Cell culture paper as well as preparation method and application thereof

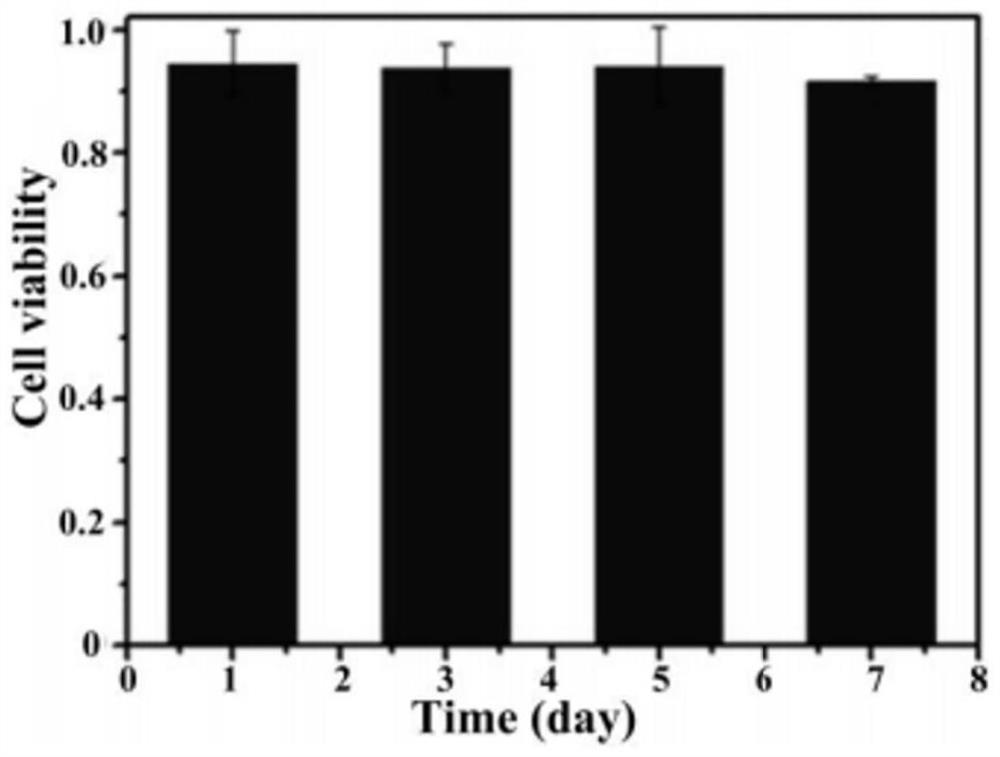

A cell culture and cell culture technology, applied in cell culture support/coating, biochemical equipment and methods, special paper, etc., can solve the problems of small pore size of cellulose membrane, complicated operation, difficult to meet the cell proliferation space, etc. Achieve the effect of small pore size and good water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

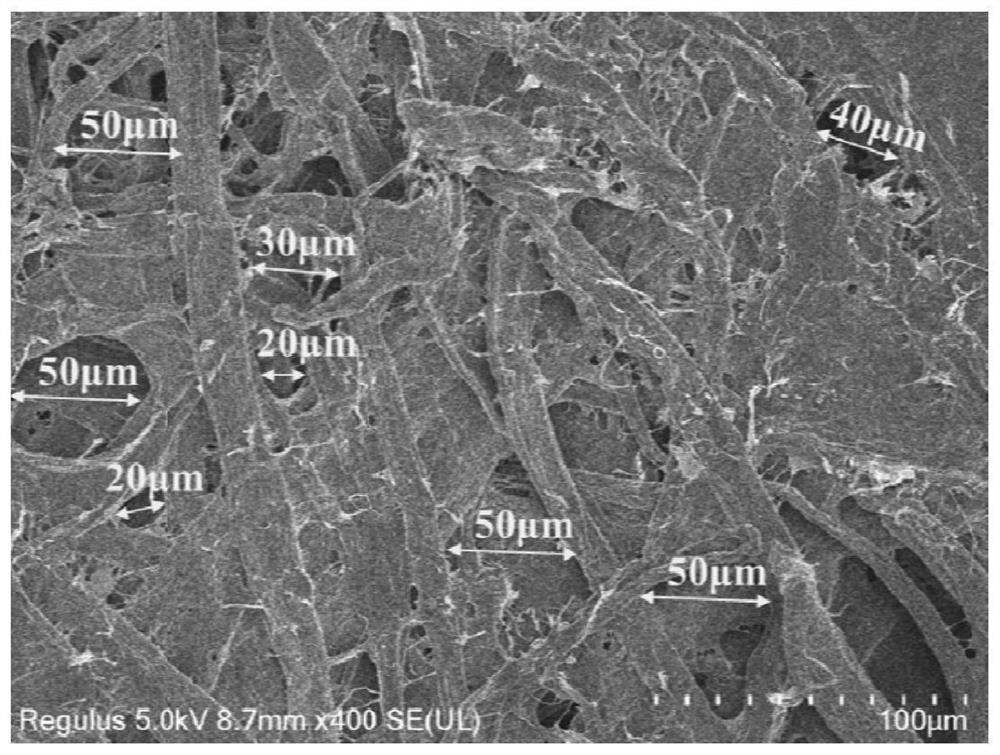

[0028] A method for preparing cell culture paper with adjustable pores of the present invention, specifically comprises the following steps:

[0029] Step 1, the preparation of carboxylated nanocellulose by Tempo oxidation method:

[0030] The cotton fiber after beating is flailed with the concentration of 1% by mass fraction in the standard fiber deflatterer, makes it evenly dispersed, adds the tetramethyl piperidine oxide (TEMPO ) solution and a NaBr solution with a mass fraction of 10%, were mixed and stirred for 10 minutes, and NaClO solution was added dropwise to make the pH of the suspension 10-12, and the whole process lasted for 2.5-3.5 hours. After the reaction is completed, the suspension is washed with deionized water until it becomes neutral to form a carboxylated nanocellulose solution, and deionized water is added to adjust the mass fraction of the carboxylated nanocellulose solution to 0.2% to 1.0%.

[0031] Step 2: Soak the qualitative filter paper with ethano...

Embodiment 1

[0036] A method for preparing cell culture paper with adjustable pores of the present invention, specifically comprises the following steps:

[0037] Step 1) Tempo oxidation method prepares carboxylated nanocellulose:

[0038] The cotton fibers after beating were decomposed with a mass fraction of 1% in a standard fiber de-fiberizer to make them evenly dispersed, and then added 1.6% TEMPO solution and 10% TEMPO solution dissolved in deionized water respectively. NaBr solution was mixed and stirred for 10 min, and NaClO solution was added dropwise to control the pH of the suspension at 11, and the whole process continued for 3 h.

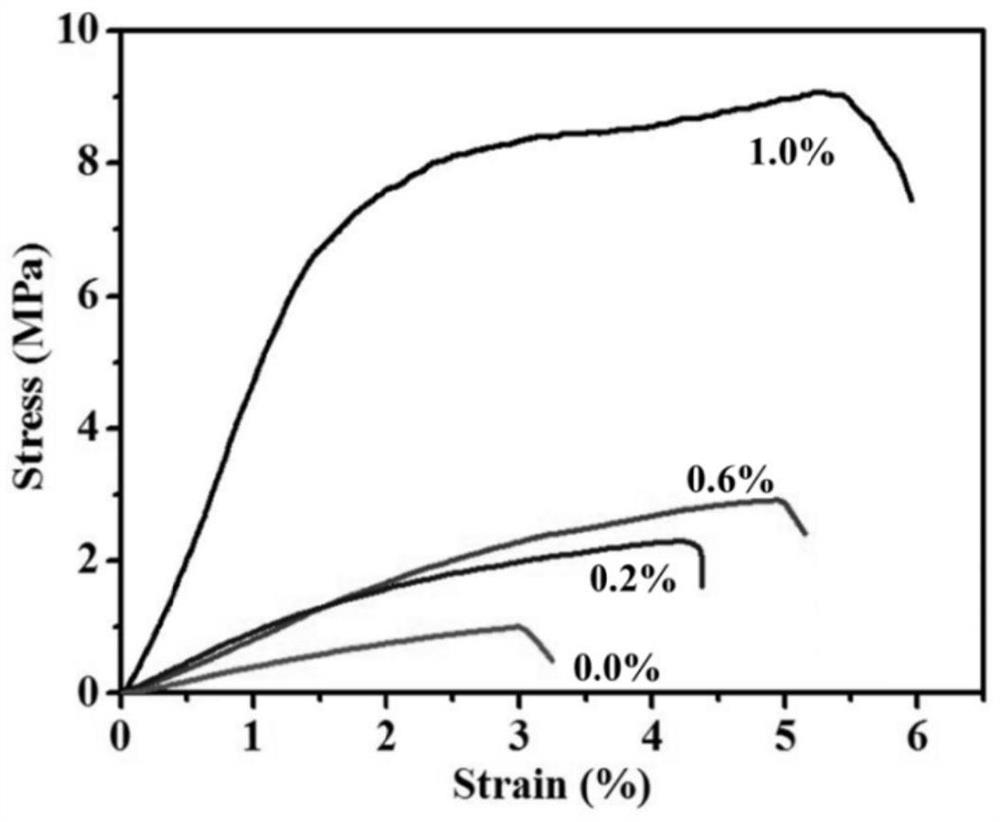

[0039] After the reaction is completed, the suspension is washed with deionized water until it becomes neutral, and deionized water is added to adjust the mass fraction of the carboxylated nanocellulose solution to 0.2%.

[0040] Step 2) Soak the qualitative filter paper with 1:1 (volume fraction) ethanol aqueous solution for 5 minutes to pretreat t...

Embodiment 2

[0045] A method for preparing cell culture paper with adjustable pores of the present invention, specifically comprises the following steps:

[0046] Step 1) Tempo oxidation method prepares carboxylated nanocellulose:

[0047] The cotton fibers after beating were decomposed with a mass fraction of 1% in a standard fiber de-fiberizer to make them evenly dispersed, and then added 1.6% TEMPO solution and 10% TEMPO solution dissolved in deionized water respectively. NaBr solution was mixed and stirred for 10 min, and NaClO solution was added dropwise to control the pH of the suspension at 11, and the whole process continued for 3 h.

[0048] After the reaction is completed, the suspension is washed with deionized water until it is neutral, and deionized water is added to adjust the mass fraction of the carboxylated nanocellulose solution to 0.6%.

[0049] Step 2) Soak the qualitative filter paper with 1:1 (volume fraction) ethanol aqueous solution for 5 minutes to pretreat the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com