Preparation method of TC4 titanium alloy thin-wall high-barrel ring piece or pipe forging

A titanium alloy, thin-walled technology is applied in the field of preparation of high-performance TC4 titanium alloy thin-walled and high-cylinder ring or tube forgings, which can solve the problems of poor market core competitiveness, large differences in forging sizes, and impact on microstructure and properties. Achieve the effect of reducing production cost, shortening production cycle and improving microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

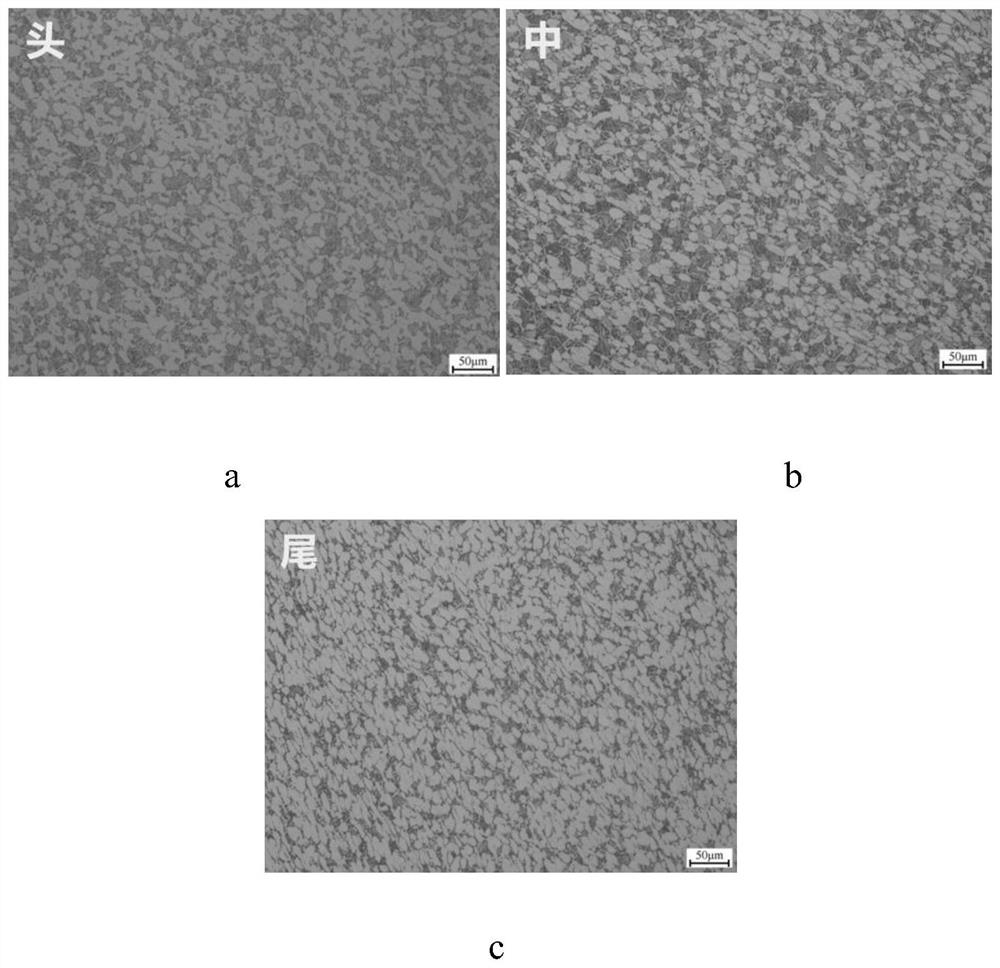

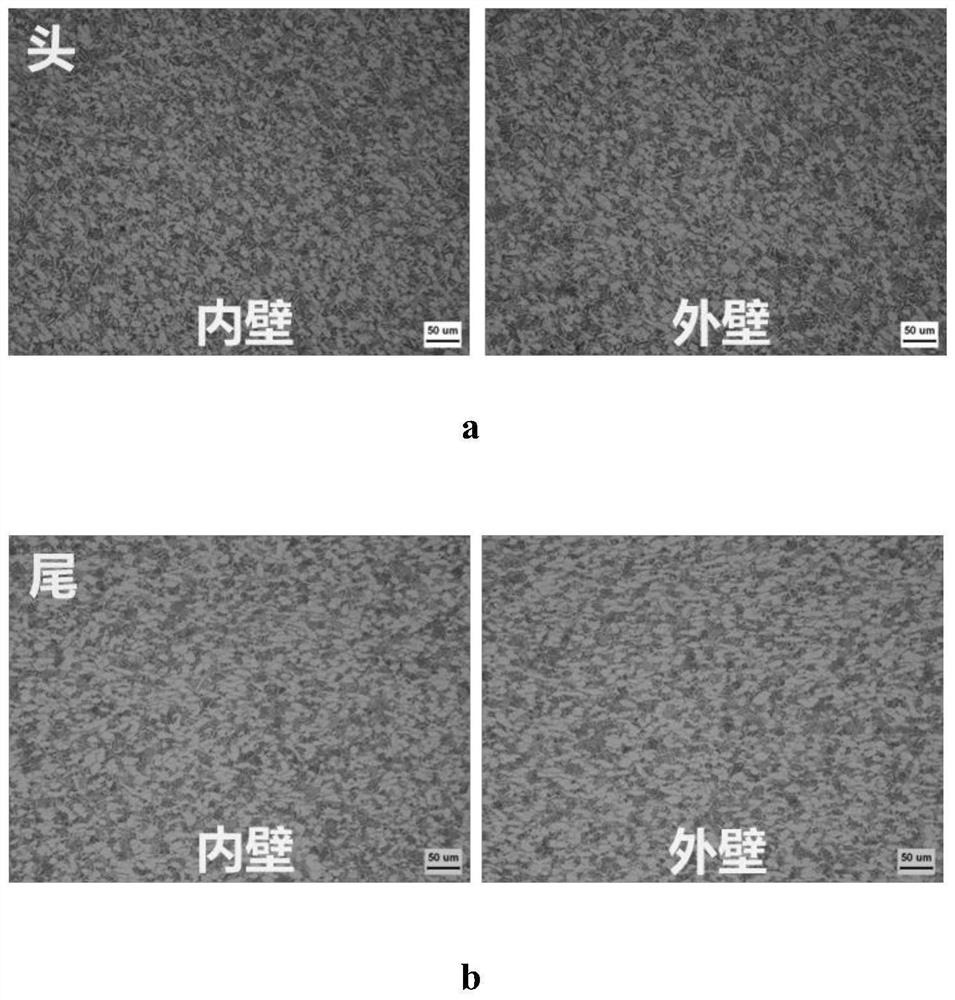

Examples

preparation example Construction

[0022] The preparation method of TC4 titanium alloy thin-walled high cylinder ring or pipe forging of the present invention, its steps are as follows:

[0023] 1) High temperature forging: billet forging, at least 2 times of upsetting and drawing forging, and the cumulative forging ratio is 6-8; among them, the first heating time of upsetting and drawing forging, the heating temperature is 1150℃~1180℃, the heating coefficient is 0.65~0.80, the forging ratio 1.7~2.0, air cooling after the completion of upsetting forging; the second fire upsetting forging, heating temperature 1080℃~1100℃, heating coefficient 0.60~0.75, forging ratio 1.8~2.0, air cooling after completion of upsetting forging. After forging at high temperature, the original as-cast structure of the billet can be fully broken, and a fine β-structure billet can be obtained;

[0024] The heating and holding time can be calculated by the heating coefficient. The empirical formula for calculation is: T=αD, where α is t...

Embodiment 1

[0036] 1) High temperature forging:

[0037] Ingot specification Ф720mm, ingot β phase transition point 990°C, billet unit weight 950kg, billet opening heating temperature 1170°C, heating coefficient 0.65, elongation + upsetting + elongation forging process, forging ratio 1.75, upsetting reduction Speed 15mm / s, air cooling after forging; reheating temperature 1080°C, heating coefficient 0.60, upsetting + elongation + upsetting + elongation forging process, forging ratio 1.85, air cooling after forging. Guarantee that the original as-cast structure is fully broken, and obtain a billet with a fine β structure.

[0038] 2) Low temperature forging:

[0039] Forging at a temperature lower than the β phase transition point of 35°C, that is, the temperature is set to 960°C, and the heating coefficient is 0.7. This fire adopts the process of continuous return to the furnace for upsetting + drawing + drawing, the ratio of upsetting and drawing is 1.65, and the hot material is return...

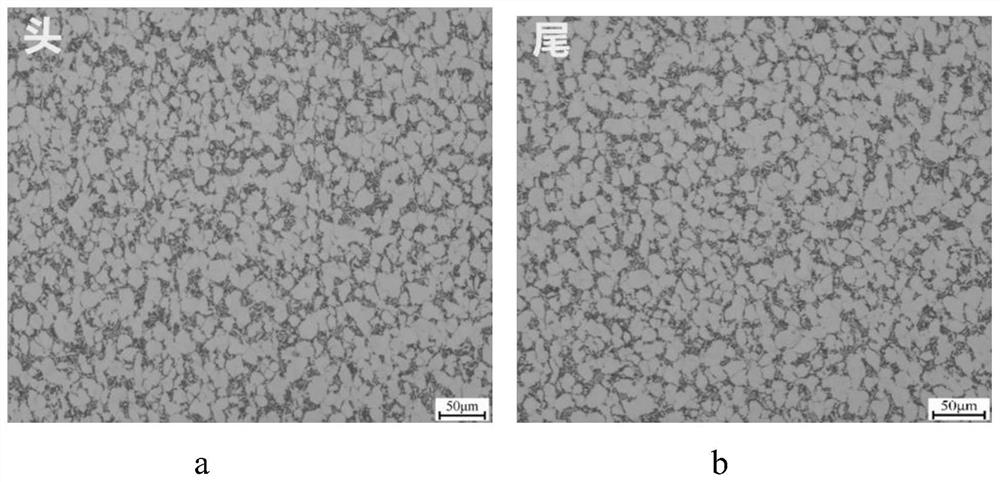

Embodiment 2

[0049] 1) High temperature forging

[0050] Ingot specification Ф720mm, ingot β phase transition point 995°C, billet unit weight 970kg, billet opening heating temperature 1150°C, heating coefficient 0.75, adopting elongation + upsetting + elongation forging process, forging ratio 1.8, upsetting reduction The speed is 15mm / s, the reheating temperature is 1090°C, the heating coefficient is 0.65, upsetting + elongation + upsetting + elongation is adopted, and the forging ratio is 1.9 to ensure that the original cast structure is fully broken and a fine β structure blank is obtained.

[0051] 2) Low temperature forging

[0052] Forging at a temperature lower than the β phase transition point of 30°C, that is, the temperature is set to 965°C, and the heating coefficient is 0.6. This fire adopts the continuous re-furnace upsetting and drawing + elongation process, the upsetting-drawing ratio is 1.7, and the hot material is returned to the furnace for 100 minutes. Air cooling after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com