Device and method for preparing liquid metal catalyst by plasma

A liquid metal and catalyst technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of low gas-liquid mass transfer efficiency and achieve rapid preparation, The effect of increasing yield and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

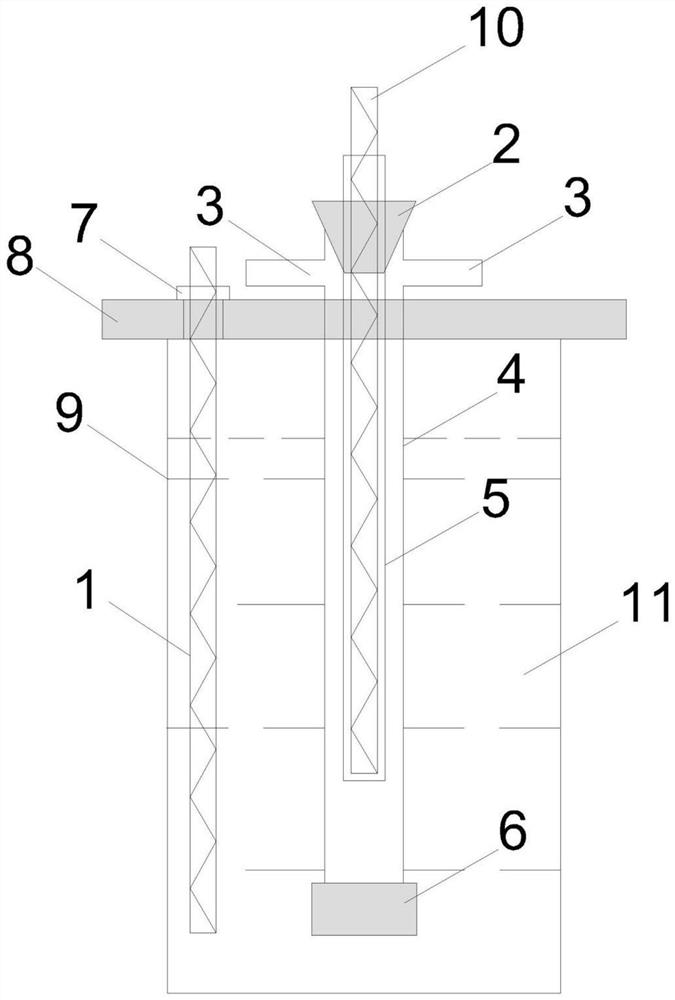

Method used

Image

Examples

Embodiment 1

[0032] Example 1, dissolve oxalic acid and nickel nitrate with a molar ratio of 1:1 in water, and use potassium carbonate to adjust the pH value of the solution to 10 as the reaction solution for preparing the catalyst, discharge it with an AC source, pass oxygen during the discharge process, and the oxygen flow rate is 200mL / min. When the discharge voltage is 5kV, the discharge frequency is 3kHz, and the discharge time is 20min, the solution can be clearly separated into layers, and an oil-soluble nickel oxalate catalyst and a water-soluble catalyst rich in active oxygen components can be obtained respectively. The obtained oil-soluble and water-soluble catalysts were used in the catalytic upgrading of heavy oil at a volume ratio of 3:1, where the viscosity of the heavy oil at 20°C was 2016.66 mPa·s. The experimental results show that when the reaction temperature is 290°C and the reaction time is 24 hours, the viscosity of the heavy oil is 403.33mPa·s, the viscosity reducti...

Embodiment 2

[0033] Example 2, dissolving ammonium heptamolybdate and nickel nitrate with a molar ratio of 1:7 in water, adding oleic acid and using ammonium hydroxide to adjust the pH value of the solution to 8 as the reaction solution for preparing the catalyst, discharging with a pulse source, during the discharge process Ventilate the air, the air flow rate is 500mL / min. When the peak voltage is 25kV, the discharge frequency is 5kHz, the pulse width is 10μs, and the discharge time is 15min, a nickel molybdate bimetallic catalyst rich in active oxygen components can be obtained. The prepared catalyst is used in the catalytic upgrading of heavy oil. The experimental results show that the reaction temperature is 290°C, the reaction time is 24 hours, the viscosity reduction rate reaches 90%, and the API degree increases by 5.2.

Embodiment 3

[0034] Embodiment three, adopt 1mol / L silver nitrate solution, control pH value to be 7, discharge with direct current source, open 8 micropores that diameter is 0.5mm in aeration pipe, and prepare liquid state with the hydrogen of flow rate 150mL / min as carrier gas nanosilver catalyst. When the discharge voltage is 2kV and the discharge time is 30min, the nano-silver catalyst with a particle size of 5-30nm can be obtained.

[0035] The invention adopts the plasma method to prepare the liquid metal catalyst. Compared with the traditional catalyst preparation method, it is more rapid, uniform and efficient, and the catalyst can be produced in a large amount in only tens of minutes; The introduction into the liquid catalyst increases the activity of the catalyst; in addition, the preparation temperature of the catalyst can be effectively controlled by adjusting the discharge parameters. The catalyst prepared by this method has strong practical value and application prospect in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com