A kind of magnetic steel production equipment for motor

A technology for production equipment and magnets, which is applied in the field of magnets production equipment for motors, can solve the problems of temperature sensitivity of magnets, affecting the stability of magnetization and permeability of magnets, and reducing the quality of magnets, so as to reduce Effects of heating, reducing residual moisture, and increasing property stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

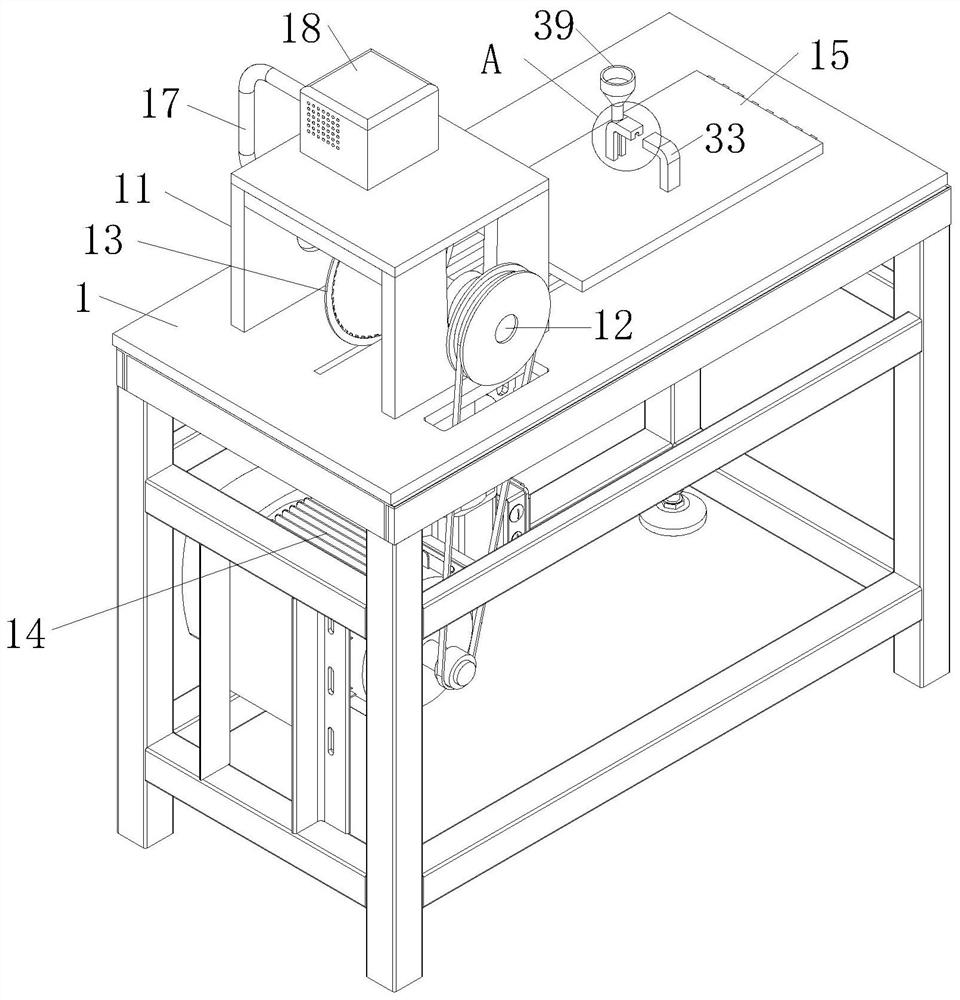

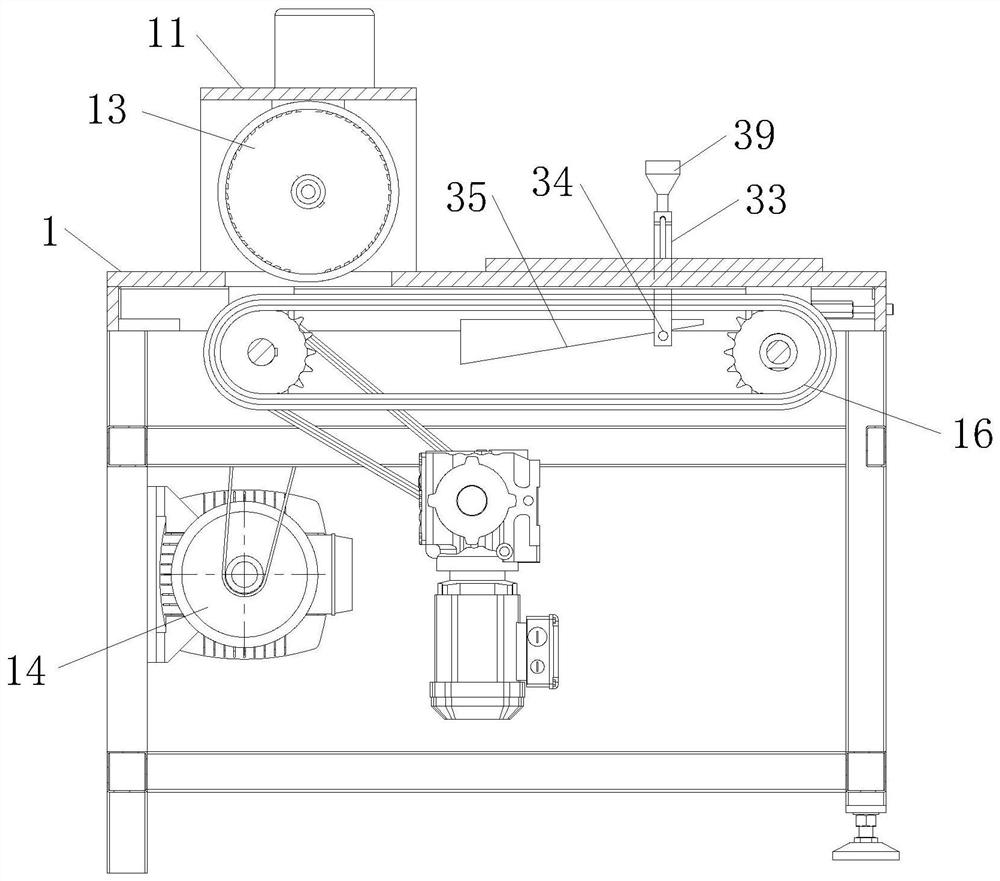

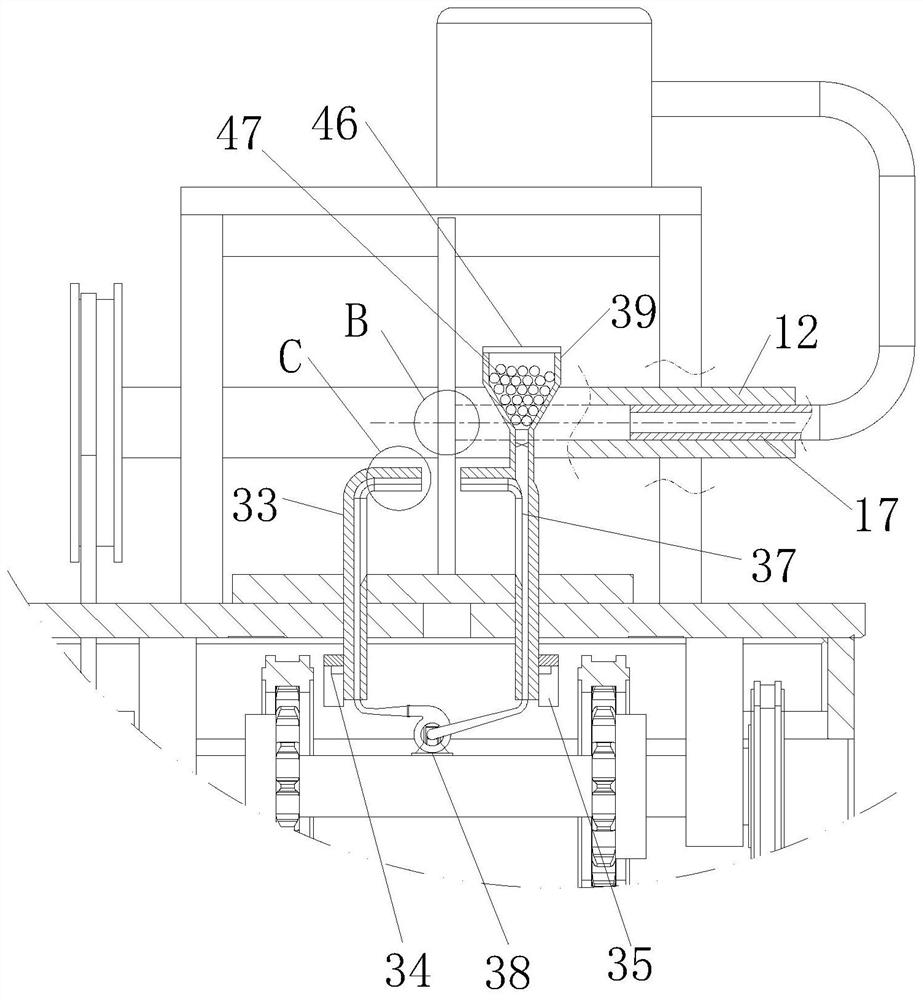

[0031] Such as Figure 1 to Figure 6As shown, a kind of magnetic steel production equipment for motors according to the present invention includes a workbench 1; the top of the workbench 1 is connected to a rotating shaft 12 through a bracket 11, and a cutting blade 13 is fixedly connected to the middle of the rotating shaft 12; A main motor 14 is fixedly connected to the bottom of the table 1 and the corresponding position of the rotating shaft 12, and the main motor 14 drives the rotating shaft 12 to rotate through a belt; the top of the workbench 1 is provided with a slide plate 15 on the side away from the support 11, and the bottom of the slide plate 15 is provided with a horizontal movement unit 16. A clamping unit is provided on the top of the slide plate 15; the rotating shaft 12 is hollow, and an air pipe 17 is sleeved inside the rotating shaft 12, and the air pipe 17 is connected to the rotating shaft 12 in a rotating and sealed manner; Box 18 is communicated with tr...

Embodiment 2

[0040] Such as Figure 7 As shown, a cavity 41 is provided in the sealing strip 4; an ejector cylinder 42 is slidably connected to the water channel 36 at the top of the gripper 33, and the cross section of the ejector cylinder 42 is U-shaped, and the ejector cylinder 42 is connected to the The water channel 36 is in sliding and sealed connection; the end of the ejector cylinder 42 close to the interior of the water channel 36 is provided with a cylinder 43, the fixed end of the cylinder 43 is fixedly connected with the inner wall of the water channel 36, and the piston rod 44 of the cylinder 43 is fixedly connected with the ejector tube 42 The cylinder 43 communicates with the cavity 41 through the pipeline; the compressed air generated in the cavity 41 is charged into the cylinder 43 through the pipeline when the sealing strip 4 is squeezed, so that the piston rod 44 stretches out and pushes the ejector cylinder 42, The ejector tubes 42 at the top of the two grippers 33 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com