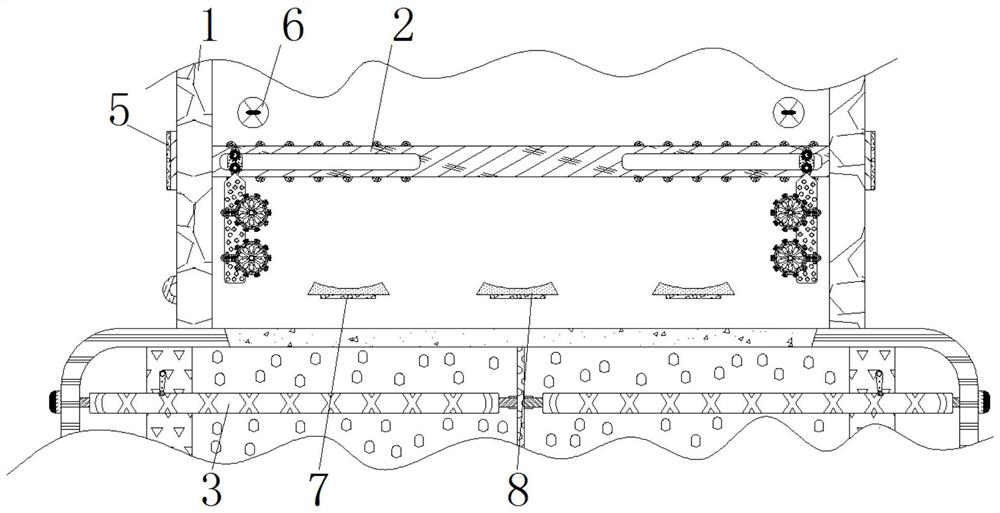

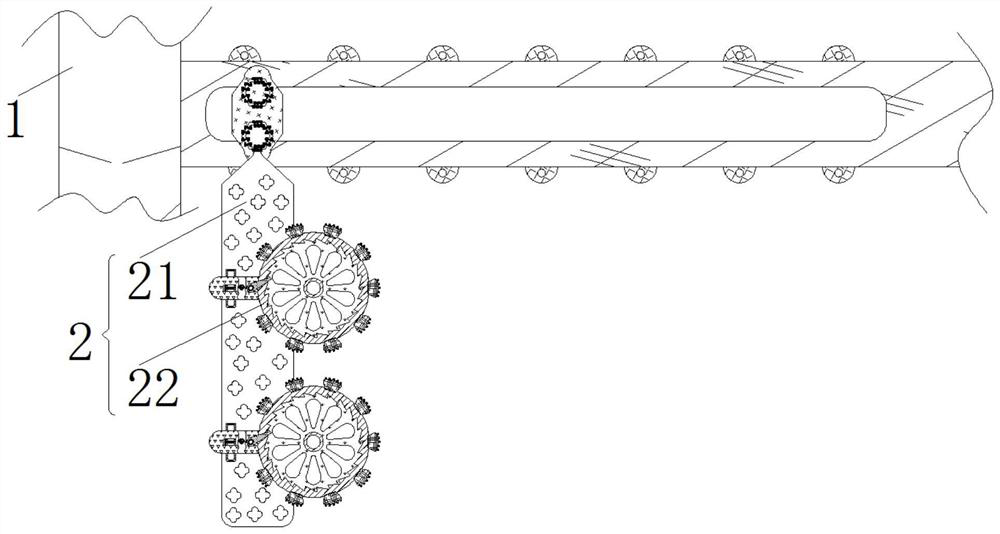

[0028] see Figure 1-7 , a sawdust automatic collection and molding device for furniture wood processing, comprising a casing 1, a processing mechanism 2 is movably connected to the inside of the casing 1, and the processing mechanism 2 includes a moving assembly 21 for adjusting the processing distance, a cutting device for wood processing Assemblies 22 , the moving assembly 21 is movably connected inside the housing 1 , and the cutting assembly 22 is movably connected outside the moving assembly 21 .

[0029] The moving assembly 21 includes a receiving plate 211, a magnetic ring 212, a chute 213, an electromagnet 214, and a support plate 215. The receiving plate 211 is fixedly connected to the inside of the housing 1, the magnetic ring 212 is fixedly connected to the outside of the receiving plate 211, and the chute 213 Opened on the surface of the receiving plate 211 , the electromagnet 214 is slidably connected to the inner side of the chute 213 , and the support plate 215...

Embodiment 2

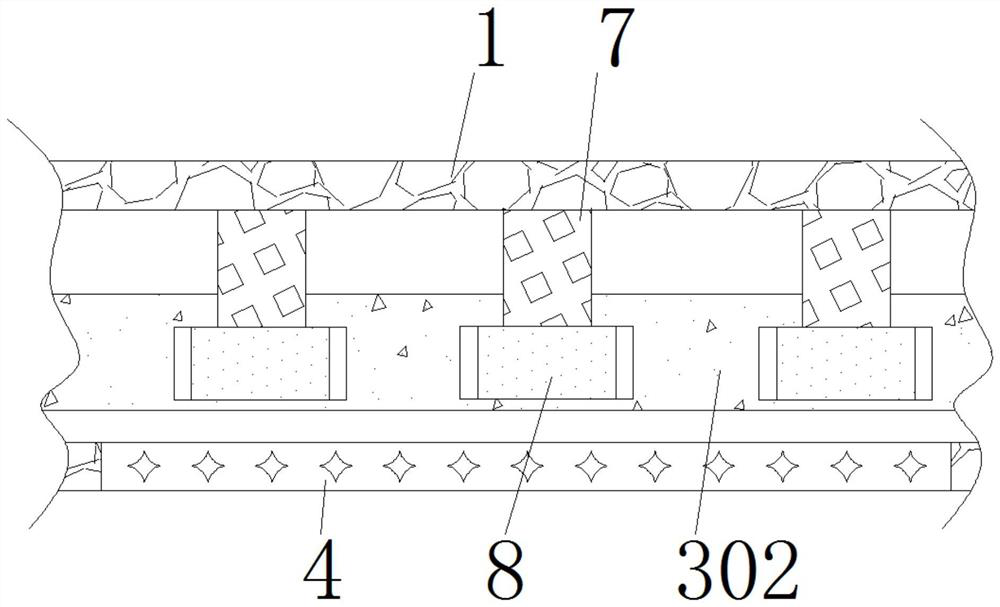

[0033] see Figure 8-9 , an automatic wood chip collection and molding device for furniture wood processing, comprising a casing 1, a processing mechanism 2 is movably connected to the inside of the casing 1, and the processing mechanism 2 includes a moving assembly 21 for adjusting the processing distance, and a cutting assembly 22 for wood processing , the moving assembly 21 is movably connected inside the housing 1 , and the cutting assembly 22 is movably connected outside the moving assembly 21 .

[0034]The outer casing 1 is movably connected with a molding mechanism 3, and the molding mechanism 3 includes a collecting shell 301, an inlet 302, a second motor 303, a screw mandrel 304, a reciprocating block 305, a connecting rod 306, and an extruding plate 307, and the collecting shell 301 is fixedly connected to the Outside the shell 1, the entrance 302 is opened on the surface of the collection case 301, the second motor 303 is fixedly connected to the outside of the coll...

Embodiment 3

[0037] see Figure 1-9 , an automatic wood chip collection and molding device for furniture wood processing, comprising a casing 1, a processing mechanism 2 is movably connected to the inside of the casing 1, and the processing mechanism 2 includes a moving assembly 21 for adjusting the processing distance, and a cutting assembly 22 for wood processing , the moving assembly 21 is movably connected inside the housing 1 , and the cutting assembly 22 is movably connected outside the moving assembly 21 .

[0038] The moving assembly 21 includes a receiving plate 211, a magnetic ring 212, a chute 213, an electromagnet 214, and a support plate 215. The receiving plate 211 is fixedly connected to the inside of the housing 1, the magnetic ring 212 is fixedly connected to the outside of the receiving plate 211, and the chute 213 Opened on the surface of the receiving plate 211 , the electromagnet 214 is slidably connected to the inner side of the chute 213 , and the support plate 215 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com