Construction method for rapid water plugging and reinforcing near-pit wall of deep foundation pit in loose soil layer

A construction method and technology of deep foundation pits, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of costing money and time, complicating water inrush disasters, and small diffusion range, and achieve the effect of increasing safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

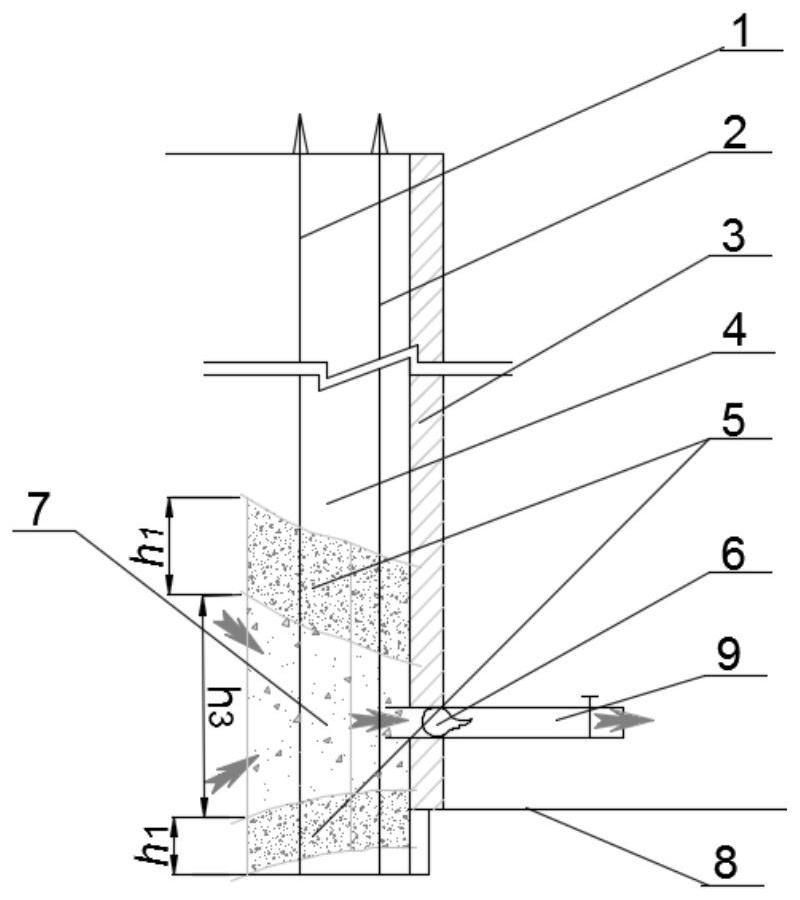

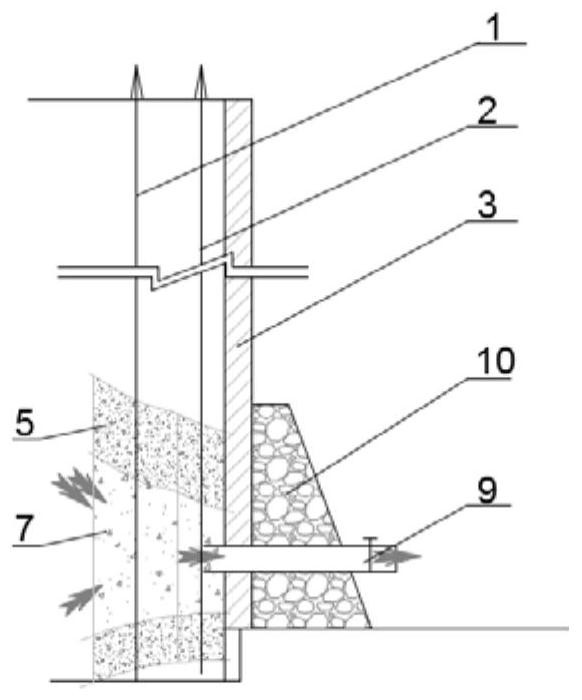

Method used

Image

Examples

Embodiment 1

[0071] When the deep foundation pit of Wanda Station was constructed on Metro Line 3 in a city, when the excavation reached a depth of 15m, there was a large flow of water gushing at 13m, with a water gushing volume of 50-70m 3 / h, the water gushing volume continues unabated for a day. The water quality is black and carries silt, with a silt content of about 10-15%. From the analysis of the survey data, there is a gravel layer below 17m, which is a confined aquifer, and the water quality of the inrush water is the same as that of the gravel layer. Above the gravel layer are clay, silt, and silt layers in sequence, and the water gushing point is located in the silt and silt layers. Due to the large amount of water inflow and a certain water pressure, it poses a great threat to the stability of the foundation pit, and the accumulation of water inflow for a long time also causes the surrounding soil to be emptied by the influx of water, resulting in the risk of ground subsidence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com