Photocatalyst with function of releasing negative oxygen ions, and preparation method and application thereof

A photocatalyst and negative oxygen ion technology, applied in the field of photocatalytic materials, can solve the problems of easy sintering, uneven distribution, affecting catalytic activity and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

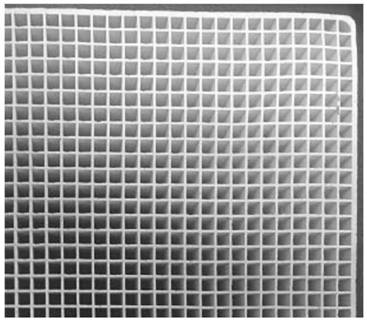

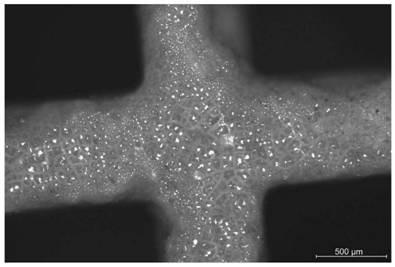

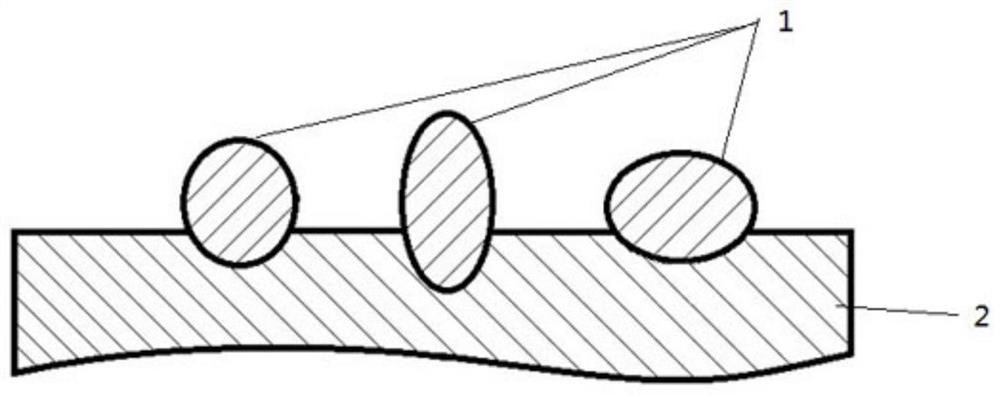

[0082] Mix nano-titanium dioxide (particle size below 100nm, the same below) with polyethylene glycol (molecular weight: 600), and then mix with pseudo-boehmite, nitric acid, and water, and then mix nano-titanium dioxide, pseudo-boehmite (with alumina ), nitric acid, and water are mixed in a weight ratio of 15:3:2:15, and the amount of polyethylene glycol added is added according to 3% of the weight of the mixed slurry of titanium dioxide and aluminum oxide to obtain a mixed slurry of titanium dioxide and aluminum oxide;

[0083] Spray the mixed slurry of titanium dioxide and alumina on cordierite honeycomb ceramics, perform unsaturated spray dipping according to 70% of the absorption rate, then dry at 70°C for 4 hours, bake at 280°C for 3 hours, and bake at 600°C 3 hours, obtain the honeycomb ceramic carrier A of loading modifying agent;

[0084] Immerse the honeycomb ceramic carrier A loaded with the modifier into titanium sol for vacuum impregnation, remove excess slurry, t...

Embodiment 2

[0089] Mix nano-titanium dioxide with polyethylene glycol (molecular weight: 600), and then mix with pseudo-boehmite, nitric acid, and water. Nano-titanium dioxide, pseudo-boehmite (based on alumina), nitric acid, and water The mixing ratio is 15:3.5:2:18, and the amount of polyethylene glycol is added according to 2.5% of the weight of the mixed slurry of titanium dioxide and aluminum oxide to obtain a mixed slurry of titanium dioxide and aluminum oxide;

[0090] Spray and impregnate the mixed slurry of titanium dioxide and alumina on the cordierite honeycomb ceramics, perform unsaturated spray impregnation according to 70% of the absorption rate, then dry at 70°C for 4 hours, bake at 260°C for 3 hours, and bake at 650°C 3 hours, obtain the honeycomb ceramic carrier B of loading modifying agent;

[0091] Immerse the modifier-loaded honeycomb ceramic carrier B in the titanium sol for vacuum impregnation, remove excess slurry, then dry at 70°C for 4 hours, repeat this step once...

Embodiment 3

[0096] Nano-titanium dioxide is mixed with polyethylene glycol (molecular weight is 400), and then mixed with pseudo-boehmite, nitric acid, and water, and nano-titanium dioxide, pseudo-boehmite (calculated as alumina), nitric acid, and water are mixed by weight The mixing ratio is 15:3.5:2:18, and the amount of polyethylene glycol is added according to 2.5% of the weight of the mixed slurry of titanium dioxide and aluminum oxide to obtain a mixed slurry of titanium dioxide and aluminum oxide;

[0097] Spray and impregnate the mixed slurry of titanium dioxide and alumina on the cordierite honeycomb ceramics, perform unsaturated spray impregnation according to 70% of the absorption rate, then dry at 70°C for 4 hours, bake at 250°C for 3 hours, and bake at 650°C 3 hours, obtain the honeycomb ceramic carrier C of loading modifying agent;

[0098] Immerse the honeycomb ceramic carrier C loaded with the modifier into the titanium sol for vacuum impregnation, remove excess slurry, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com