A multifunctional robot for flexible intelligent manufacturing of sheet metal

An intelligent manufacturing and multi-functional technology, applied in the field of sheet metal manufacturing, can solve the problems of low efficiency of sheet metal manufacturing, achieve the effect of avoiding low-efficiency manual handling, facilitating efficient cutting and processing, and improving processing and manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

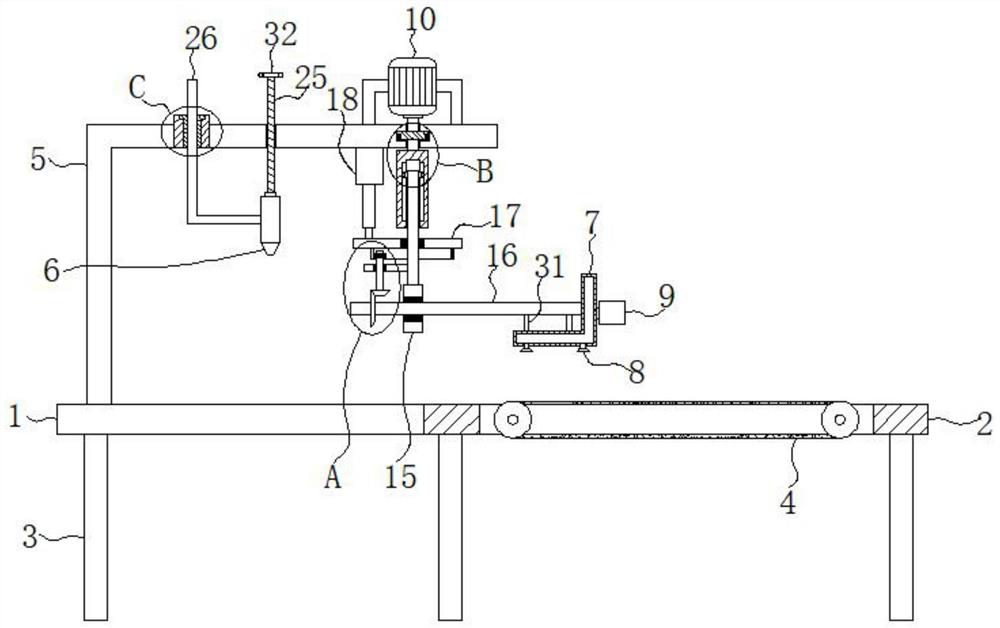

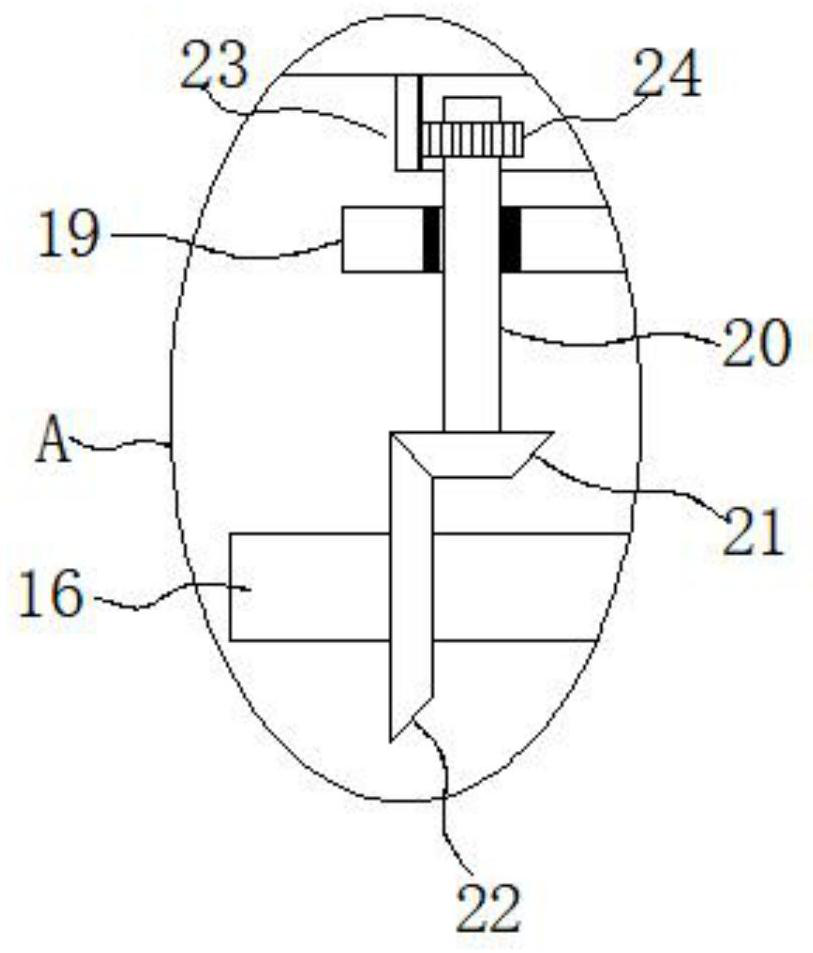

[0028] see Figure 1-3 , a multi-functional robot for flexible intelligent manufacturing of sheet metal, including a processing table 1 and a frame 2 that are flush with each other, the processing table 1 and the frame 2 are fixedly connected, and the bottoms of the processing table 1 and the frame 2 are fixedly connected with supporting legs 3. A matching conveyor belt 4 is installed in the frame 2, an L-shaped column 5 is fixedly connected to the upper surface of the processing table 1 away from the frame 2, and the horizontal part of the L-shaped column 5 is connected with a laser cutting head 6 through a regulating mechanism. The conveyor belt 4 An L-shaped hollow plate 7 is arranged above the L-shaped hollow plate 7, and the L-shaped hollow plate 7 and the L-shaped column 5 are connected by a lifting and shifting rotation mechanism. The vertical part of the hollow plate 7 is fixedly installed with a vacuum generator 9, and the input end of the vacuum generator 9 is in fix...

Embodiment 2

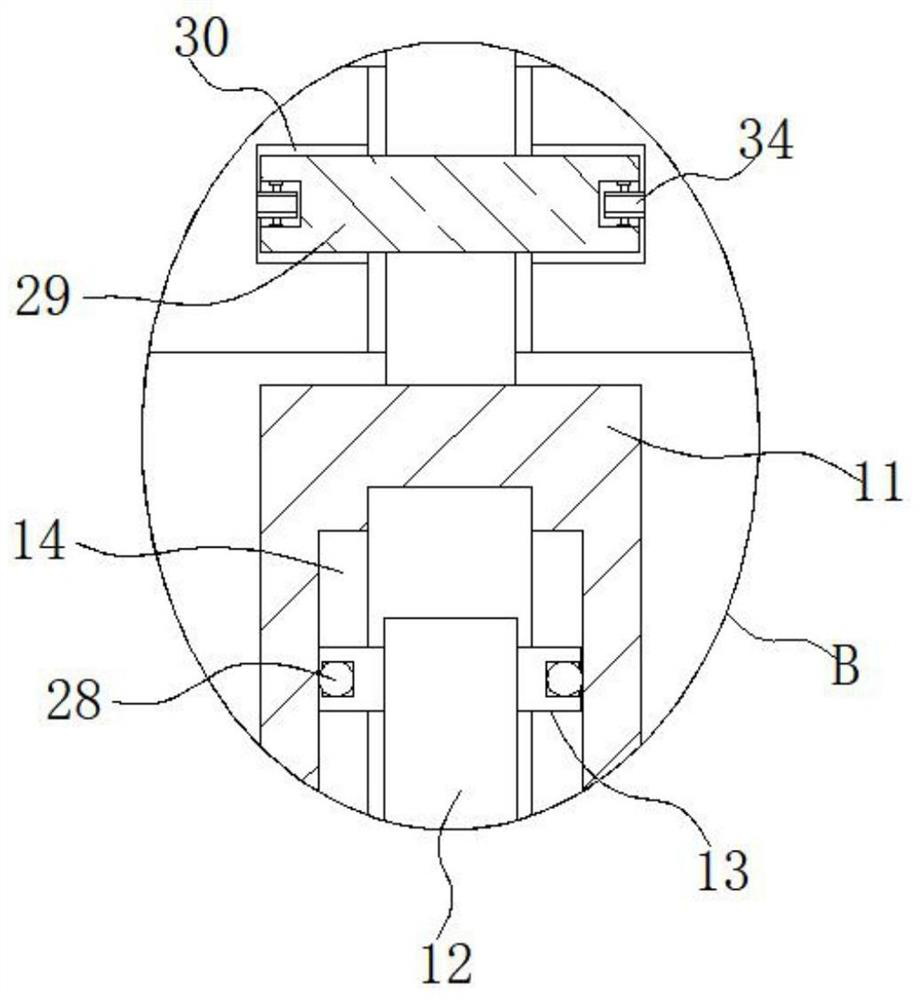

[0036] refer to figure 1 and Figure 4 , a multi-functional robot for flexible intelligent manufacturing of sheet metal, including a processing table 1 and a frame 2 that are flush with each other, the processing table 1 and the frame 2 are fixedly connected, and the bottoms of the processing table 1 and the frame 2 are fixedly connected with supporting legs 3. A matching conveyor belt 4 is installed in the frame 2, an L-shaped column 5 is fixedly connected to the upper surface of the processing table 1 away from the frame 2, and the horizontal part of the L-shaped column 5 is connected with a laser cutting head 6 through a regulating mechanism. The conveyor belt 4 An L-shaped hollow plate 7 is arranged above the L-shaped hollow plate 7, and the L-shaped hollow plate 7 and the L-shaped column 5 are connected by a lifting and shifting rotation mechanism. The vertical part of the hollow plate 7 is fixedly installed with a vacuum generator 9, and the input end of the vacuum gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com