Robotic system for cutting soft materials

A robot system and soft material technology, applied in the field of soft material processing, can solve problems such as low work efficiency, and achieve the effects of stable operation, high-efficiency cutting and processing, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

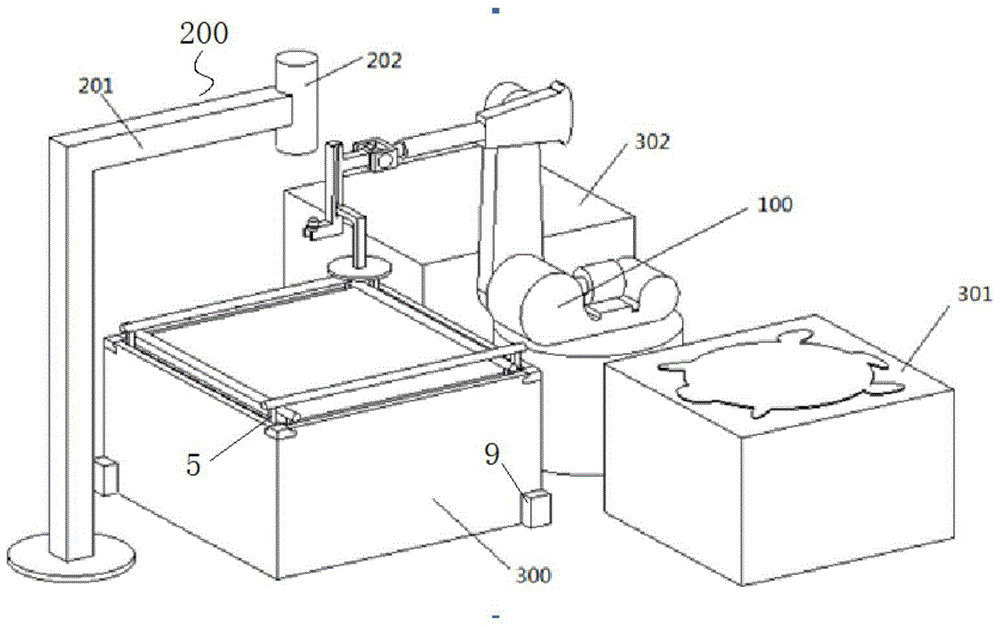

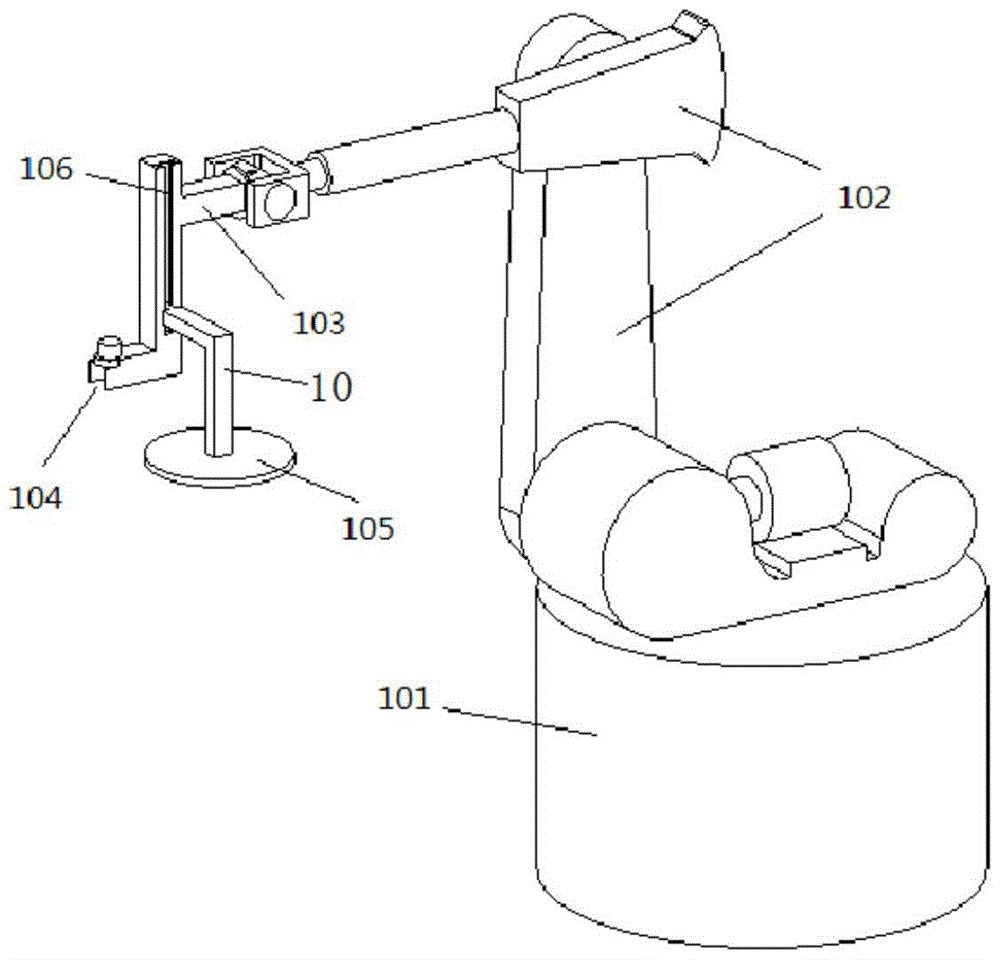

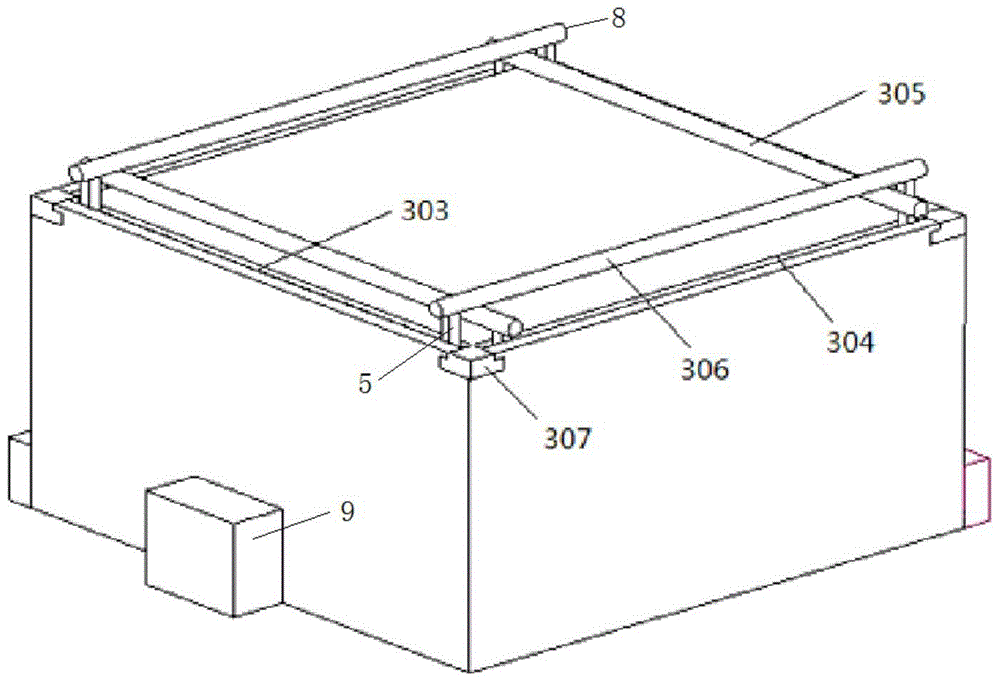

[0026] Such as Figure 1-Figure 5 As shown, the structure schematic diagram of the present invention, the present invention is used to automatically transport, pave, identify and cut soft materials to be cut, including a 6-degree-of-freedom articulated arm responsible for grasping, cutting and placing soft materials The robot 100 includes a base 101, a mechanical arm 102 installed on the base 101 and an end effector 103 installed on the mechanical arm 102; the end effector 103 includes a lifting guide rail 106, and a cutting water gun 104 is installed at the bottom of the lifting guide rail 106 , there are metal plates on both sides and rear of the cutting water gun 104 for resisting the cutting fluid, and the lifting guide rail 106 is slidably installed with a suction cup 105 through the connecting arm 10;

[0027] An image recognition device 200 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com